Mold Components

Achieving Accurate Temperature Control with Your Hot Runner Controller

The right hot runner controller is key to producing high-quality, complex medical parts.

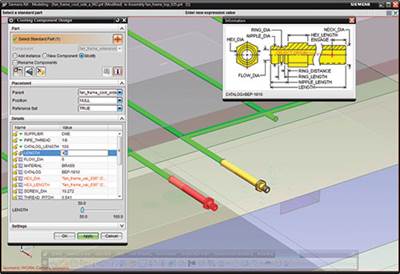

Read MoreThe Value of Insourcing and Standardizing Component Work

To become more competitive, this mold manufacturer established a components division to build a growing selection of its own mold components.

WatchCarving out Savings at the Front End

Positive-geometry cutting tools help this shop double-down on a key time-saving strategy by reducing machining time on aluminum MUD frame inserts.

WatchDesigning and Building Molds for Aerospace Requirements

The aerospace industry has some unique requirements for many of its plastic components, primarily because of the thermal expansion challenges these materials present.

Read MoreStaying One Step Ahead of Customer Needs

The key to optimal customer support for any mold manufacturer is doing more—from upfront design engineering during the initial stages of product development to emergency mold repair services. And this is exactly the business model Kansas City-area blow moldmaker Creative Blow Mold Tooling offers.

Read MoreFor Better Mold Venting, Start with the Metal

Selecting the right material for specific mold components can help prevent a number of costly issues.

Read MoreAngles Stop Negative Areas from Undercutting the Injection Process

The new vertical lifter design provides a range of advantages during mold construction: space savings, easier machining and simplicity of assembly.

Read MoreThink Metric, Part 3

Insight from several technology suppliers—in design software, mold components, programming, machines, cutting tools and measurement equipment who have been following the metric trend—may help to make the transition a smooth one.

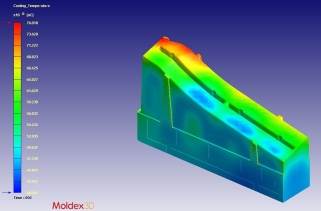

Read MoreDMLS Inserts for Conformal Cooling—Linear Mold & Engineering, Booth 117

conformal cooling lines

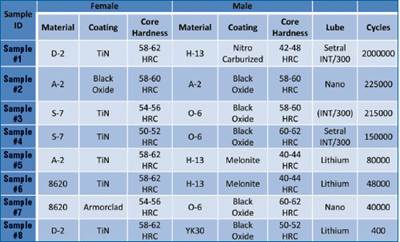

Read MoreTesting Engineered Options for Mold Alignment

Performance data on alignment components helps select the best treatment, improve the design and chart more precise application recommendations.

Read More

.jpg;maxWidth=400;quality=70)