Justifying an EDM Upgrade

Advancements in sinker EDM technology may convince you to invest in a new machine, even if your old one is working just fine.

In the machine tool world, the sinker EDM is like a military tank, and in many mold shops the oldest CNC machine in use is often a sinker EDM. They have few moving parts and a very robust electrical system that allow them to continue to make good parts for a long time. This makes it difficult for a company to justify the cost of upgrading technology. In the end, however, even the best-kept machine reaches a point where performance, throughput, accuracy and quality concerns tip the scales toward purchasing new equipment, and advancements in sinker EDM technology can help justify a new machine.

Spark

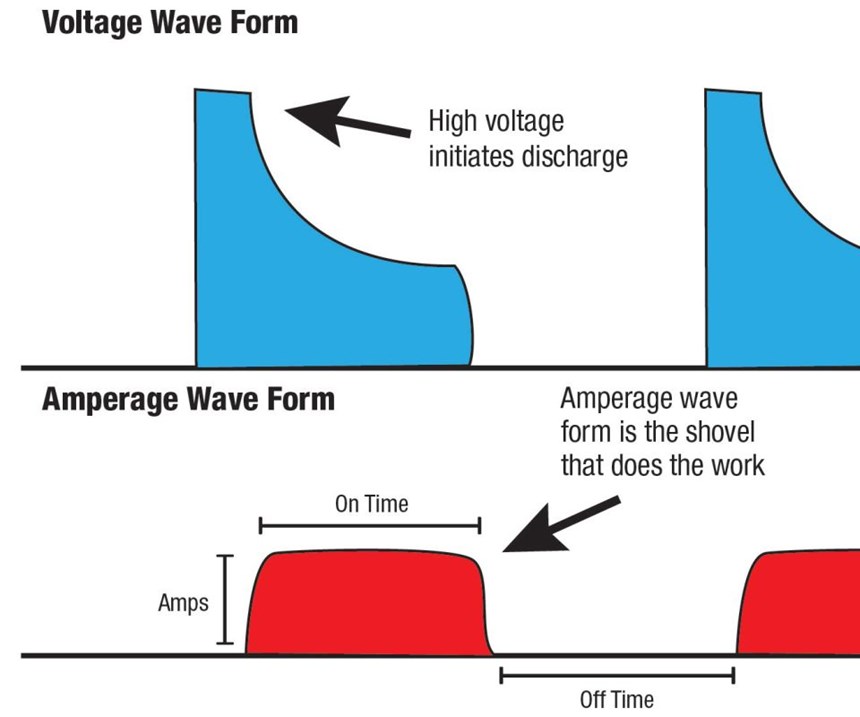

A good way to describe the material erosion process of an electrical discharge machine is to think of the EDM spark as a shovel. Whether you are digging a hole or electrically removing material to form a cavity with an EDM, you remove material one shovel, or one spark, at a time. To dig a hole/cavity faster, you can use a bigger shovel (more power) or shovel faster (shorter pauses between sparks) or use a different-shaped shovel (electrical waveform; see Figure 1).

When you consider that the speed of the EDM process may vary from 1,000 to 150,000 sparks per second, a machine that helps you choose the correct waveform, select the maximum power allowable by geometry, and automatically adjust the flush and cooling time between sparks is a pretty difficult machine to beat.

The EDM process, much like other metal-removal processes, presents two main difficulties that must be overcome: heat and contamination. Each tiny spark creates heat, and the more power and the higher the frequency of the spark, the more heat is created. A good spark should take a large shovel out of the workpiece and a very small piece of the electrode. Those hot particles that are removed are contaminants that can damage the electrode or workpiece. The latest EDM technology recognizes that there is a difference between molten hot contaminants and swarf that has cooled and can be used to improve spark initiation.

Look for a machine that can self-adjust as spark conditions change to find the fastest speed and lowest wear on electrodes.

The EDM process can only initiate sparks as fast as contaminants and heat are removed. EDM dirt that builds up in the cavity has to be removed before you can continue digging. The deeper the cavity, the more difficult it is to remove the dirt.

The electrical discharge process is a series of well-tested predictions for how far the spark will travel into the workpiece. The larger the spark, the more variable the spark penetration, depending on the electrode material used, the material being machined and the flushing conditions. So, if there are a lot of contaminants in the dielectric oil, the spark can travel farther during a roughing process and possibly leave behind rough areas that won’t clean up.

The spark discharge voltage varies according to gap conditions. Any new sinker EDM should be able to read the voltage of each spark and recognize when discharge is irregular due to unwanted gap conditions. Fine control of spark penetration, even with the most powerful sparks, means you can shovel closer to your surface with your large shovel and leave less material for the smaller scoops to remove. The practical effect is leaving less work for the finishing settings, which means less electrode wear and faster speeds to get to the same finish for which you are aiming.

