Build

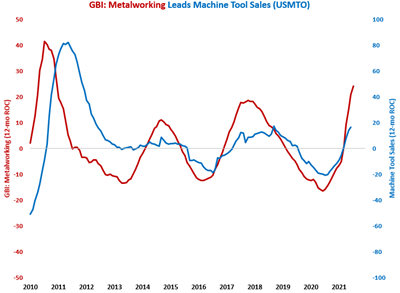

Unit Machine Tool Orders Highest Since October 2018

The GBI: Metalworking is growing at its fastest rate since December 2010. The rapid growth in the metalworking industry should lead to accelerating growth in machine tool orders throughout 2021.

Read MoreMold-Masters Accu-Valve Extends Valve Gate Quality and Reliability

The Accu-Valve family, to be featured at Amerimold, attributes continuous 360-degree pin guidance for high tolerance dimensions and concentricity, reducing maintenance and extending service life.

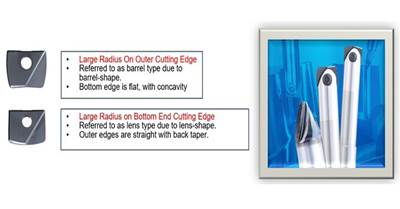

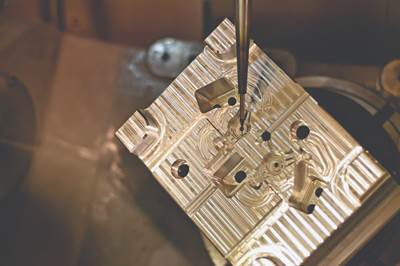

Read MoreWhy Mold Builders Should Consider Barrel Cutters and Lens Tools If They Haven’t Before

Reduce machining cycle times and improve surface finishes of cavity and core work with barrel cutters and lens tools.

Read MoreOerlikon HRSflow Introduces S Series Line with Reduced Nozzle Pitch Size

Hot runner line’s compact design reduces nozzle pitch, plate thickness and offers more rapid color changes for the production of small technical parts.

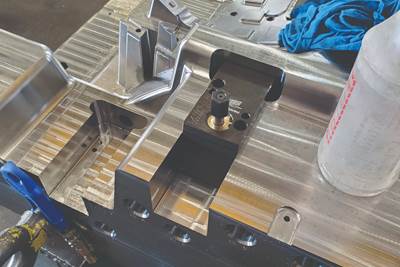

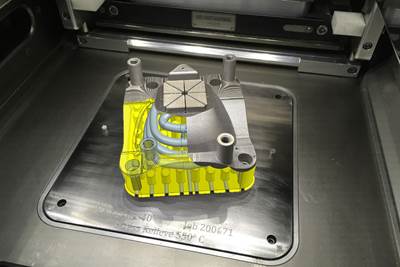

Read MoreHybrid Approach to Producing Mold Inserts Boosts Productivity and Profitability

Mold inserts with additively produced cooling circuits eliminate design constraints, reduce the cost of complexity, improve part dimensions, decrease cycle time and speed time to market.

Read MorePCP Aluminium Promotes Aluminum Cast Plate/Block For High-Quality Performance

PCP Aluminium will presents ACLA5 and MAX5 Aluminum to Amerimold exhibitors, suitable for prototype injection, thermoforming molds and mold automation systems.

Read More2021 Sourcing & Technology Guide: Mold Materials

Proper selection of the appropriate mold material is critical to manufacturing a high-quality mold. Tool steel, aluminum, copper and alloys are some of the materials used.

Read More2021 Sourcing & Technology Guide: Mold Components

Mold components make the mold work and the mechanisms used to deliver a quality end product. Key components include mold bases, pins, ejectors, lifters, bushings, guides and alignment devices.

Read More2021 Sourcing & Technology Guide: Additive Manufacturing

3D printing, or additive manufacturing, simplifies the moldmaking process by making mold inserts, mold components, end-use parts and ancillary equipment.

Read MoreErowa Technology to Preview PowerChuck P to Amerimold Attendees

The new system offers users a more flexible and precise interface between machine and workpiece, with 10,000 N clamping force, a compact design and complete automation.

Read More