EDM

Legacy Precision Molds Aims for Ingenuity in Every Job

This Michigan moldmaker strives to deliver quality molds through ingenuity, "nimbleness" and a dose of home-grown integrity.

WatchAnother Look at EDM Generator Technology

Advancements in fully digital sinker EDM generators offer benefits in mold maintenance, process efficiency and electrode wear.

Read More3S for EDM

Applying the sort, set and standardize principles of 5S to EDM operations can increase efficiency by minimizing waste.

Read MoreTaper Angles and Wire EDM

Software can help compensate for excessive erosion during taper cutting with wire EDM.

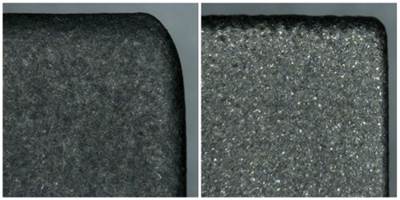

Read MoreAchieving Efficient Filtration

Filters and media choices are key to removing dirt during the EDM process and producing smooth, even finish surfaces.

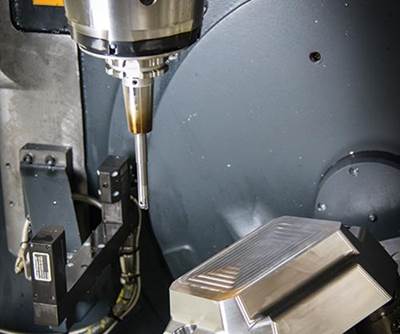

Read MoreEDM Upgrades Enable Faster, Smarter Burns

Intuitive operation, “intelligent” control features, energy savings and raw performance were among the factors driving this shop’s choice of new sinker and wire EDM machines.

Read MoreGraphite vs. Copper Electrode Material for EDM Applications, Part 2

Test findings and a cost of ownership model help identify the monetary impact graphite and copper electrode materials have on manufacturing.

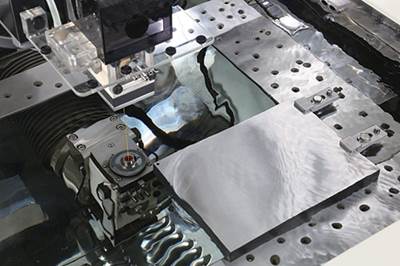

Read MoreTruly Smart EDM

Think ease of use, ergonomics and expertise when empowering your operators with the right EDM.

WatchUser-Friendly EDM Control Technology

Wire EDM machines have taken ease-of-use to a new level, by being equipped with the next evolution of advanced machine control.

WatchIMTS: Automate Your Way out of the Skilled Labor Shortage

GF Machining Solutions is on a mission this IMTS to help industry overcome the skilled labor shortage and stay competitive at the same time. Their solution is automation.

Read More