EDM

2018 Technology Review and Sourcing Guide: EDM

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including EDM.

Read MoreSodick Celebrates the Grand Opening of its North American Headquarters

Grand Opening for VIP’s with a Japanese flair showcases Sodick’s new machining and 3D printing technologies.

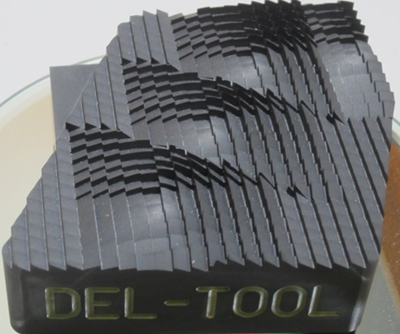

Read MoreElectrodes Highlight Power of Machining with EDM Graphites

The company showcases several machined electrodes of various material classifications to demonstrate the type of machining detail that can be achieved with Poco EDM materials.

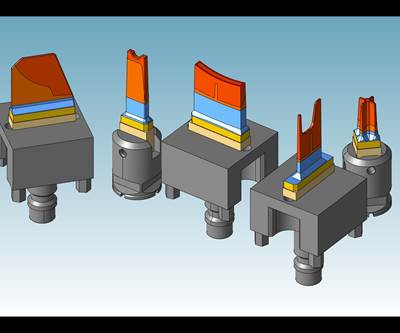

Read MoreCAD Software Automates Die-Sinking Electrode Manufacturing

Advanced CAD/CAM software with dedicated electrode design capabilities greatly reduces electrode design, modeling and manufacturing time.

WatchInternational Perspective: Twenty Years of Tool and Die Making in Europe

The European tool and moldmaking industry has moved from manual to industrial production via internationalization, digitalization, automation and communication.

Read MoreDisplay Features Integration of Machining and Automation

Makino demonstrates graphite machining, EDM and automation in a combination of machine center and production cell at NPE2018.

Read MoreThings to Consider before Investing in New Technology

MoldMaking Technology editorial advisory board member Will Cipkar of Crest Mold breaks down considerations for new technology investments.

Read MoreMilling and EDM Automation Reshape Summit Tooling’s Mold Operations

Summit Tooling President Dan Martin credits the capability to run unattended machining 24/7 to the partnership that his company built with Makino.

WatchTechnology Tuesday: EDM Success

Cruise through this week’s Technology Tuesday slideshow to see EDM units that shops across the country have used to increase capacity and leverage greater efficiency in their processes.

Read MoreEDM Machine Has Power Optimizer to Reduce Machining Time

The Edge2 EDM machine from Makino incorporates SuperSpark4 and Intelligent Expert System technology for increased accuracy and efficiency.

Read More

_MMT.jpg;maxWidth=400;quality=70)