Mold Components

Throwback Thursday: Run Clean, Run Efficient

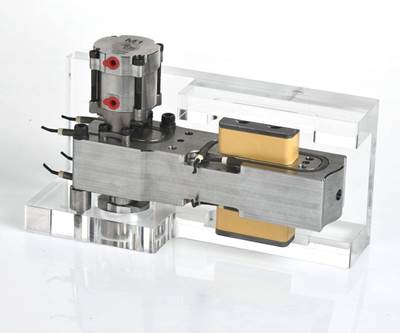

If you or your customer is concerned with achieving faster cycle times (and who isn't?) plus cleanroom-caliber mold function and lower maintenance, here's a throwback case study about better undercut release for small medical, or similar, parts using expandable cavities.

Read MoreTechnology Tuesday: Hot Runners and Mold Components

This week’s Tech Tuesday blog brings readers a review of several products announced during the last few weeks, namely hot runner and mold componentry.

Read MoreGet More Coolant Flow Through Smaller Bubblers

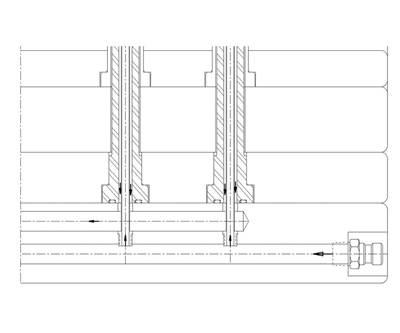

This method for calculating the size of nonround water passages is designed to increase coolant flow, and reduce pressure loss and cycle time.

Read MoreMilacron's DME Announces Partnership with Linear AMS for Conformal Cooling Solution

Milacron’s DME Product Brand Announces Partnership with 3D Additive Leader Linear AMS to Provide Revolutionary Conformal Cooling Solutions under its New TruCool® Product Line

Read MoreThink Global: Go Metric

This throwback Thursday article makes the case for why the United States should adopt the metric system as its global standard.

Read MoreSlideshow, Technology Showcase: Molds and Molding

Last month I was able to escape a nasty winter storm by heading to the warm west coast where many mold builders, molders and technology suppliers set up shop to show off their capabilities.

Read MoreIn Memory of Donald Starkey Sr., D&L/Progressive Components

It is with a sad heart that I submit this blog. The industry has lost yet another gem of a person in Don Starkey Sr.

Read MoreSLIDESHOW: Technology Showcase, MMT Surprise

This week's slideshow is an MMT 'Surprise' Showcase, editor’s picks for the week.

Read MoreThrowback Thursday: Improving Ejector Plate Alignment

Some concepts are worth a second look like this new alignment system that is said to be able to provide a more reliable mold by reducing wear on the moving ejector components.

Read MoreCaring for Hydraulic Cylinders

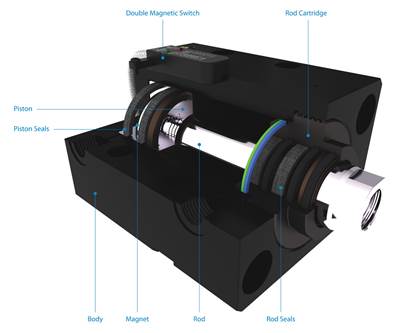

Preventive maintenance on these important components will help keep a mold running.

Read More