Measuring the Effectiveness Of Your Mold Machining Ops

A review of the shortcomings and solutions to OEE challenges.

Many machine tools used in moldmaking are

poorly set up for the data collection and communications needed to measure the Overall Equipment Effectiveness (OEE) information needed for profitable company decision-making. There are historical reasons for these shortcomings, along with industry and research solutions emerging to address them.

Reasons for Obsolete Technology

In the 1980s, CNC machines with RS232 serial ports for communications with computers emerged. Programs were stored on a PC, backed up or called up remotely, and were much easier to manage than punched paper tape. The approach was so successful that many of these controls and machines remain in use today.

The main weakness of RS232 serial port technology is the length of the cables required in a shop floor environment. Longer cables require slower data transfer (< 2400 Baud) rates, and increase the risk of data transmission errors. The harsh environmental conditions of some moldmaking shops can cause PC failures that interrupt day-to-day operations.

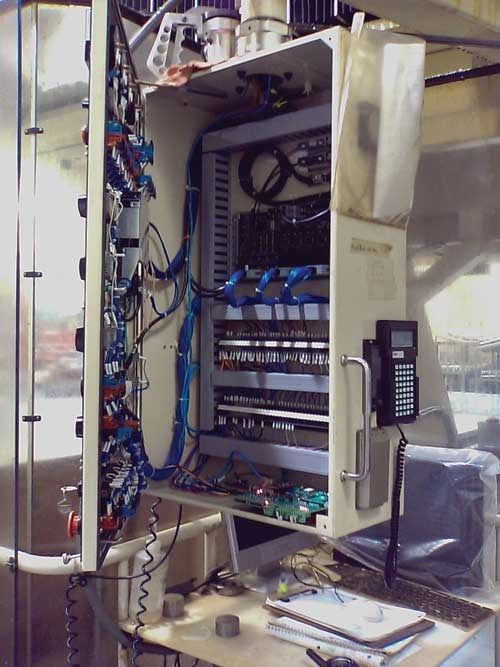

In today’s competitive mold manufacturing environment, these failures are no longer acceptable. Migrating to the ethernet for networking connectivity is the solution. Conversion to a company-wide, ethernet-based machine tool communication network, (while still loading and accessing a machine through a local, legacy serial port is cost-effective) has a short return-on-investment (ROI) period. It also provides the easiest migration path to reliable shop floor information and increased operational efficiency.

There are advantages to migrating from serial to ethernet communications on the shop floor, including machines communicating directly with corporate information systems, increasing operational efficiency. Available applications provide real-time machine monitoring, acquisition of OEE metrics, dynamic CAM, automatic synchronization of part programs, DNC, work order scheduling and central control of machine operations.

On the research front, earlier this year, during a keynote address at the Canadian Manufacturers & Exporters conference held in Ottawa, Canadian Minister of Industry, Tony Clement announced funding for several groundbreaking, large-scale, multidisciplinary research projects. Included was the NSERC Canadian Network for Research and Innovation in Machining Technology (CANRIMT), led by Dr. Yusuf Altintas of The University of British Columbia. The five-year, $5 million network involves university researchers from across Canada working in modeling, analysis, monitoring and control of machining processes and manufacturing automation.

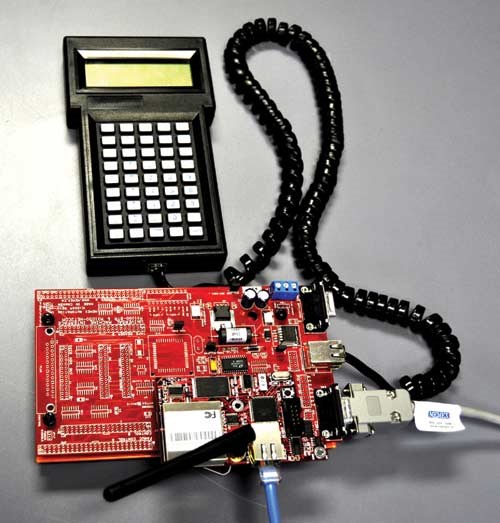

Dr. Allan Spence at McMaster University comments on additional collaboration with other industry participants*, “This is a special opportunity to advance virtual machining technology through integration of laser scanning and CAD algorithms with online monitoring, measurement and control. This funding will allow us to more precisely predict and control mold machining operations—even for cases where actual geometry departs from CAD actuals. To accelerate industrial adoption, we will be using the Memex* Ax9150 Universal Machine Interface with our CNC machine tools.”

How to Technologically Advance

Traditionally, the continuous process sector has provided leadership in adopting and using efficiency metrics. The simple observation is that continuous processes deploy very expensive ($20K to >$1M) process control MES systems at initial deployment. These systems directly capture the relevant information needed to report appropriate metrics.

In contrast, because discrete part production (e.g. CNC) errors are limited in scope, moldmakers can rarely justify the expensive MES systems. New machine interface hardware has reduced this expense to $4,000 per machine, making OEE metric collection affordable. The ROI is very rapid, with reports of 20 percent or greater productivity improvements.

“Operator-less” Input

Because the OEE system can automatically accept signals directly from the machine tool control, unless there is a fault or other downtime event, there is no longer a need for the operator to provide input for each cycle. This direct and real-time capability avoids ERP data entry issues with operator errors, failure to record and lost hand-written reports. The OEE system saves significant labor time—often justifying the investment even before the benefits of increased efficiency, lower product costs and competitive advantages are factored into a cost benefit analysis. This is considered the most critical factor to moldmakers as it removes the human element and there is accurate data with built-in monitoring tools and alerts. If you can measure it, then you can manage it.

OEE Benefits

From a moldmaker’s perspective, OEE provides valuable new benefits. Here are some recent comments received from both management and shop floor users:

- “We now have a tool to communicate to the people on the shop floor that our performance can improve.”

- “The OEE data provided improves human as well as machine-to-machine communications.”

- “We believe we can use data to motivate employees with a shared understanding of how we can be more productive, and that’s what it’s all about.”

- “Our biggest differentiator is productivity and OEE helps us identify areas to improve our efficiency.”

- “Machines are islands of unconnected information—like having a group of office PCs, each with different software—now we can network machines together, just like networking an office.”

- “We had passive OEE with manual clip boards and now we have active OEE, visible in the plant.”

- “The key to better productivity is not just to track performance, but to act on problems in real-time.”

- “Machine connectivity unites the islands of machine automation, establishing a fully-connected, enterprise-wide manufacturing nervous system that gives real-time visibility of production and the ability to adapt and control each machine.”

- “Customers can see and believe in what we’re doing to improve on-time delivery because we have traceability of machine operations through OEE.”

The Future Is Bright

Moldmaking has entered the 21st century. Global technology initiatives from technology suppliers, coupled with university research—such as the NSERC CANRIMT initiative—recognize that the machine tools used in moldmaking are uniquely poised for evolution to new communication capabilities, OEE measurement and CAD-based virtual machining advances.

*Memex Automation, a business unit

of Astrix Networks Inc.

sales@memex.ca / memex.ca

Related Content

What Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

Read MoreMMT Chats: 5 in 5 with Best Tool and Engineering

MoldMaking Technology Editorial Director Christina Fuges reveals 5 best practices for improving efficiencies within shops...in 5 minutes. Our guest is Joe Cherluck, President of Best Tool and Engineering in Clinton Township, Michigan.

Read MoreLeading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

Read MoreUsing CT Scanning to Qualify Molds Faster

Software and hardware advances reduce dimensional inspection with part-to-CAD by 70%.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)