Bigger, Faster EDM Capacity Yields Growth

This Wisconsin shop recently fortified its EDM capabilities with the purchase of four new EDMs that offer larger axis travels, faster cutting capabilities and reduced electrode usage.

Triangle Tool Corp. in Milwaukee, Wisconsin, does everything big. Housed in a sprawling 215,000-square-foot building and employing 160, the company manufactures molds topping 1,000 tons for consumer goods, waste cans, storage containers, appliances and other products. Recently, the company fortified its EDM capabilities with the purchase of four large Sodick machines, bringing its total EDM count to seven.

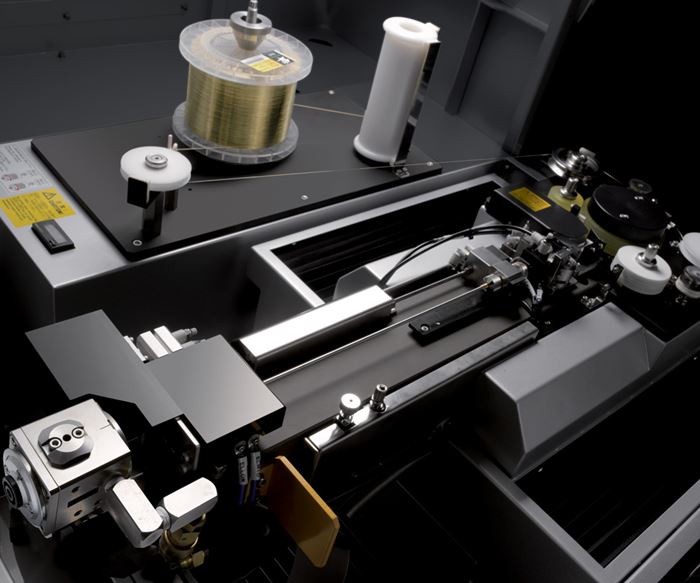

The new additions include AG60L and AG100L sinker EDMs, and an AQ900L wire EDM, but the capstone investment was the AQ1500L extra-large wire EDM. This machine, with its 59-inch X axis, is the largest wire EDM ever made by Sodick.

Triangle says this new arsenal of wire and sinker EDMs, with their larger axis travels, faster cutting capabilities (even on hard-to-machine materials) and reduced electrode usage, is helping the company keep up with the increasing demands for higher productivity and the greater capacity necessary for it to grow.

Maximized Capacity

The AQ1500L has already helped Triangle to win new business for larger, heavier molds that it says would have been significantly more difficult to win before. For example, the supersized-mold-manufacturing work it previously outsourced required the use of a crane for support, even at the vendor’s facility. While the company’s then-largest EDM, the AQ900L, can handle a maximum weight of 4,400 pounds, the AQ1500L’s worktable offers a maximum capacity of nearly 18,000 pounds.

The large machine features XYZ travels of 1,500 by 1,000 by 600 mm and thicker plates that incorporate lifter features. Full-length UV axis travels allow for a 45-degree taper on very thick workpieces. The company recently used the machine to cut 10.9-inch-diameter slugs from a 39-inch block of difficult-to-machine molybdenum. Just prior to that job, the AQ1500L was used to cut donut-shaped injection mold cavities of roughly 18 by 24 inches in size. The company says its older EDM models limited UV travels to about 75 mm, making it difficult to achieve high taper angles in large workpieces. “The combination of a sturdy worktable with larger axis travels and improved tapers for thick plates made the AQ1500L stand apart,” says Daniel Gougé, Triangle vice president.

The machine also features a 44-pound wire spool capacity necessary to run larger jobs, EDM ceramics and Sodick’s rigid linear motor axis drive technology. According to Sodick, this technology helps improve accuracy on nearly all sinker EDM applications. “Rigid linear motors achieve an acceleration fast enough to produce their own flushing conditions without the need for additional jump features to boost axis movement,” says Alan Losch, applications support engineer at Sodick. “This is possible due to the direct-drive motion of rigid linear motors, which eliminates mechanical forces in favor of a direct magnetic force. By eliminating mechanical forces within the drive, the drive’s responsiveness is greatly improved in comparison to ballscrews, while wear and thermal distortion along the axis are eliminated, allowing for uninhibited drive acceleration.”

