Think Global: Go Metric

This throwback Thursday article makes the case for why the United States should adopt the metric system as its global standard.

One man builds an argument for designing and building in metric, Part 1.

The other day I was working on an article about a mold designer who works for a mold components supplier. Her company is well known and global, so she has to think in both inch and metric sizes when she’s providing guidance on mold designs and hot runner systems. It’s all dependent on whether the customer is based in the U.S. or somewhere else in the world. Why doesn’t the U.S. adapt to metric standards?

There are many arguments for and against the U.S. going metric. I remember as a young student having to learn about metric because at the time, the government was trying to move in that direction. But something blocked that momentum and metric went away.

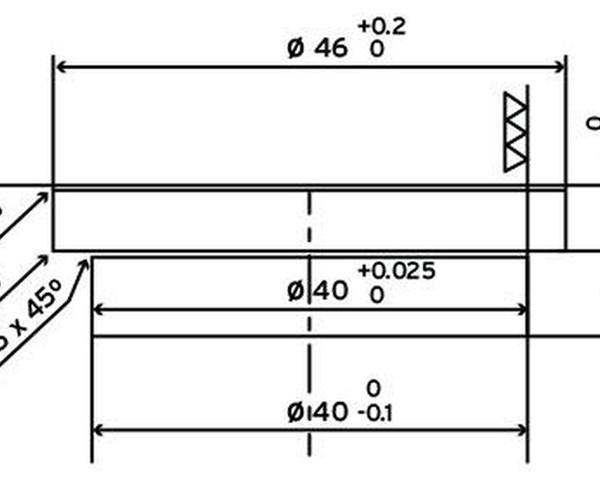

Well, for today’s throwback Thursday article, I found one man’s article in which he makes a case for metric. He lists a few very good reasons for going metric: The rest of the world (except Burma and Liberia) uses metric; it can help win jobs from EU companies; metric components, by and large, are less expensive. There are more reasons, but I’ll let you read for yourselves, MMT fans.

Please click here to access Part 1 of “Think Metric,” from MMT’s March 2013 issue.

Related Content

-

The Secrets to Hard Milling Success

The Secrets to Hard Milling Success

-

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

-

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.