Mold Components

Preform Mold Technology Increases Flexibility, Reduces Cost

A flexible and cost-effective PET system featuring modular, low cavitation PET preform molds reduces both conversion costs and mold changeover time.

Read MoreComplex Molds Mean Business for High-Tech Toolmakers

Focus on cavitation and advanced product design gives progressive mold shops a jump on competitors.

Read MoreUsing TiN Coatings to Protect Your Knock-out/Ejector Pins

Proper surface treatments for enhancing corrosion resistance of mold components in molding situations.

Read MoreSystem Reduces Cure Times and Balances Fill Rates

Two separate technologies work together to first create a homogenous compound temperature exiting the injection molding unit and properly balance the filling of a mold, with the lowest possible cure times while increasing part quality.

Read MoreTandem Mold Technology Trims Production Costs

A process has been developed that uses a mold with two parting levels, which alternately open.

Read MoreDMD Conformal Mold Cooling Lines Offer Reduced Part Production Cycle Times

A conformal mold cooling technology made possible by a new manufacturing technique has been developed to cool molds.

Read MoreA New Approach to Designing Lifter Cores: Dual-Rod Design

Benefits of using a secondary guide rod on lifter core assemblies.

Read MoreIdentifying Common Causes of Failure in Ejector Sleeves

Criteria that can be used in making ejector sleeves, which will minimize or eliminate failures as well as improve the performance and function of ejector sleeves and minimize maintenance.

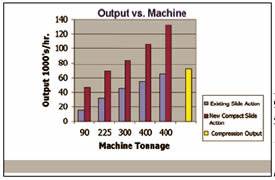

Read MoreSlide Action Technology—Higher Cavitations in Smaller Machines

A new stack mold design—Compact Slide Action Mold Technology (CSAM™)—has been developed to maximize productivity without the need to invest in larger molding machines.

Read MoreHow to Choose the Correct Ejector Pin?

The importance of working temperature during the ejector pin selection process.

Read More