EDM

Soft Wire Threading for Wire EDM’ing: Tips for Success

Look for EDM equipment that provides improved wire processing during the AWF cycle. Technology should include a way to precisely control the wire tension and energy used to cut the wire.

Read MoreMega-Cell: Moldmaking Automation

The Mega-Cell is a production system that ties together all available opportunities to automate and control the process.

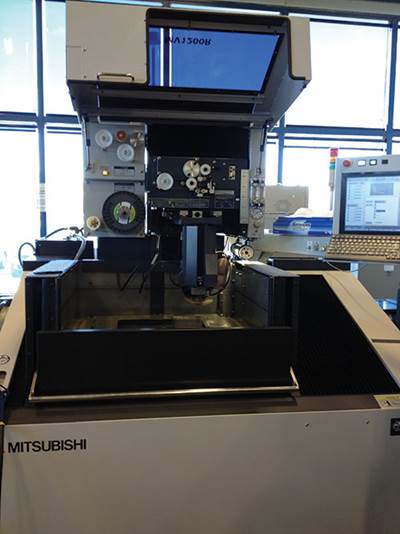

WatchNew EDM Pushes Performance and Precision

“This machine has changed wire EDM in a way that the machines I’ve operated have not been able to do, because it cuts substantially faster than its predecessors, yet it consumes about 40 percent less wire.”

Read MoreRaising the Bar on Better

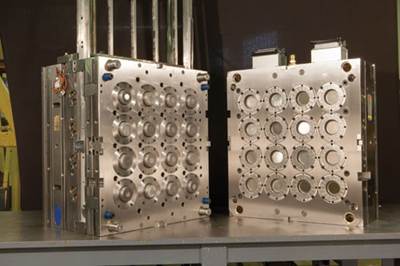

A look at one project to move away from traditionally customized moldmaking toward a level of complete automation that raises the bar on accuracy, repeatability and control.

WatchTraditional Labor Values Meet Linear Technology

What GW gained was high reliability, improved speed/throughput without sacrificing accuracy or quality and a high level of satisfaction from the operators, on all the machines.

Read MoreUnderstanding the Total Package of the EDM Production Process Is the Key to Raising Productivity

The best way to determine the training best suited to your company is to find out what your customers need.

Read MoreHow EDM Training Can Boost Productivity

Even the shortest of training sessions provide the opportunity to recover any costs incurred in a very short time.

Read MorePrecision Mold Shop Doubles EDM Capacity and Triples EDM Output

Janler’s business philosophy centers on “running the operation as a business, not a shop.

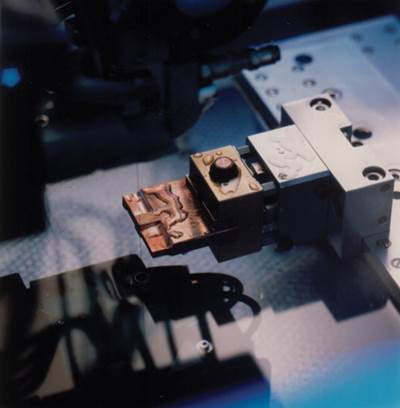

Read MoreHow to Produce Consistent, Repeatable Electrodes

When it comes to electrode production, workholding and automation technology must be accurate and consistent to ensure repeatability and reduce machining time.

Read MoreEDM Efficiencies Excel

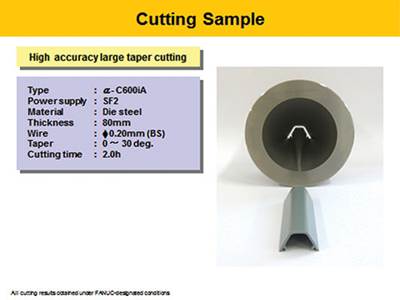

Advancements in EDM processes in terms of machining speed and surface finish improve overall accuracy, productivity and profitability.

Watch