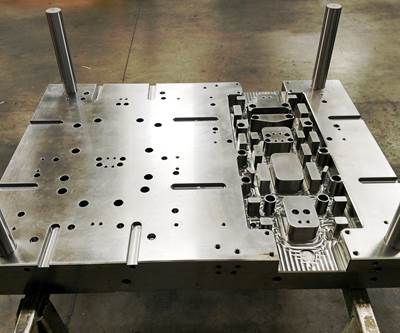

Internal view of insert with conformal cooling printed in DAP-AM HTC40 powder. All photo credit: International Mold Steel.

Additive manufacturing (AM) has been making its way into more tooling applications and the importance of conformal cooling in molds and dies has moved from the novelty stage to accepted practice. Following those trends, global specialty steel producers are making significant investments in AM, yielding new materials that combine ease of printability with physical properties focused on tooling requirements.

Although maraging steel has been the material of choice, there are now more options in AM tooling materials that offer solutions for common crack resistance, thermal conductivity and heat treatment challenges. These new materials enable mold builders and molders to add conformal cooling and take advantage of physical properties that make more consistent plastic parts, reduce lead times and simplify the moldmaking process.

Understand AM's Benefits to the Mold and Molding Process

Plastic injection molding is a highly competitive business. Molds must be produced as quickly and cost-effectively as possible. Reducing lead times is where AM shines. Here are a few AM basics to understand before your AM material decision-making begins.

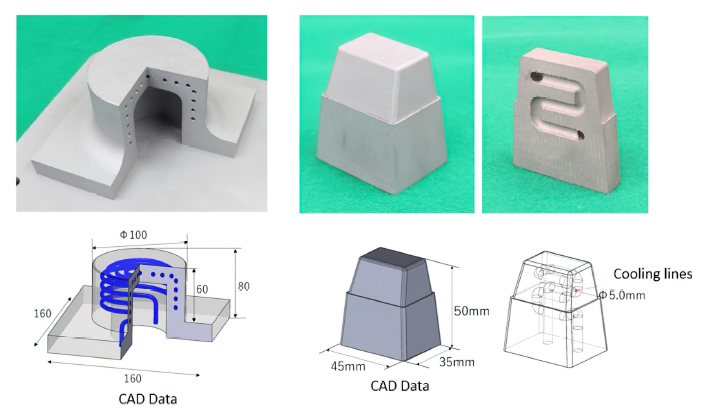

First, molds produced via AM are generally completed in weeks rather than months. Printing molds involves CAD files that can be quickly transferred between the mold user and the moldmaker; changes can happen in hours and printing the parts (depending on size) can take several days. However, new, more powerful printers are printing faster and reducing these print times. These new printers are increasing the size of parts available for printing from about 12 cubic inches (290 millimeters) to 16-18 cubic inches (400-500 millimeters), to 1,000 cubic millimeters.

Newer AM tooling materials also have simpler heat treat cycles, reducing lead times and streamlining mold production. However, it is important to calculate the costs on a value basis, which means the cost of the printed mold must include its reduced cycle time, improved mold life and decreased mold inventory benefits.

The green aspect of AM is also often overlooked. Unlike subtractive manufacturing, AM does not produce a large percentage of scrap from the moldmaking process. Shops can lightweight molds by adding material only where it is required. This design freedom encourages engineers to think in a new way.

It is not just the properties of the materials but also the characteristics of the powder—chemical composition, particle size distribution, particle shape, particle flowability and particle density—which is part of the AM inspection certificate that accompanies the AM powder.

Determine Mold Quality

It’s essential to identify what makes a quality plastic injection mold to better understand the value of AM to the mold manufacturing process and select the suitable AM material to use for your mold build.

Here are two critical factors for determining the quality of a plastic injection mold and how AM fits into the mold build process to help meet and exceed these quality standards:

1. The mold's ability to quickly and consistently produce quality parts in conjunction with conformal cooling.

AM involves designing conformal cooling channels, unlike anything that a shop can produce with subtractive machining. Using AM, a mold builder can design conformal cooling channels that hug the contour of the part surface, eliminating hot and cool spots in the parts and reducing the risk of distortion. On top of that, using computer simulation software simplifies identifying the proper location for the cooling lines.

Removing the heat from the mold as quickly as possible is the key to reducing the amount of time the part must remain in the mold. Cooling line placement is one part of the equation. The other part is the steel’s ability to cool the mold, also known as thermal conductivity. Several mold material producers offer materials with high thermal conductivity (HTC).

2. The mold's strength and toughness at elevated temperatures.

This determines how long the mold will be able to run before downtime for maintenance is necessary. Strength goes together with hardness, which is determined primarily by the carbon content. However, high carbon content is where printability becomes an issue because higher carbon content can lead to cracking, reducing mold life.

DAP-AM HTC40 powder containers.

AM is a combination of melting and heat treating that is impossible in traditional wrought operations. For example, laser powder bed fusion (L-PBF) is an AM process for building molds. It is a series of layer-by-layer melting of powder via a laser with subsequent gas cooling. Phase transformation occurs in this cooling, which, if not controlled, can lead to cracking.

However, today there are newly developed AM materials designed to reduce the carbon content, which prevents cracking but maintains acceptable mold hardenability. The toughness of these new AM materials is proving superior to the conventional material at the same hardness, which results from superior melting and processing to produce the powder and the subsequential microstructure available for AM parts.

Consider Consistency and Characteristics

When it comes to AM materials, mold builders and plastic injection molders are looking for consistency as they would with traditional mold materials. It is not just the properties of the materials but also the characteristics of the powder—chemical composition, particle size distribution, particle shape, particle flowability and particle density—which is part of the AM inspection certificate that accompanies the AM powder.

The good news is companies with long histories in specialty steel production are the ones developing these new AM tooling materials and working with industry groups to develop standards for AM metal powders. Now is the time to look at these advanced mold steel powders.

For More Information

International Mold Steel / 859-342-6000 / imsteel.com

Paul Britton, President, International Mold Steel / 859-466-0981 / britt@imsteel.com

Dale Wilt, Technical AM Powder Sales, International Mold Steel / 724-396-3056 / dcwilt@verizon.net

Related Content

Large Hybrid Steel Insert Solves Deformation, Dimensionality, Cycle Time Problems

DMLS printers using metal additive powders selected by Linear AMS to produce high-quality, accurate, consistent 3D-printed mold components with certification and traceability.

Read MoreHow to Supply Cooling to Additive Tooling

Additive tooling provides limitless options for cooling a mold’s difficult-to-cool areas.

Read MoreAdvancing Moldmaking and Plastics: Trends in 3D Printing, Automation and Sustainability

NPE 2024 showcased the latest trends and technologies in innovation, efficiency and sustainability for moldmakers and molders, featuring advancements in 3D printing, automation, design and virtual reality/augmented reality/artificial intelligence.

Read MoreHow to Make Data Work for Mold Productivity and Performance

The use of digital workflows improves the impact of mold design libraries, conformal cooling and machine learning.

Read MoreRead Next

Breaking the H-13 Stereotype For the Common Mold

A look at the new grades and steel making practices that are available to address the day-to-day issues that occur in the operation of a mold.

Read MoreMold Steel Composition Streamlines Moldmaking Process

A mold material’s performance characteristics, like uniform hardness and dimensional stability, enabled Dramco Tool Co. Inc. to build a compression mold faster and more economically.

Read MoreHow to Design a Mold with Additive Tooling

Designing molds with additive tooling implementation in mind requires blending traditional mold standards with innovative new ideas of what is possible to push the limits of mold performance.

Read More