DLC-Coated Latch Locks from Meusburger Improve Service Life, Cleanroom Suitability

Meusburger, an Amerimold 2021 exhibitor, improves the capabilities of its flat and round latch locks with DLC-coated switching elements.

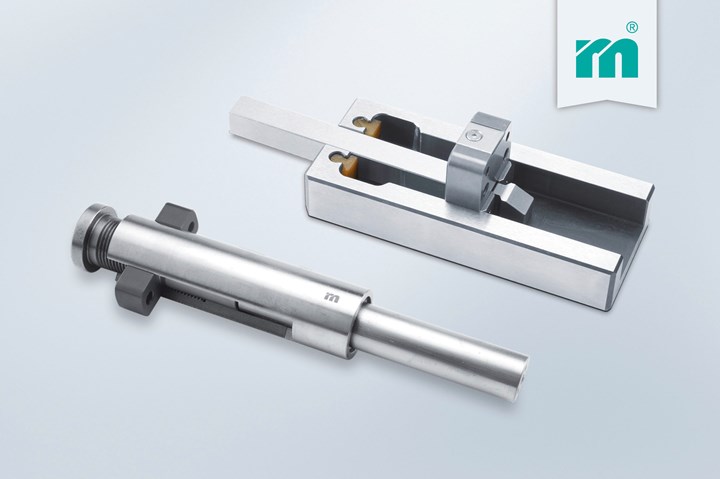

Tried and trusted latch locks. Photo Credit: Meusburger US Inc.

The switching elements of the Meusburger E 1820 flat latch lock and E 1840 round latch lock now come with a DLC coating for even longer service life and, due to excellent dry-running properties, suitability for use in cleanrooms.

The high-quality latch locks are used to control and securely lock the floating plate in three-plate molds. According to Meusburger, the compact E 1820 flat latch lock ensures optimal force transmission through its stable, large surface latches. Further, DLC-coated switching elements give these flat latch locks even longer service life. Precise control cams ensure accurate switching while the integrated damper provides for a smooth and quiet operation.

The Meusburger E 1840 round latch lock is said to be an optimal solution for mold bases where no protruding attachments are allowed. Meusburger says installation space required for the round latch lock can be easily created through unidirectional machining. Because of the DLC-coated switching elements and catch part, the round latch lock can now also be used in cleanrooms, and reduces overall wear.

To view this latch lock selection online, customers can enter required parameters and export the ready-to-use latch locks to their CAD software. Both products are immediately available from stock.

Exhibitor: Meusburger US Inc.

Booth 224 (P)

Related Content

-

Where Mold Manufacturing and Plastics Processing Connect

The Moldmaking Pavilion is one of seven pavilions returning to the show that houses exhibitors offering technology and service solutions for your specific moldmaking needs.

-

MoldMaking Technology's Leadtime Leader Awards Competition Returns!

After a brief hiatus, MoldMaking Technology’s Leadtime Leader Awards Competition is back!

-

More Than Moldmaking at PTXPO 2023

The Moldmaking Pavilion returns to the Plastics Technology Expo (PTXPO) March 28-30, 2023, at the Donald E. Stephens Convention Center in Rosemont, Illinois, but there’s more to discover than moldmaking.