Mold Components

More Standard DT Core Configurations From Roehr Tool Corporation

Roehr Tool Corporation, a pioneer in collapsible core technology, has expanded its line of Dove Tail Collapsible Cores with the addition of new sizes and configurations.

Read MoreCVe Monitor v2 and OnDemand Software Upgraded with More New Features

Monitoring Mold Activity has Never Been Easier

Read MoreInnovative Solutions, Proven Performance at NPE

Progressive Components introduced its Lifetime Guarantee for its patent pending Z-Series Alignment Locks at NPE2015.

Read MoreCommon Sense Innovation and Moldmaker Collaboration

As I walked the aisles of NPE last month, taking in all the plastics-related technologies and solutions on display, two obvious trends emerged: logical innovation and moldmaker collaboration.

Read MoreIn Search of the Infinite Processing Window

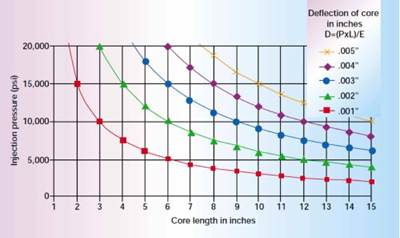

Side-action preload can yield zero core movement during injection and help molders achieve a robust molding process.

Read MoreMolding Very Small Threads and Undercuts Cleanly and Efficiently

New mold component technology helps engineers look differently at how they design small detailed parts.

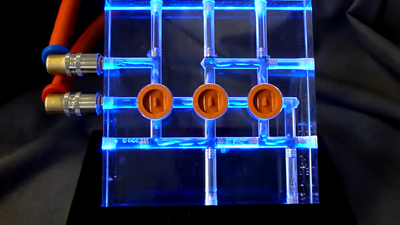

Read MoreWhat's "Cool" at amerimold?

Well, the new CoolCross Z99/ for one, which opens up a range of completely new possibilities for the designer when it comes to designing cooling systems for injection molds. This technology is on display on the show floor in a special setup with plexiglass and water to show the CoolCross live.

Read MoreReaching the Next Level of Efficient Machining

Clamping devices can help to achieve fast and efficient mold plate and cavity/core insert changes during machining.

Read MoreStraight and Simple

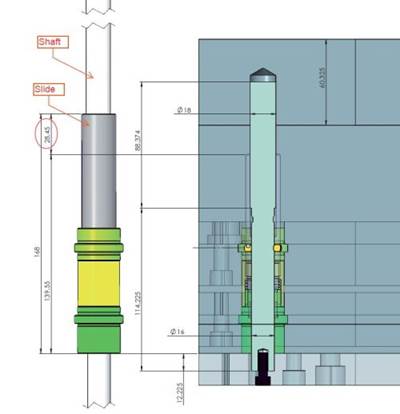

An internal vertical lifter system enabled this shop to design a mold that releases a series of undercuts without requiring angled machining operations.

Read MoreA Supporting Role

This shop solved a critical application problem with help from a distributor in the know about potential solutions and a responsive supplier to help implement them.

Read More