Build

Controlling Your Hot Runner Manifold System

Moldmakers and molders need to better understand modern hot runner controller technology to solve processing problems.

Read MoreCryogenic Machining Eliminates Moldmaking Conundrum

As moldmaking material gets harder and more expensive to cut, suppliers are “caught between a rock and hard metal,” balancing production costs with customer needs. Cryogenic machining with through-tool liquid nitrogen makes production of longer-lasting molds efficient and affordable.

WatchNew Trend Forecast Released: 3D Printing's Imminent Impact on Manufacturing

"3D printing’s greatest value is not as a technology, but as an enabler to derive greater business value." This is the main finding of a new independent survey sponsored by Stratasys Direct Manufacturing that was revealed to the press this week.

Read MoreVIDEO: A/C Servo Combination Wrist in Motion

The type of wrist paired with a robot can directly impact mold design.

WatchAchieving Efficient Filtration

Filters and media choices are key to removing dirt during the EDM process and producing smooth, even finish surfaces.

Read MorePutting Design in the Driver’s Seat

Being an engineering-driven mold manufacturer has dramatically impacted this shop’s efforts to automate processes, develop its workforce and expand into new types of business.

Read MoreMachining Complex Contours

Advanced, integrated processor geometry eases processing and predicting of turn-mill contour operations and residual grinding stock allowance.

WatchConsiderations for Assessing Robotics Requirements

Knowledge of part de-molding, end-of-arm tooling construction, part defects caused by the mold-robot interface and available automation options is key for suppliers looking to add greater value.

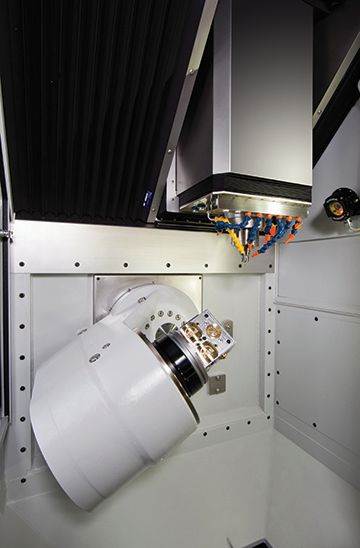

WatchProductivity Meets Precision

With machine dynamics, mechanical design and thermal stability in control, mold manufacturers can take five-axis machining to the next level.

WatchRethink Moldmaking with Digital Tool Knowledge

Connecting digitized tool data with CAD/CAM, presetting, production and automated inventory control offers real-world productivity gains.

Read More