Today's Tools for Tomorrow's Technology Leaders

As you investigate investment in capital equipment, training, services, or a myriad of other technology items, turn to this guide for assistance.

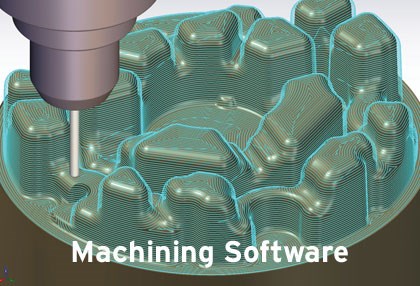

- Machining

- Workholding

- Additive Manufacturing

- Leadership

- Five Axis

- Maintenance & Repair

- Build

- Marketing

- Manage

- EDM

- Maintain

- Business Strategy

- Inspection & Measurement

- Data Management Software

- Automation

- Surface Treatment

- Engineer

- Turning

- Education

- Grinding

- Mold Components

- Mold Materials

- Hot Runners

- Design & Mfg. Software

With business levels continuing to expand—according to MMT’s Economics Editor Bill Wood—moldmakers remain optimistic about future business expectations, while keeping their eyes and ears focused on finding the appropriate technologies in which to invest and the best business strategies to employ, helping to improve their business operations.

And so enters this month’s 2011 Technology Review and Sourcing Guide, which serves as a guide to aide your decision-making process by presenting a year’s worth of technologies and suppliers via a sourcing grid and product reviews—highlighting some of the year’s latest moldmaking product developments within software, rapid prototyping, tooling and manufacturing, materials, hot runner, components, cutting tools, machining, EDM, inspection and measurement, and maintenance, repair and surface treatment.

This year we have included more product releases alongside the supplier grids. This means accurate, comprehensive, easy-to-read and use data on today’s technology, equipment, products and services. The data within this year’s condensed grids appears in its entirety online at moldmakingtechnology.com/suppliers.

The 2011 format includes key supplier profiles preceding a sourcing grid tailored to match suppliers with their respective product/service offerings (advertisers are noted in boldface type), followed by technical product/service reviews.

More than 1,000 manufacturers, distributors and suppliers for more than 200 product and service categories in the following 10 sections are included between our online database and print edition:

1. Software

2. Rapid Prototyping, Tooling & Manufacturing

3. Mold Materials

4. Hot Runners

5. Mold Components

6. Cutting Tools

7. Machining

8. EDM

9. Inspection/Measurement

10. Mold Maintenance, Repair and Surface Treatment

In addition to the listings in this print edition, you can continue your search for even more of the latest in Supplier and Product Information by visiting the various Zones at moldmakingtechnology.com.

We hope you vies this annual guide as a one-stop shop for all of your moldmaking needs—and a vital part of your purchasing process—so please contact us at (800) 579-8809 or via e-mail at cfuges@gardnerweb.com with any comments and/or feedback.

Related Content

-

MMT Chats: Mold Builder Shares “Raw and Real” Social Media Strategy

MoldMaking Technology Editorial Director Christina Fuges sits down with Murphy Forsyth, GM – Injection Molding and Director Of Marketing for Zero Tolerance LLC in Clinton Township, MI.

-

MMT Chats: Simple Steps to Get Your Social Media Campaign Started

MoldMaking Technology Editorial Director Christina Fuges catches up with Gail Now’s Chief Curiosity Officer Gail Robertson. We talk about the importance of using the curiosity tool to tell your stories as part of a marketing strategy that includes social media. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

-

The Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.