Mold Components

Quick-Change Devices Reduce Setup Time

A line of quick-change devices has been developed that serves as a replacement for traditional nuts and bolts and can reduce setup time.

Read MoreCost of Ownership: A Lifetime of Molding Savings

“There’s nothing more expensive than a cheap mold,” has been said by many a tooling engineer after a bargain of a mold began bleeding profits.

Read MoreDesigning for Downstream

Steps can be taken to deliver to your customer not only a better performing tool, but a better performing tooling investment.

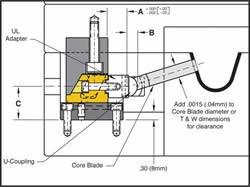

Read MoreImproving Quality and Lowering Mold Component Cost

Ejector and core pins come off the grinding machine with an SPI 4-5 surface finish when using special grinding process technology and proprietary diamond grinding wheels.

Read MoreGain Access to the Recession-Proof Medical Market

Moldmakers who want to diversify into medical—or maintain their competitive edge—need up-to-date, high-tech engineering and fabrication capabilities in order to meet the toolmaking industry’s most stringent quality standards.

Read MoreSteel-Supported, Aluminum Injection Mold Frame Exhibits Durability, Strength

A mold frame that incorporates steel support pillars has all of the thermal benefits of aluminum matched with the durability of a steel mold.

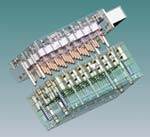

Read MoreIntegrating Hot Runner Mold Construction

Realize time and cost saving benefits from the use of integrated systems when compared to traditional hot runner manufacturing methods

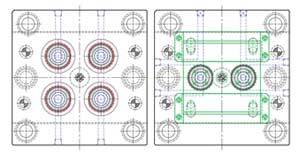

Read MorePlate Positioning Perfected

Consider a positive precision plate device to overcome the risks and uncertainties inherent with springs and spring limiters.

Read MoreA Low-Tech Solution for Cutting Moldmaking Costs

Machine-ready blanks have been available for decades, yet mold manufacturers have been slow to adopt them, even though they can save as much as 30 percent off overall mold and mold component costs and free up machine time for creating more in-house capacity.

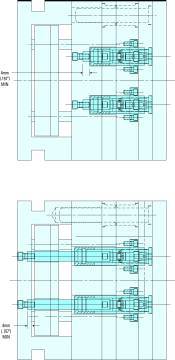

Read MoreRotating Stack Mold Technology Offers Multi-Shot Capability, High-Volume Production

A turning stack mold technology has been developed to meet the rigors of in-mold labeling (IML) production needs that combines high-volume production with multi-shot capability.

Read More