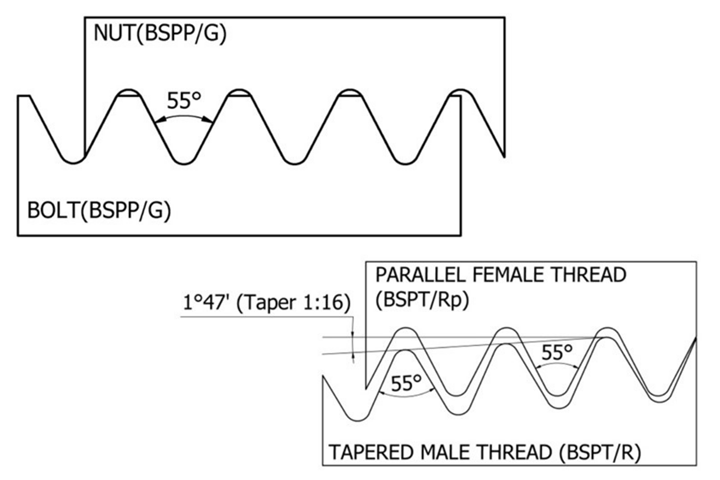

BSPP (G) male and female parallel thread ID/OD (Fig. 1, top left), BSPT (R) male taper thread OD/female parallel thread ID (Fig. 2, bottom right). All photo credit: Hasco America Inc.

A common challenge for North American mold designers and mold builders is finding good information on how to seal a metric straight cooling plug or fitting. In North America, shops more widely use national pipe thread (NPT) fitting threads, so they are less familiar with British standard pipe parallel (BSPP) straight thread pipe plug use. Here we will focus on metric thread fittings for pipe threads (G-thread or BSPP and R-thread or BSPT), and the fitting and sealing specifically.

Machining Tips

The most critical aspect of machining for straight-type cooling plugs and fittings is the cooling line core diameter, which should never exceed the minimum thread core ID. Adhering to this rule while also using threading compound (e.g., pipe tape) allows the plug or fitting to seal. Some cooling line plugs include a copper sealing washer or a recommendation to use an o-ring for positive sealing.

Each pipe designation identifies a fuel type, not a thread classification. For example, the “F” in NPTF is for fuel. NPTF threads generally do not require additional Teflon tape or sealant. They seal off with the tapered thread. The “G” in BSPP and the “R” in BSPT refer to gas parallel and gas taper, and both require additional sealing tape or application of a sealant to seal off.

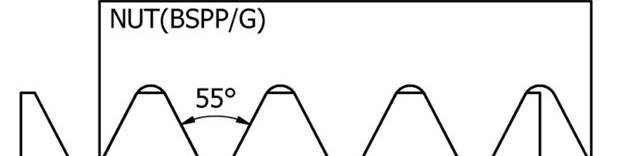

NPT and BSPP threads are not compatible. The NPT thread has a 60-degree angle with flattened peaks and valleys. A BSP thread has a 55-degree angle with rounded peaks and valleys. You should never mate a BSP thread and an NPT thread, as the incompatibility prevents reaching the required pressure ratings and will damage threads.

Pay special attention to the fitting type you are using on the cooling line.

A BSPP thread is parallel on the male fitting and female thread in the cooling line (G). A BSPT thread is tapered on the male fitting (R) and the female thread in the cooling line is either tapered or parallel. This means you can machine the ID or a female thread tapered or parallel on the cooling lines for (R) only.

Pay special attention to the fitting type you are using on the cooling line. For example, (G) BSPP male fittings can only be screwed into the female parallel (G) threads, but (R) BSPT male fittings can be screwed into the female parallel (G) and female tapered (R) threads.

Measurement Tips

After selecting your thread type for the fitting and cooling lines, calculate the minor cooling line and tap drill diameters. These two measurements ensure that you successfully assemble the cooling line plug or fitting to seal off. If the main cooling line is larger than the minor cooling line and tap drill diameters, you will not achieve seal off no matter how much sealing tape you add. Take caution when drilling the cooling lines—even before machining the female thread—so enough steel remains for the entire thread detail.

