Build

July Points to Another Strong Month for Machine Tool Orders

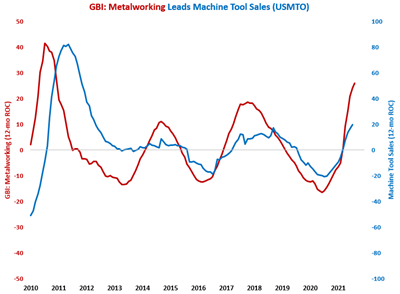

Compared with one year ago, the GBI: Metalworking was 23.5% higher, which was the 13th consecutive month of growth. The strong growth in the metalworking industry should lead to accelerating growth in machine tool orders throughout 2021.

Read MoreThree Keys to Managing a Successful Tool Transfer

How to effectively manage a tool transfer despite rundown tools, an outdated automation system and difficult materials.

Read MoreTungsten Carbide Core Pins Reduce Core Shift and Deflection

According to the Craft Technology, CraftAlloy tooling is more rigid than other mold tooling materials on the market; it reduces core shift and deflection, which reportedly enables the highest possible process capability with injection molded parts.

Read MoreEnvisionTEC, Covestro Develop Industrial 3D Printing Solution for Rapid Injection Mold Tooling Production

Covestro DLP resin e-PerFORM used with EnvisionTEC’s Perfactory P4K series DLP 3D printing demonstrates faster, more cost-effective print speeds with high stiffness, high temperature performance.

Read MoreHow to Use Hybrid Additive Manufacturing

A look at directed energy deposition (DED) and powder bed fusion (PBF) additive technologies for moldmaking applications.

WatchCooled Ante-Chamber Bush Gate Regulates Gate Point Temperature Control

Meusburger’s cooled ante-chamber bush EC with customizable gate diameters features cooling close to the gate point along the entire circumference of the hot runner nozzle.

Read MoreHurco North America Launches New Apprenticeship Program

Hurco’s Field Service Apprenticeship (FSA) is a two-year program that starts with a 12-week industry training which merges hands-on training and repair of CNC machines with classroom materials.

WatchHusky Introduces UltraShot Hot Runner Injection Molding System

Amerimold exhibitor features the advanced technology which permits more precise melt control and the ability to produce identical, repeatable performance in every cavity.

Read MoreWestminster Tool Awarded $100,000 Grant for Additive Technology

Westminster Tool joins six manufacturing companies in CT as recipients of the latest Additive Manufacturing Adoption Program (AMAP) grant, highlights its importance to injection moldmaking.

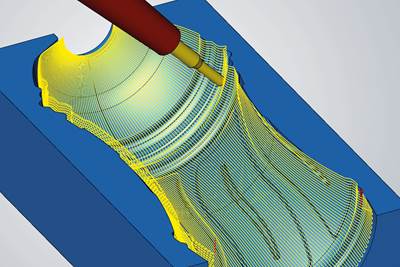

Read MoreCAM Software Optimizes Blow Mold Manufacturing

The hyperMILL software suite from OPEN MIND Technologies meets demanding blow mold requirements with automation processes, data import, efficient programming and NC code simulation.

Watch