Speed

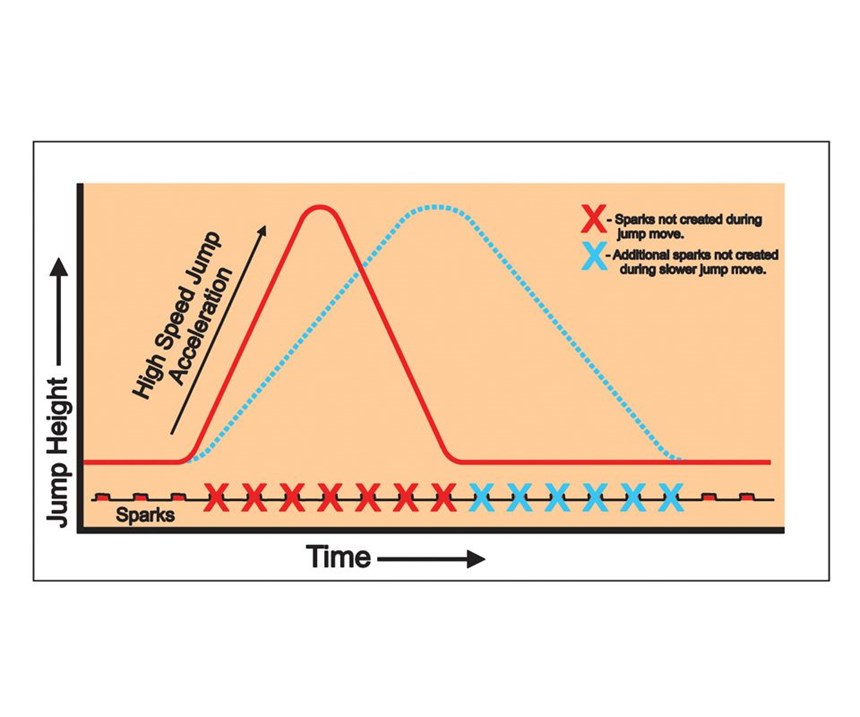

Newer machines offer ever improving jump speeds because that is the low hanging fruit for improving burn times. Better jump speeds allow better contaminant removal, using the electrode surface tension and hydraulic force to pull contaminants out and fill in the void with cool clean oil (see Figure 2).

It is easy to see that the faster the machine “jumps away” and gets back to machining, the more sparks will be thrown. Therefore, the shorter the time the machine breaks to rest, the more shovels of material get removed. The modern EDM can move between 20 and 35 m/min. (787 and 1,380 ipm). The top speed is important, but equally important is how fast the machine accelerates to that top speed. Accelerations between 1.0 and 1.6 G are now industry norms.

People often underestimate the importance of this acceleration. Ask any drag racer, and he or she will tell you that it’s not miles per hour that win a race, it is acceleration. Keep in mind that these superfast jump speeds are only useful for small electrodes. As electrodes get larger, the hydraulic forces increase exponentially. A good machine should take into account surface area and adjust jump speed to the fastest at which an electrode can move without damage to the graphite.

