Straight and Simple

An internal vertical lifter system enabled this shop to design a mold that releases a series of undercuts without requiring angled machining operations.

Tony Machado had built his business on situations like this. His shop’s most important customer, Nitto Denko Automotive, had redesigned an important part and decided it could no longer trust an overseas supplier with the corresponding plastic injection mold. As always, Mid Missouri Tool and Die was ready to step up and deliver.

Yet the shop very well could have lost the opportunity to supply the new tool were it not for an internal vertical lifter system that enabled machining entirely with straight-line cuts on its three-axis VMCs. Along with a little in-house ingenuity, these lifters helped the shop win not only the job, but also the opportunity to expand its growing molding operation by running the parts on its own presses.

Growing on the Tough Stuff

Machado’s dealings with Nitto Denko date to his days with a previous employer that shut its doors in 2009. Given the state of the industry at that time, his relationship with the Tier 1 automotive supplier would prove critical when he and his partner, Jim Zade, founded Mid Missouri Tool and Die with three employees in the same year. It remains so today, with Nitto Denko accounting for about 80 percent of the 10,000-square-foot shop's business. “I know you’re not supposed to put all your eggs in one basket, but they have driven our growth,” Machado says.

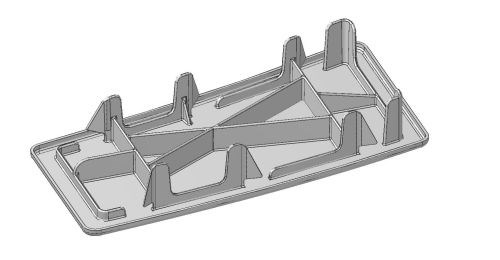

Most of that growth has been driven by “the tough stuff,” Machado says, explaining that he and his 16-person staff often get involved at the design phase to help Nitto engineers turn vision to reality as cost-effectively as possible. In this case, however, the job seemed particularly daunting. The part, a plastic plenum cover that seals off a weld-access hole on Chevy pickup trucks, had been redesigned with triangular connecting tabs that snap into place against the sheet metal to secure the part far better than a previous iteration. Yet Machado and his team immediately recognized that the new tabs would also prove difficult to release from the mold. Further complicating things was the fact that the customer was eager to start production as quickly as possible.

Given the part’s function, putting a hole in the surface for core access would defeat the purpose. Likewise, the action of conventional external sliding mechanisms would shear off the rib that keeps sealing compound within a channel around the part's periphery. Lifters would work, but they’d have to traverse at a 17.5-degree angle to release the undercuts. Without a wire EDM or five-axis machining center, cutting angled pockets to facilitate this motion through the mold insert and cavity plate would be a tall order for the Carollton, Mo. shop.

An Easier Approach

The team was brainstorming possible production scenarios when “it just clicked,” Machado says. He’d already seen a potential solution some time ago in a catalog from Cumsa, a Spanish manufacturer of mold components. After consultations with designers at Cumsa USA in Michigan, the shop took delivery of 48 of the company’s DH series vertical lifters to split evenly between two identical, four-cavity molds.

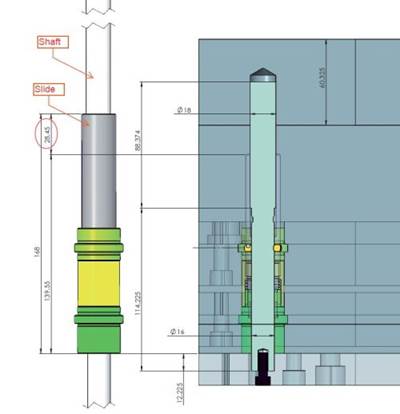

In contrast to models with angled rods and various connections and joints, the DH series offers a relatively simple design, and the motion is almost entirely vertical. As seen in the picture on the right, the lifters employ two steel, right-triangle blocks (base and slide) that mate together to form a rectangle via dovetail-style T-slot connections along the hypotenuse of each. Motion is actuated by a rod that mounts to an ejector plate through a straight, vertical channel in the mold. When the ejector plate moves forward, the rod engages with the slide (the triangular block containing the undercut detail) to push it upward and outward at an angle—in the case of this application, 17.5 degrees.

