Precision Electrolytic Machining

Create tools with high tolerance, precision and a smooth surface finish with precision electrolytic machining.

Aniche process is now being launched in the U.S. affording companies the ability to address a variety of manufacturing efficiencies in precision metal machining: Precision Electrolytic Machining (PEM). It offers several advantages in the manufacturing of molds and dies including: full form machining of multiple parts or multiple features in one operation; features are machined with

excellent surface finish and do not require secondary finishing; and small radius at feature bottom is possible with PEM.

For many years, electrochemical machining has been used

in automotive, aerospace and medical manufacturing for machining components to tolerances of a few thousands of an inch. PEM is based on the electrochemical machining metal removal principle.

Electrolytic machining is based on the Faraday principle of electrolysis. This machining process is often characterized as reverse electroplating, in that it removes material instead of adding it. Metal removal is achieved by electrolytic dissolution of a metal surface connected to the positive polarity of a

DC power source in an electrolytic cell. The cathode (tool) determines where material is removed from the anode (workpiece) by proximity of the tool to the workpiece.

The anode metal dissolves electrolytically—and its rate of dissolution depends only upon the atomic weight and the ionic charge, the current that is passed, and the time for which the current passes, which is Faraday’s Law. The dissolution rate is not influenced by the hardness or other characteristics of the metal. Since only a small amount of hydrogen is evolved at the cathode, the shape of the electrode remains unaltered during the electrolysis. Therefore, material removal is principally determined by current and time.

The PEM process is an advancement of electrochemical machining that incorporates pulse power and an oscillating cathode tool that can machine even hard metals to less than athousandth of an inch. This innovative machining concept advances a cathode (tool) into an anode (workpiece), pulses the metal removal current while in close proximity (typically 10 to 20 micron gap) then retracts. As electrons cross the gap during the pulse, material on the workpiece is dissolved, as the tool forms the desired shape. Pressurized electrolyte is injected at a set temperature while the gap between tool and workpiece is open to flush away the metal hydroxide formed in the process.

Machine Tool Components

The PEM machine tool consists of four major components as shown in Figure 1 (page 19): machine, power, environmentally-friendly automated electrolyte system and control.

The machine is constructed out of granite and stainless steel and tolerances are held within micrometers. The pulse power source provides machining power that is synchronized with the oscillating head of the machine. The environmentally-friendly automated electrolyte system provides micro-filtering with variable flow rate, at controlled pH, conductivity and temperature. The precision machine control has a decentralized distributed intelligence to control the process and to regulate and monitor relevant machining center functions. The PC-based system with touch-screen interface provides for ease of operator input and graphical status display.

Surface Finish

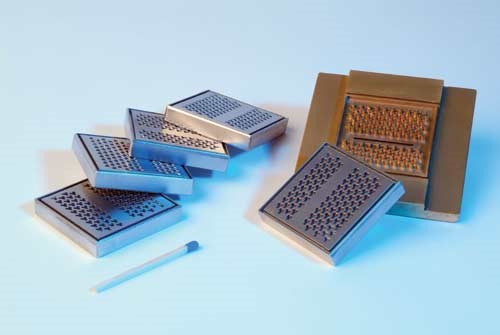

Precise shapes—such as gear teeth—with excellent surface finish can be created with the PEM process. For example, four gears, like the stainless steel gear in Figure 2, can be machined simultaneously to final form and surface finish. Typical machining rates are .04 to .05 inch per minute.

Since the PEM process is a stress-free metal removal process that removes metal from the surface atom by atom, there is no possibility of forming burrs or mechanical deformation at edges.

High quality tools and dies can be machined without the concern for burrs being introduced into the final product. Although surface finish is material dependent, many materials are machined to very smooth finishes with some as good as 1-4 in Ra.

Full Form Machining

PEM is a full form precision machining process that removes material as an area machining process. Therefore, machining usually starts with a solid blank or a preform of the component geometry.

Punch dies are another example of an application of PEM (see Figure 3). Hardened punch blanks can be machined to final form and surface finish for a variety of shapes.

Molds and Dies

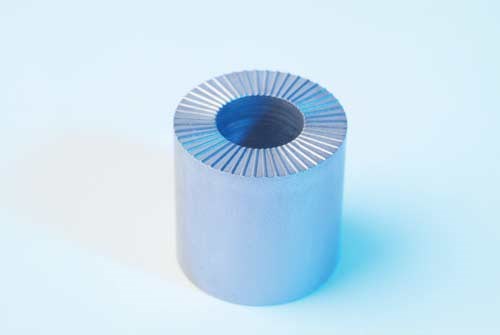

PEM has many applications within mold and die (see Figures 4-9), including multiple cavity moldmaking capabilities; creating knurling tools for fasteners (four parts machined in four minutes) and engineered surfaces for sealing surfaces on gasket dies; various marking dies for roller bearings for cars; creation of inset pieces in plastic dies for date stamping purposes; marking dies for engine blocks; pill dies for pharmaceutical industry; and compacting dies (shown with cathode).

Summary

With the launch of PEM Technologies in North America, today’s mold manufacturers have a new technology to turn to. The PEM process should be considered by mold manufacturers who covet excellent surface finish, precisely finished workpieces, without burrs, and the ability to create small radius at the feature bottom. In addition, since the PEM process is a stress-free metal removing process, there is no possibility of mechanical deformation of surfaces or edges.

Read Next

Machining Madness: Advances in HSM

The industry’s demand for higher quality, faster turnaround times and lower prices in the last decade has resulted in dramatic improvements in high speed machining as well as controls and spindles.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More