Wear

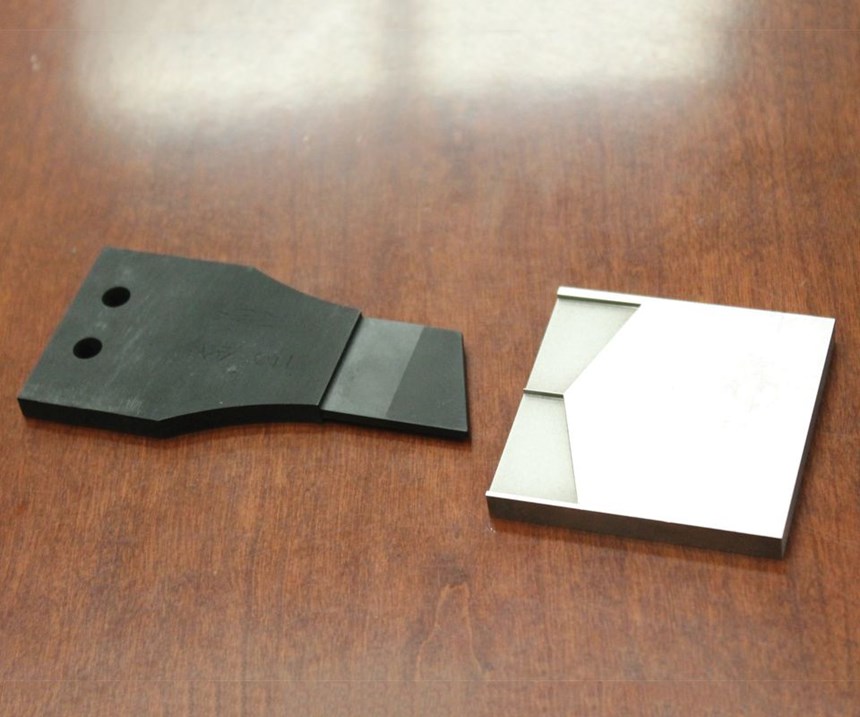

The more complicated the molded part, the more detailed and expensive the electrodes needed to create those cavities. Reducing wear on electrodes has become a big selling point for EDMs, and the cost savings on electrodes can justify the cost of a new machine. Some EDM manufacturers have created special circuitry to achieve lower electrode wear by making effective use of longer spark durations.

The machine’s electrical hardware can change the wave’s shape and spark length to maximize material removal and minimize electrode damage on a micro-second level. Turning to the shovel analogy again, new low-wear circuitry allows for a custom-shaped shovel for each and every shovel load, which maximizes hole-digging efficiency. As a result, where you may have been using three electrodes to achieve a specific finish and tolerance, you can now achieve the same detail and quality with two electrodes. The days of using two roughers and four finishers are long gone. In machining a 64-cavity mold, for example, the reduction in graphite usage and manufacturing time can lead to significant savings.

In addition to cost savings, another benefit of reduced electrode wear is improved dimensional accuracy of the cavity. There is no need to chase the last 0.0005 inch to achieve a close-tolerance burn.

Waveforms

Specialty materials such as polycrystalline diamond, cubic boron nitride, ceramic matrix composite and carbide are some of the most difficult materials to machine because of the electrical resistance and thermal conductivity produced. Specialty waveforms have been developed that can improve machining of traditionally difficult materials used in the molding industry, such as Moldmax, Ampcolly940 and Ampco18 and other high-heat-transfer molding materials.

Just as you might need a special shovel (a jackhammer, for example) to remove difficult construction materials, you might need to use a special machining circuit that produces unique amperage waveforms to remove difficult molding materials. These circuits allow the machine to break up and remove the materials without producing a lot of heat that is quickly dissipated through the material or would negatively affect the material’s structural integrity.

Molders and moldmakers are always looking for better release of plastic parts from molding surfaces. To meet this demand, some EDM manufacturers have developed special waveforms that can create a shiny, textured finish to ease mold release. This technique was developed in Japan for production molding of phone devices that require a large flat area and excellent mold-release properties. The amperage waveforms create a spark (or shovel), that makes a very wide and flat divot, resulting in a shiny finish without polishing, but a finish that also releases similarly to a polished surface.

Also, as the size of plastic parts decrease, with smaller corner radii and finer finishes, it becomes necessary to create tiny power pulses and very small sparks to remove a very small amount of material. This produces finishes with surface roughness to 0.05 micron.

High-end EDMs are designed with granite or ceramic tables and short power-feed cables to limit the machine-effect capacitance and yield surface finishes that an older EDM couldn’t even consider. Standard machines act as a capacitor that absorbs or stores the nano-pulse sparks, building them into a larger one. If the standard finishing spark is a hand shovel, think of a nano-pulse spark as a tablespoon.

Controls

Modern mold shops have become more competitive by having fewer people run more equipment, and today’s EDMs are easier to run. The operator of older EDMs has become a real specialist, as aging equipment is less user-friendly and often more difficult to navigate. An older EDM requires an experienced operator who knows all its quirks and unique functionality. The problem is that as the machines age, so do their operators, and many eventually may be looking to retire. The EDM process always needs quality employees in order for it to be performed successfully. New controls are more menu-driven and allow operators to become quickly proficient at machine operation. Being able to manipulate settings for the correct surface area, flushing and undersize is important for achieving good results, and the modern EDM allows operators to create custom settings by filling out a menu-driven form, making it much easier to achieve those great results.

Test it Out

Improved jump speeds and ease of operation are factors that moldmakers can easily observe, but the best improvements in modern EDMs are under the hood, in the areas of electronics, processing speed, and waveform creation and adjustment. The EDM process might be very complex, but the results speak for themselves. The best way to determine if it is time to upgrade your EDM to the newest technology is to offer a supplier your most common and challenging cuts and see how the new technology

performs.

Related Content

How to Determine the Proper Vent Depth

Vent depth is critical to optimizing mold performance, so here is one approach to finding that elusive right number.

Read MoreHow to Correctly Size a Hydraulic Cylinder

This week Randy shares steps for correctly sizing a hydraulic cylinder on a mold.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreMold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

Read MoreRead Next

EDM Upgrades Enable Faster, Smarter Burns

Intuitive operation, “intelligent” control features, energy savings and raw performance were among the factors driving this shop’s choice of new sinker and wire EDM machines.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More