Mold Components

Today's Tools for Tomorrow's Technology Leaders

As you investigate investment in capital equipment, training, services, or a myriad of other technology items, turn to this guide for assistance.

Read MoreConsider the Advantages of Using Standardized Slides

The benefits of using standard slide assemblies are realized by the moldmaker and the molder. It is a proven way to save time and money for both users.

Read MoreModular Side-Action System in Medical Part Molding Reduces Downtime, Cycle Times

Case Study/Mold Components, Medical.

Read MoreAlt Method of Actuating Injection Mold Core Pulls and Slides

Improve efficiency and speed with hydraulic locking core pull cylinders.

Read MoreBaffle Blades in Plastic Injection Molds

Turbulent-flow plastic baffles eliminate blow-by, significantly improving cooling and cycle times.

Read MoreConfigured Components Help Save Time And Costs, and Maximize Efficiency

How to achieve big cost and time savings in your mold work by streamlining the mold design and ordering process. How using standard mold components can enable you to spend more time designing and building molds instead of all the components that go into them.

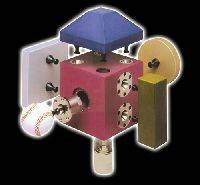

Read MoreChangeable Mold Base Offers Flexibility, Productivity While Reducing Tooling Costs

A mold base has been designed that provides faster production changeovers.

Read MoreQuick-Change Devices Reduce Setup Time

A line of quick-change devices has been developed that serves as a replacement for traditional nuts and bolts and can reduce setup time.

Read More