Throwback Thursday: Improving Ejector Plate Alignment

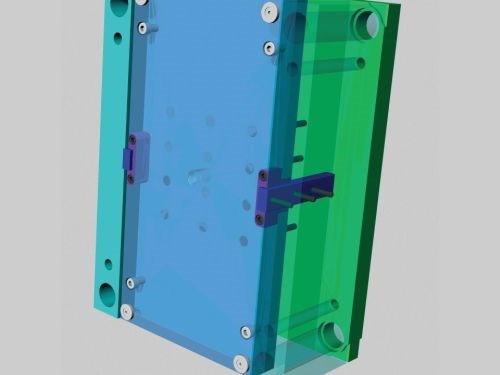

Some concepts are worth a second look like this new alignment system that is said to be able to provide a more reliable mold by reducing wear on the moving ejector components.

An alignment bar and wear pad make up this ejector plate alignment system. The wear pad is a precise one-piece design that accurately fits with the alignment bar. The design’s simplicity also accounts for the machining of the components and the mold base plates, easing their manufacture while still providing optimum support.

The pockets in the plates are also designed to be machined in the same setup as the counter bore for ejector pins and additional screws. The alignment bars are on the center line of the mold base, minimizing the effect of thermal expansion. With larger molds the weight of multiple ejector plates is no longer an issue.

According to Dave Frost of Frost Techincal Concepts, all of this provides precise alignment and a more reliable mold by reducing wear on the moving ejector components. It also provides more useable space in the mold base.

Click here to read the entire article.

Related Content

-

Machine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

-

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.