This configuration is intended to simplify both engineering and machining, and Machado reports that was certainly the case for this job. With all angled movement confined within the lifter’s own vertical space, the shop had no need to manipulate the entire tool design to accommodate slanting channels. Likewise, drilling and counterboring a channel through the support and ejector plates was preferable to cutting the long slots that would be required to accommodate the motion of an angled actuating rod. Most importantly, the shop could machine the insert and cavity plate pockets with basic setups on its three-axis Hurco VMCs rather than using a sine plate, outsourcing the work, or investing in a wire EDM or five-axis machining center.

Beyond Lifters

However, the shop soon discovered that even without the angle, machining those pockets without wire EDM wasn’t such a simple proposition. Given the shape of the lifters, the pockets require square corners to ensure a snug fit within the tool. However, such geometry is impossible to produce with the edge of a round end mill, which naturally leaves a slight radius in the material when turning at right angles.

The solution was to fit each lifter into what is essentially a pocket within a pocket. The outer pocket, machined directly into the tool, has rounded edges and is slightly oversized to leave 0.375 inch of space on all four sides of the lifter. That space is filled by two U-shaped pieces of steel inserted end-to-end to form the square-cornered inner pocket.

Each piece required two VMC setups. First, the corner radii on one end were machined to match the rounded pocket in the tool. Then, a pass across the entire width of the part created a flat, squared surface on the other end. For the second setup, the workpiece was mounted flat-side-up for straight-line passes that removed a chunk of material from the center to form the square-cornered interior of the U shape. “You can cut a 90-degree angle as long as you’re using the tip of the cutter and not the edge of the cutter,” Machado explains.

Yet the lifters alone wouldn’t be enough. Moving them forward 0.75 inch would be sufficient to release the undercuts, but not to push the part out of the cavity. To provide the necessary two-stage motion, each of the two molds incorporates two DX series double-ejector rods from Cumsa. Via a telescope-like action in which a hollow outer sleeve slides along an inner shaft, these components actuate two separate ejector plates: a rear plate that anchors the lifters and moves just far enough forward to release the undercuts before stopping, and a front plate with standard ejector pins that continues through the full stroke to eject the part. Machado credits Cumsa engineer Jorge de Fortuny for helping make the modifications needed to incorporate these components within the tool (click here for more information).

Long-Term Advantages

Although the toolmaking portion of the job is long finished, the shop continues to reap the benefits of the molds’ simplified design. As is the case for many other Nitto Denko parts, it runs the tools in its own four in-house presses, and the lifter design helps ease maintenance, Machado says. Unlike angled models with various wear points inside the tool, the only component of the DH lifters subject to wear is the sliding portion. Given that this is easily accessible at the top of the cavity plate, operators can keep the component lubricated in between scheduled preventive maintenance cycles. He adds that the two sliding portions are constructed of dissimilar metals to limit friction. “We’ve run 100,000 cycles so far on each of the two tools, and everything still looks brand new,” he says. Of course, he emphasizes that the most important benefit of the lifters was getting the job in the first place.

Related Content

Making Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.

Read MoreHow to Solve Hot Runner Challenges When Molding with Bioresins

A review of the considerations and adaptations required to design hot runners and implement highly productive injection molding operations.

Read MoreConfronting the Mold Design Talent Drought

Recently, I reposted on LinkedIn the results of an informal survey we conducted, which revealed a shortage of skilled mold designers. It quickly gained a lot of traction. Given the response, I thought I'd summarize the feedback and keep the conversation going.

Read MoreMaking Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

Read MoreRead Next

A Supporting Role

This shop solved a critical application problem with help from a distributor in the know about potential solutions and a responsive supplier to help implement them.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More