Real-Time Mold Production

An automated five-axis machining/EDM cell offers a cost-effective alternative to series and batch mold manufacturing.

Today’s mold builders must focus on quality, cost and delivery in order to improve productivity and remain competitive in the marketplace, but how is this best accomplished? In the past, moldmaking revolved around the individual skills of master moldmakers, but today that pool of craftsmen has grown ever smaller, and fewer or no replacements are entering the market. Shops end up having highly skilled tradesmen operating an EDM for 10 hours a day instead of running unattended 24 hours a day, or they add a second or third shift and are challenged with ensuring the same part quality across all shifts. Let’s face it, one highly skilled craftsman operating one or two machines for an entire shift is not very cost-effective.

Then there is the matter of time and delivery to market. Still today, mold construction is completed in series. This means parts are rough-machined on various pieces of equipment (knee mills and CNC VMCs) then heat-treated. This is followed by finish-machining on surface grinders, machining centers, and wire and sinker EDMs, and then mold polishing. This series manufacturing also includes electrode design and manufacture, after the number required for each detail is determined. This might include, for example, one roughing electrode for each part and two electrodes (or more) to finish the detail. Better yet, three finishing electrodes per part plus a few spares is a smart way to go, just in case. You don’t want to be caught short in the middle of a run and have to make more electrodes.

The series approach can also be combined with batch manufacturing. This entails setting up a part at a certain orientation and machining a feature on all of the parts, then breaking down the setup and repeating, machining another feature at a differ-

ent orientation. When the batch of parts is complete, the process is repeated again for another feature or orientation. The mold is not complete until the last part in the batch is machined in the final setup. The manual setup and tear-down of the operations for this approach increases both time and costs.

An Automated Alternative

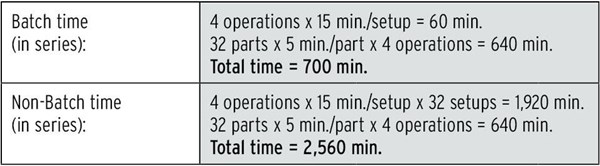

Take, for example, a 32-cavity mold for which the operator sets up the first operation and machines all 32 parts before moving on to the next operation. Each part goes through four machining operations, in series. Each setup for the operation takes 15 minutes, and each operation takes five minutes:

A more specific example involves machining an individual mold cavity. First, the operator drills water lines from the backside of the cavity. Second, he drills and taps connecting water lines from the side of the cavity. Third, he rough-machines the parting-line features from the top of the cavity. Fourth, he sets up the cavity on an angle to machine the subgate. All four operations require a different part orientation and setup. If the operator machined only one part at a time, moving through all the necessary operations would dramatically increase overall machining time.