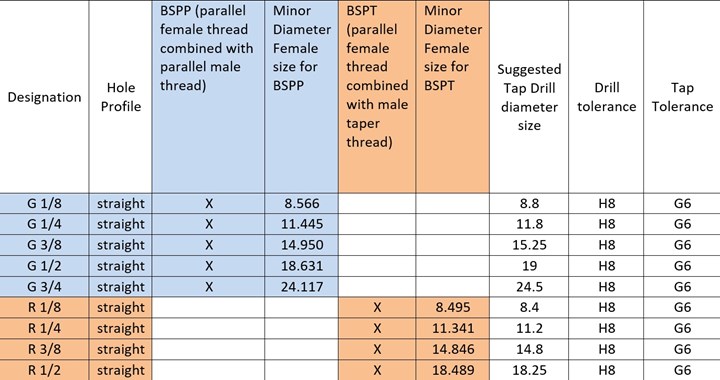

For example, when using a fitting with a G1/4 thread designation, use a cooling line with a drilled hole at 10 to 11 millimeters (0.394 to 0.433 inch) in diameter. The thread minor straight diameter is 11.445 millimeters and the tap drill diameter is 11.8 millimeters, yielding enough steel for the cooling line so you can work in the required thread.

Another example is when using a fitting with an R1/4 thread designation, use a cooling line with a drilled hole at 10 to 11 millimeters (0.394 to 0.433 inch) in diameter. The thread minor straight diameter is 11.341 millimeters and the tap drill diameter is 11.2 millimeters (see Chart 1 and Figures 1 and 2 for reference.)

Chart 1. BSPP and BSPT parallel thread minor cooling line and tap drill diameters.

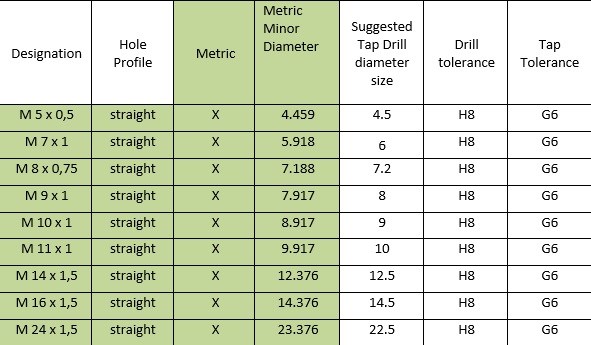

This same principle applies to the metric M thread designations. Metric ISO fine threads use a 60-degree included angle with a parallel thread. The male fitting and female threads in the cooling lines are both parallel. For example, when using a fitting with a M5 x 0.5 thread designation, use a cooling line with a drilled hole at 3 or 4 millimeters (0.118 to 0.157 inch) in diameter. The thread minor straight diameter is 4.459 millimeters, and the tap drill diameter is 4.5 millimeters (see Chart 2).

Chart 2. M or Metric parallel thread minor cooling line and tap drill diameters.

Once you apply the correct drill and tap size and tolerance, following these tips for using straight female-threaded cooling lines is easy. To seal the fitting completely, make sure you add enough sealant tape or sealing medium. As with any straight threads, the plugs will keep going deeper into the threaded holes unless it is a style with a collar and a copper sealing washer. Pressure testing of cooling line systems is recommended before production to eliminate any possible production line leak issues.

Following these steps will increase your chances of success in properly sealing these fitting types.

Related Content

Surface Finish: Understanding Mold Surface Lingo

The correlation between the units of measure used to define mold surfaces is a commonly raised question. This article will lay these units of measure side by side in a conversion format so that companies can confidently understand with what they are dealing.

Read MoreWhat You Should Consider When Purchasing Modified P20 Steel

When buying P20 steels that have been modified, moldmakers must be aware of the variations and key issues that affect delivery, cost and lead times.

Read MoreLine Width vs. Depth Ratio in Laser Engraving

A laser does not produce 90-degree sidewalls. It requires a certain amount of draft in order to produce the required pattern.

Read MoreHow to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreRead Next

Webinar: Standard Components – Options that Simplify Mold Designs, Reduce Costs and Speed Mold Building

October 23 webinar will discuss new options and advantages of using standardized components.

Read MoreThe Economics of Metric

Why pay extra for inches when world economics is moving the U.S. into the metric age. Will this motivate the U.S. to convert in the next two years?

Read MoreHow Latch Locks Speed Mold Build Time

Ten key features and functions of internal and side-mounting latch-lock devices that help moldmakers build molds faster and more safely.

Read More

.jpg;maxWidth=300;quality=90)