High-Feed Face Mills Offer Speed, Versatility

Two new cutters not only improved machining speed at this mold manufacturer, but also showcased the potential of some high-feed tooling for heavier, deeper cuts.

Sometimes, it’s best to saddle up a new horse with a new rider sooner rather than later. It may help you win the race.

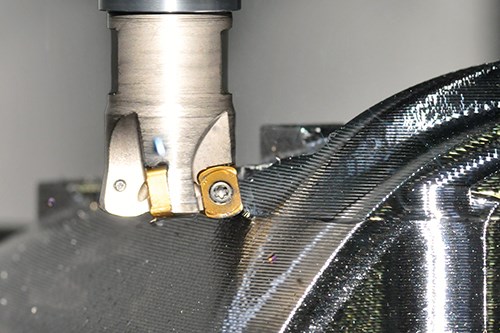

This contrarian wisdom paid off when Reko Manufacturing Group, part of Reko International Group, acquired its first five-axis machining center last year to enhance moldmaking operations. Throughput improved, but Reko wasn’t done yet. Switching to a new high-feed cutter, Ingersoll’s Power-Feed+ Mini face mill, doubled throughput and enabled the machine to run completely unattended. Following that success, the company retooled two more machines, this time with the Hi-QuadF, another variety of high-feed face mill from the same supplier. This change led to not only faster machining, but also the realization that some high-feed tooling can handle heavier, deeper cuts as well.

New Machine, Old Tooling

Located in Lakeshore, Ontario, Reko designs and manufactures molds ranging to 4,000 tons, largely for automotive suppliers. Just as expected, the addition of a DMU 210P five-axis machining center from DMG MORI delivered substantial throughput gains in cavity semi-finishing and finishing operations on these tools. However, it soon became apparent that the company wasn’t realizing the full potential of its new machine.

Further investigation revealed that moving to five-axis brought out the inherent shortcomings of the company’s standard button cutters, says Tom Hunt, manufacturing supervisor. “Tooling deficits in so-called high-feed button cutters can hide within the more limited range of motions inherent in three-axis processing. We had to slow down in the corners for reasons that no longer exist in the five-axis environment.” He also noticed corner violations and chatter problems whenever he tried to push feed rates to levels made possible by the new machine.

Fast, Consistent Feed Rates

Seeking a solution, Hunt called Shaun Towe of distributor Ramstar Carbide. Towe had heard of successes with the Power-Feed+Mini mill in stateside mold shops, so he brought along Ingersoll’s Paul Poirier to size up the application and run a demo on core blocks in hardened P20 tool steel.

At 600 sfm and 0.020-inch stepover, the face mill ran at a feed rate of 900 ipm. That’s a 9-to-1 increase compared to the old button cutter, which fed at only 100 ipm using the same synthetic, water-based cutting fluid and required 100-percent attendance because of unreliable insert life. Moreover, the Power-Feed+Mini maintained 900 ipm throughout the entire cut, including the corners. Chatter and corner violations also disappeared. In addition, the projected 5-to-1 increase in tool life raised the possibility of unattended operation, which wasn’t possible before.

However, Hunt wasn’t ready to commit to the new cutter just yet. First, he ran competitive trials against similar high-feed face mills from other manufacturers. In terms of pure material-removal rate, the Ingersoll tool outperformed two of the other tools and equaled the third. However, he recognized that the Power-Feed+Mini would help save on consumable costs because its inserts offer four cutting edges, compared to only two on the others.

The face mill’s performance is largely a function of insert geometry, Poirier says. “It looks like a rectangle with radiused ends, which do the cutting,” he explains. “This enables a smaller tool to cut as fast as a bigger one, yet go deeper into the corners of mold cavities and turn the corners without slowing down.” He adds that the inserts are thick and feature the classic high-feed geometry, in which a positive rake face reduces cutting forces and chatter.

Streamlining Roughing

Poirier’s input didn’t stop with finishing and semi-finishing applications on the new machine. While walking the floor at Reko, he also observed a potential opportunity to improve roughing operations on the company’s gantry mills, which it designs and builds in house. These rugged machines feature 100-by-135-inch X-Y travel, 100-hp spindles with speeds ranging to 3,000 rpm and 300-ipm feed rates—muscular, but not really high-feed. Reko’s standard parameters for roughing on these machines are 600 sfm with 0.05-inch-deep passes at 150 ipm.

Experience from other applications led Poirer to believe these operations could be improved with a Hi-Quad F high-feed roughing face mill running at medium feeds. “Although it’s a high-feed tool, the Hi-QuadF has the geometry to take much deeper cuts where the feed rate is limited,” he explains. “It combines high-feed and deep-cut geometry in the same tool.”

The Hi-QuadF also incorporates an IN 4030 grade aluminum oxide coating, which is deposited by a pressure vapor deposition (PVD) process to create a more durable bond. The insert is etched more deeply to enlarge the gripping area, and then the PVD coating is deposited at a lower temperature than the chemical vapor deposition (CVD) process. According to the manufacturer, this leaves a smoother, slipperier surface with fewer micro-cracks.

A trial on a hardened P20 mold component several weeks later confirmed Poirier’s suspicions. Speeds and cutting depths were left unchanged, but the tool ran at 300 ipm—twice the previous feed rate. The process ran quietly, chips came off smoothly, and the as-machined surfaces looked just as good after three hours as they did after six hours with the previous face mill.

Reko and Ingersoll then repeated the test at the same parameters, but on soft tooling. Throughput tripled, and projected tool life improved to 10 hours in the cut, compared with only 4 hours before. What’s more, during both trials, Hunt noticed that spindle load dropped from 60 percent to 20 percent, despite doubling the material-removal rate. “Now that’s free cutting,” he says, crediting the smoother, slicker IN 4030 coating for the improvement. Finally, just as he did with the new tooling on the five-axis machine, he verified that the Hi-QuadF would outperform other, similar tools prior to committing.

More Than Meets the Eye

“These two applications show two things about high-feed tooling,” Poirier says. “In the semifinishing case, we see that there are real performance differences, even though both tools were classified ‘high-feed.’ In the roughing case, a nominally high-feed tool improved a standard-feed application. All high-feed tools are definitely not the same.”

Reko has leveraged both improvements to offer tighter delivery schedules for Tier 1 automotive manufacturers while still guaranteeing life-cycle cost (LCC) pricing. “Now our in-house costs compare favorably with those of offshore suppliers on a larger percentage of the molds we make,” Hunt says. “The more we can economically do here in Ontario, the better we can serve our customers.”

Related Content

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreFundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.png;maxWidth=300;quality=90)