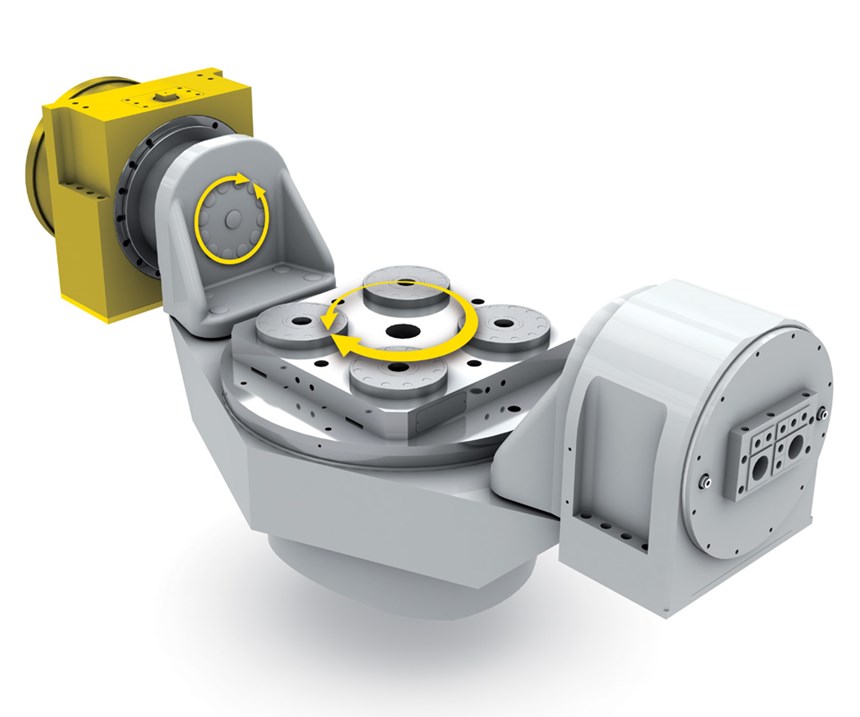

An alternative approach to series and batch manufacturing is to marry the use of modern machining technologies and automation, such as with five-axis CNC machining. This in itself is an automated process that improves process efficiency, as it permits a mold component and/or electrode to be machined in one workholding device that is specifically designed for five-axis machines. This system design allows access to the workpiece and electrode so the operator can machine as close to 100 percent of the part as possible. In this approach, the operator basically fixtures the part so it is held on only one side, then, using five-axis machining, orientates the part at various angles to machine all the required features. The fourth and fifth axes position the part, while the machine’s tool magazine has ample space to store all the necessary tools required to machine the components.

In addition, five-axis-machine tables can be programmed to automatically position the part at the correct orientation and perform the needed machining operations, or all five axes can be programmed to move and cut simultaneously to machine a 3D feature. Part production can run around the clock with a minimal number of operators, as these machines can produce the necessary components while running unattended during off hours and weekends. A stand-alone machine (one without automation) can run unattended until the program/cycle is complete. The longer the cycle, the longer the unattended time.

However, once the cycle finishes, the machine will sit idle. With automation, once the cycle is complete, the part can be unloaded, a new part loaded and a new cycle initiated. This results in extended machining time without operator intervention.

Using high-precision five-axis machines can also increase part quality, because there is no reliance on the individual skill sets of craftsmen. Instead, automated probing systems that use macro programs in the control can check part dimensions and tool wear, serving as a sort of quality control insurance. For example, if a part is not within tolerance, the tool can be checked for wear and the tool offsets then adjusted. The part will be remachined with the compensated tool. Or, if the tool is broken, the CNC control can change to a redundant tool to finish the machining process. The macro programs use “if” and “then” statements to determine if the part is oversized and then scan the tool with the laser tool setter.

Electrodes can also be probed for size, and that data can be stored on identification chips on the electrode holder and then read into a CNC sinker EDM for burn-setting adjustment.

Parallel Operations

To improve productivity and address time and delivery constraints, mold manufacturers might consider an automated work cell that combines a five-axis CNC machining center with a CNC sinker EDM. This type of setup enables “real-time” production of a mold.

The use of a five-axis machining center, automation and EDM eliminates the need for a batch approach, allowing for a truly parallel system. You don’t need to cut all the electrodes at one time. You can cut them on demand. You don’t need to finish the last batch of the last operation, in series, and then send the components to polishing. You can send each one when it is ready. You can start mold assembly sooner, because you do not have to wait until a series and/or batch process is completed.

In this automated work cell, both machines use the same workpiece clamping system, which consists of a base plate (receiver) accepting pallets that either have the mold components mounted on them or an electrode clamping system. Robots tend (load/unload) the five-axis and EDM, loading pallets full of mold components into machining centers or onto sinker EDM tables. Electrodes can be loaded into the five-axis for machining, stored, and then loaded inversely into the sinker or its electrode carousal.

The cell is scheduled through a database server, or cell controller, and the process flow becomes dynamic instead of batch. This is also referred to as flow production. The parts/components flow continuously from one operation to the next, without all parts in the batch having to complete one before moving to the next operation.

To illustrate, say the five-axis finish-machines a cavity, and that cavity is then automatically loaded into the sinker EDM. The five-axis then cuts an electrode that is automatically probed for size. The related information is read into the read/write chip, and the electrode is unloaded from the five-axis and automatically loaded into the sinker. Electrode sizes are read into the sinker control for proper orbit setting.

This approach requires the manufacture of only a minimal number of electrodes for roughing and finishing the detail work, which are then placed in storage for the sinker. The hardened component (a heat-treated cavity, core or side action, for example) is scheduled into the five-axis machine for hard milling. When the machining cycle is complete, the component enters the queue (or storage area of the automated cell into which parts are placed on racks temporarily until they are needed) to be sent to the sinker. That is where electrodes made only a few hours earlier will carry out the finishing of details that were unable to be completed in the mill. If additional electrodes are required, the computer control simply schedules the machining of those electrodes, so as not to interrupt the machining flow.

Transitioning from series and batch processes to an automated, precision five-axis CNC machining and CNC sinker EDM cell enables production of mold components in real time, 24/7. This can reduce manpower, decrease production time, improve quality, provide consistent products and shorten time to market.

Related Content

Precision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More