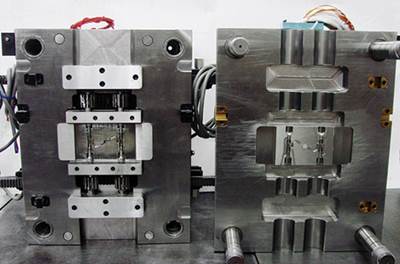

Mold Components

TMA Celebrates Distinguished Members at 90th Annual Meeting

A little over a week ago, I attended the Technology and Manufacturing Association’s Annual Meeting during which awards are bestowed on distinguished members for their work on behalf of the TMA and the manufacturing industry as a whole.

Read MoreSeeing the Industry with a New Perspective

Last week I attended Plastec West in Anaheim, California (what a nice break from frigid temps in Chicago!). It was my first trade show as senior editor of MoldMaking Technology versus attending as a public relations manager for plastics industry suppliers, and I enjoyed seeing everything with a new perspective.

Read MoreA Common Foundation for Speedy Mold Builds

Exacting, interchangeable base plates help this shop start projects quickly and without distractions.

Read More"Rule of Thumb" vs. Engineered Lock Selection

A guide that applies engineering principles is designed to help engineers select properly sized alignment components.

Read MoreThe Economics of Metric

Why pay extra for inches when world economics is moving the U.S. into the metric age. Will this motivate the U.S. to convert in the next two years?

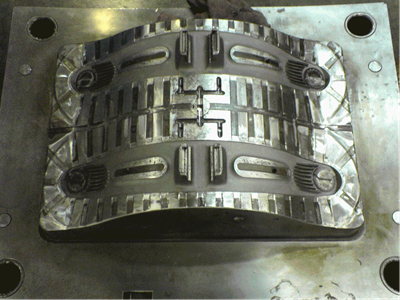

Read MoreThe Designer's Edge: Venting of Mold Components

Venting with mold components, actions and part details is often overlooked as a root cause to allow gases to escape to prevent buildup, erosion and part quality issues. Many will try to process around these issues instead of modifying the tool to address the problem. Here are some recommendations.

Read MoreThe Designer's Edge: More on Venting

Randy shares how his views on venting specs have changed since moving from the tool shop to the molding side of the business.

Read MoreThe Designer's Edge: Venting

Randy shares a real-world perspective on venting and exposes the true value of tool standards.

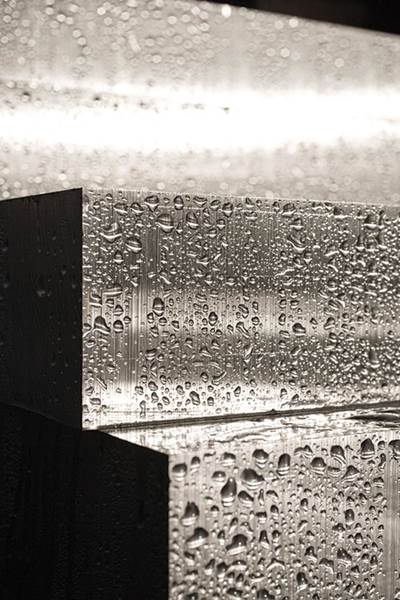

Read MoreMold Water System Basics

Molder to moldmaker: “If you want the project, you need to hit the targeted tooling costs.” Then oftentimes the moldmaker builds a tool that fits the budget, but does not have the best performance with regards to water. Here are some basics about the impact of mold's water system.

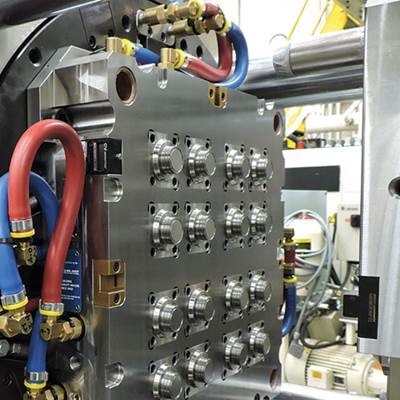

WatchSystem Cooling

The efficiency of the mold cooling circuits are critical to a stable process and the manufacturer of high quality, dimensionally stable parts. Now a new System Cooling platform gives molders the ability to monitor water flow and temperature circuits inside the mold.

Read More