Build

DLC-Coated Latch Locks from Meusburger Improve Service Life, Cleanroom Suitability

Meusburger, an Amerimold 2021 exhibitor, improves the capabilities of its flat and round latch locks with DLC-coated switching elements.

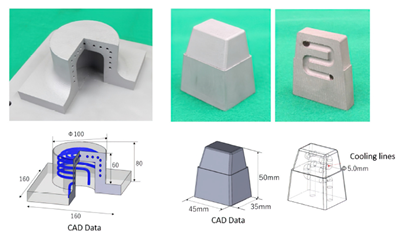

Read More3D Printing Speeds Prototyping and Shifts Talent to Production Tooling

A digital approach to prototyping using 3D-printed tooling accelerates product development and frees up mold builders for production tooling work.

Read MoreEuroheater USA Releases Modular Hot Runner Temperature Controllers

Temperature controllers from Amerimold 2021 exhibitor Euroheaters USA detect channel temperature via an intelligent chip for a constant, desired temperature.

Read MoreCUMSA Introduces Remote Date Stamp System for Enhanced Traceability

Amerimold 2021 exhibitor CUMSA showcases its remote date stamp system which enables users to change date information in the mold easier, faster and more accurately.

Read MoreDME Brings EZ Latch Locks, Servomold and S-Core to Amerimold

DME’s EZ latch locks, Servomold unscrewing devices and new S-Core collapsible cores offer multiple configurations and promise longevity, flexibility and ease of use for moldmakers.

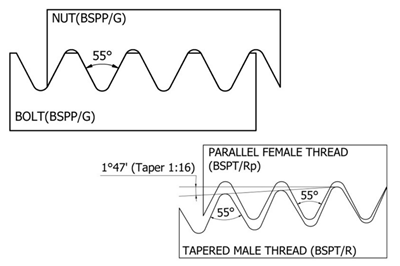

Read MoreHow to Machine and Seal Metric Cooling Line Threads

Understanding the machining of British standard pipe parallel (BSPP) and British standard pipe taper (BSPT) straight threads helps identify why a cooling plug may not be sealing correctly.

Read MoreEmuge-Franken USA Partners With Grob Systems to Develop Turnkey Five-Axis Solutions

At Emuge-Franken’s technology center, manufacturers with demanding five-axis mill-turn applications can optimize their parts and components on the Grob 350T together with the full line of Emuge-Franken cutting tool solutions.

Read MoreExploring AM Powders for Tooling

More options in AM tooling materials exist today that provide properties for crack resistance, thermal conductivity and heat treatment.

Read MoreSwiss Steel Highlights Specialty Steel Material for High Corrosion Resistance

Amerimold 2021 exhibitor Swiss Steel offers Corroplast, a stainless steel mold base material for use in high-humidity environments and with corrosive resins.

Read MoreWEBINAR: Tool Steel Demands and Enhancements

Pressurized electro-slag refining and powder metal production techniques remove impurities when producing highly alloyed stainless steel grades specifically for moldmaking. Listen to this free webinar to learn about current trends in the plastics industry, next-generation stainless tool steels, production techniques and additively manufactured parts and components.

Read More