“Smart” EDM

Triangle’s senior EDM manager, Larry Schladweiler, says the easy setup and adaptive control features eased the transition to the new Sodick machines. The adaptive controls also improved the company’s ability to quickly and accurately cut difficult materials such as MoldMax, with which it previously had had problems associated with arcing. Arcing is the continuous flow of electrical current between an electrode and a workpiece, usually resulting in uneven electrode wear and subsequent pitting of the workpiece, a potentially expensive problem. In the past, the company reduced this risk by using “fuzzy logic” adjustments, Schladweiler says, and even with these adjustments, engineers had been forced to slow the process down to further minimize the risk.

Sodick’s adaptive control automatically reduces risks such as arcing because it is part of what Sodick refers to as “smart” technology: control software that intelligently guides users to the proper cutting conditions through the use of simple questions about the intended application.

According to Shingo Watanabe, Sodick applications engineer, “This system works in tandem with the aforementioned rigid linear motors and is controlled by Sodick’s motion controller technology, which continually monitors and adjusts the cutting and movement performance in real time. Finally, an arc-less discharge system continually evaluates the spark gap for optimal performance. Together, these systems create cutting conditions which minimize arcing, improve flushing to further reduce risk and adjust machining based on real-time feedback.”

Faster, More Efficient Cutting

Adding the Sodick machines also has helped Triangle reduce by one-third the average number of electrodes it needs to complete a given job and increase cutting speeds by as much as 35 percent, the company says.

Sodick’s “Zero Electrode Wear” technology is designed to rapidly increase and prolong discharge “on” times by stabilizing the voltage and spark control, thus causing virtually zero electrode wear, the company says. On one particular job that specified the machining of ¾-inch-deep ribs with 0.007-inch thickness, Triangle says this zero-wear feature enabled it to reduce the quantity of electrodes needed to complete the job from three to two.

Insulating ceramic components that are standard on all Sodick EDMs also prevent the discharge from “leaking” away from the workpiece, and that, together with the rigid linear motors, contributed to Triangle’s significant gains in machining speed, the shop says.

On the wire EDM side, Triangle says it experienced a 33 percent improvement in cutting speeds, and the reliable automatic wire threader (AWT), which is standard on all Sodick wire EDMs, proved to be an especially notable advantage. “We have a regular consumer goods order that requires threading for a 15.5-inch-tall part. We have been fulfilling this order for 12 years and long ago had given up trying to thread such a tall part with an automatic threader. The new Sodicks’ AWT can do it without missing once,” Schladweiler says. Gougé adds that one of the biggest advantages in terms of threading precision is its superior ability to control pitch, which makes the threader much more precise. This is because the tight tolerances of Sodick’s AWT system ensure threading accuracy in a way not possible with open- or loose-tolerance systems. For parts requiring extreme precision or straightness, which would include tall or hollow parts like those Triangle produces, this is fundamentally important.

Schladweiler says one of the biggest surprises during the transition to the new Sodick machines was that the AQ900L wire EDM could achieve a cutting speed with brass wire that had previously only been possible with a gamma-coated wire.

The difference between coated wire and plain brass wire can be considerable, he explains. The maximum cutting speed of a wire is determined largely by its zinc content. To improve cutting speed without sacrificing the durability of the wire, brass wires are often coated with high-zinc alloys. An example is gamma-coated wire, which is comprised of 65 percent zinc and 35 percent copper. Such coatings in some cases can improve wire cutting speed by as much as 20 percent over plain brass wire. However, by controlling the strength and frequency of discharge pulses, Sodick’s circuitry can improve cutting speed and accuracy over traditional discharge methods, Schladweiler says, which is what has allowed Triangle to greatly improve its cutting speeds with plain brass wire.

“Overall, these four new machines have improved lead times, particularly on jobs and materials that had previously been challenging,” Gougé says. “They’ve reduced the number of required electrodes, which keeps our electrode costs down, and bettered our bottom line by allowing us to keep more of our heaviest EDM work in house.”

Related Content

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreAdvantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

Read MoreHow to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read More6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreRead Next

3S for EDM

Applying the sort, set and standardize principles of 5S to EDM operations can increase efficiency by minimizing waste.

Read MoreMaking EDM Profitable

The workpiece material and the process parameters of a sinker EDM operation can impact productivity and profitability.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.jpg;maxWidth=300;quality=90)