EDM

2017 Leadtime Leader Awards Honorable Mention: Concours Mold Inc.

This Canadian mold manufacturer identifies teamwork and quality as critical to its ability to drive continued success.

Read MoreAn Added Layer of EDM Knowledge

Understanding electrode material selection and the relationship among the electrode, workpiece material and machine parameters can improve EDM efficiency.

Read MoreMachinery Additions Accelerate Shop’s Growth

Six new Makino machines and updated processes allowed this moldmaker to penetrate new markets.

Read MoreReal-Time Mold Production

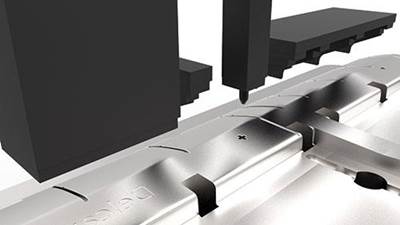

An automated five-axis machining/EDM cell offers a cost-effective alternative to series and batch mold manufacturing.

Read MoreBigger, Faster EDM Capacity Yields Growth

This Wisconsin shop recently fortified its EDM capabilities with the purchase of four new EDMs that offer larger axis travels, faster cutting capabilities and reduced electrode usage.

Read MoreTBT: Integrating Electrode Production

Many companies have an amazing setup in their shops and the machines are running day and night. But one thing still stands out for even the most advanced shops: how slow the EDM process can be.

Read MoreThrowback Thursday: Jig Grinding, EDM or High-Speed Milling?

By examining the advantages, limitations, features and applications jig grinding has compared to EDM and high-speed milling, you will arm yourself with the information you need to make the right decision when it comes to purchasing your next machine tool.

Read MoreJustifying an EDM Upgrade

Advancements in sinker EDM technology may convince you to invest in a new machine, even if your old one is working just fine.

Read More2016 Digital "Technology Review and Sourcing Guide" Available

If it's time to upgrade old equipment, try an alternative process, invest in a new strategy or just shop around, MoldMaking Technology’s annual Technology Review and Sourcing Guide is the perfect companion to your decision-making process.

Read MoreMaking EDM Profitable

The workpiece material and the process parameters of a sinker EDM operation can impact productivity and profitability.

Read More