Build

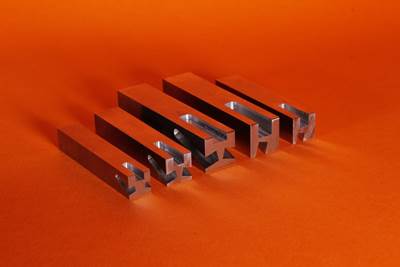

Edge Gate Cutting Pin Range Forms to Molding Edge Profile

Almo introduces its flexible edge gate cutting pins for the separation of the runner and gate on the edge of the plastic molding during mold opening.

Read MoreThe Benefits of Alloying Tool Steel

Improve tooling efficiencies, extend mold life and reduce overall tooling costs with a focus on tool steel properties that solve wear, flaking and cracking issues.

Read MoreCollapsible Cores Optimize Molding Threads and Undercuts

DME’s S-Core Collapsible Cores enable parts production from six to 400 mm and three different segment designs.

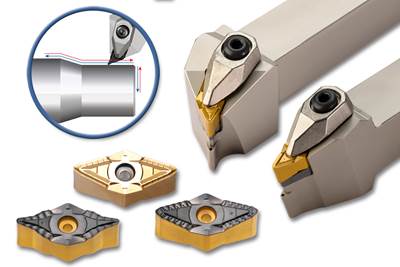

WatchMulti-Directional Turning Tool Maximizes Materials Removal

The SuperTurnZ from Ingersoll Cutting Tools utilizes the front and back cutting edge of a four-corner insert in a single tool for higher feed rate capabilities.

Read MoreFive-Axis Machining Center Processes Smaller Workpieces

Mitsui Seiki’s PJ 303X five-axis machining center features a 50,000-rpm, HSK-E25 taper spindle, which offers high-speed machining capability, as well as an automatic tool changer that can store up to 24 tools.

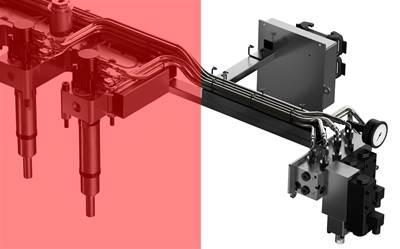

Read MoreMechanical Stroke Regulator for Hot Runner Systems

Oerlikon HRSflow’s mechanical stroke regulator (MSR) for hydraulic driven valve gate systems allows for easy pin adjustment even with hydraulic actuation.

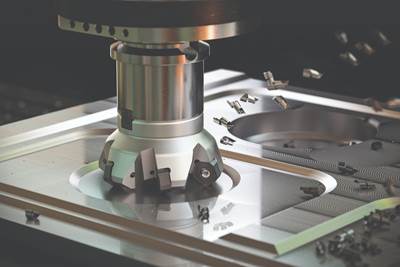

Read MoreFace Milling Platform Combines Multi-Corner Milling, High Feed Rates

YG-1’s FM10 PNMU inserts are designed to separate the cutting edge and the wiper, which results in ten true cutting edges.

Read MoreFlanged, Pneumatically Operated Needle Valve Unit Highlights Enclosed, Simple Mounting System

The H107940 drive units by Hasco can be mounted directly on a hot runner via a flange construction and is used primarily for fully wired and piped systems.

Read MoreMechanical Cycle Counters for High-Temperature Applications

Hasco reveals cycle counters A5730HT and A57300HT for process data monitoring up to 200°C and assembly flexibility.

Read MoreMMT Chats: 5 in 5 with X-Cell Tool and Mold

MoldMaking Technology Editorial Director Christina Fuges has a quick 5-minute chat with Brian Dippel, the Operations Manager for X-Cell Tool and Mold in Fairview, Pennsylvania and MMT’s 2019 Leadtime Leader Winner. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Watch