Swiss Steel Highlights Specialty Steel Material for High Corrosion Resistance

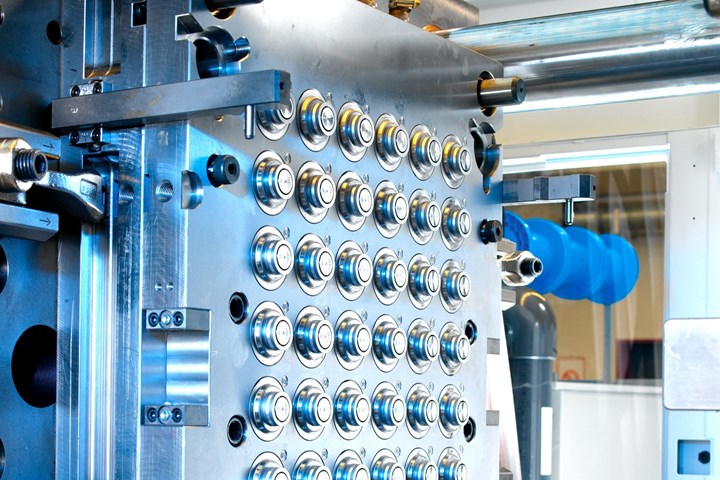

Amerimold 2021 exhibitor Swiss Steel offers Corroplast, a stainless steel mold base material for use in high-humidity environments and with corrosive resins.

Photo Credit: Swiss Steel Group

Swiss Steel Group says it is continually developing specialty steels to combat highly corrosive injection molding environments, while also improving mold steel machinability and dimensional stability. The company offers Corroplast, its free-machining stainless steel mold base material as an example. The pre-hardened steel combines a special chemical composition with a special heat-treatment process, and is said to be an ideal material to resist corrosion associated with high-humidity environments and when corrosive resins are used in production.

Corroplast also exhibits reduced carbon for improved weldability, and is characterized by low internal stress. It can also be used for mold inserts, provided that standard demands on the engraved surface are applied.

Swiss Steel will be available to discuss technical challenges regarding mold steel selection and proper heat treatment solutions at Amerimold 2021.

Exhibitor: Swiss Steel USA Inc.

Booth 310

Related Content

-

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

-

What You Should Consider When Purchasing Modified P20 Steel

When buying P20 steels that have been modified, moldmakers must be aware of the variations and key issues that affect delivery, cost and lead times.

-

VIDEO: Qualifying Modified H-13 for 3D-Printed Tooling

Next Chapter Manufacturing and International Mold Steel discuss their partnership to qualify a modified H-13 for tooling applications.