Modular Technology on Demand

An upgradable approach to flow-control technology offers flexibility and could help ease the decision on whether the technology is worth the investment.

Developments in control technology for hot runner valve gates have greatly expanded the molder’s ability to understand and control valve-pin movement. These developments range in their levels of complexity, control and benefits, and some require upfront investment. There are ways to help determine when that investment is warranted, however.

Obtaining feedback is the first step toward understanding and controlling valve gates, and this can easily be accomplished by adding a position sensor to each actuator. A simple device with status lights, like the one shown in Figure 1, can be used to indicate the pin’s position and speed at any time during the molding process. The operator can quickly and more safely identify setup errors without the need to physically check the current pin position from inside the press. Molding defects, potentially caused by improper or inconsistent pin movement, can be easily and quickly diagnosed without stopping the cycle. Preventive maintenance can be scheduled based on changes to the responsiveness of the pin over time. These changes might otherwise have gone unnoticed until increased scrap rates prompted an investigation.

Simple feedback leads to the next advancement in valve-gate technology: control of the valve pin’s opening speed. This is particularly beneficial in cascade molding, which is used to eliminate weld lines on multi-gated parts. In this type of molding, the part is initially filled from one gate while opening of the other gates is delayed until the flow front passes each of them. The delayed gates are then opened, introducing the melt behind the original flow front and preventing the formation of weld lines. Although cascade molding is able to improve part cosmetics in this way, its sudden flow-front accelerations and stagnations can cause other surface defects. For example, as the cavity is filled, pressure builds up behind the delayed pins, and when they abruptly open, pressurized melt surges into the mold cavity. This causes a sudden change in pressure within the cavity, resulting in a line of differential gloss called a pressure line.

Some valve-gate technology solutions reduce the speed of the pin for its entire stroke, but this is not necessarily ideal. Generally, these technologies include manual flow-restrictor valves in the hydraulic circuits that meter the flow of the hydraulic fluid to the valve gates. They tend to be less expensive than higher-end technologies, but slowing the valve-pin speed for the entire opening stroke can create excessive shear, pressure loss, shear heating and stress, which often leads to other problems.

More advanced technologies enable the user to slow the initial opening speed of the pin only for a set distance. This allows a controlled release of the pressurized plastic behind the pin during cascade molding. Once the pin reaches the predefined point in its slow opening movement, it opens at full speed for the remainder of its stroke, avoiding the excess shear and associated part defects that often occur with one-speed technologies.

Such two-stage speed control is extremely important when there is a significant flow length remaining in the part after the melt front reaches the delayed pin. In addition to employing sensors on the actuators to get feedback on pin position and speed, these types of technologies also take advantage of electronically controlled flow-restrictor valves and control units, allowing the user to set an initial open speed and the stroke for which that speed will be controlled.

Still other hot runner developments offer complete control over the pin’s movement, allowing the operator to set multiple speeds, acceleration and stroke for each valve pin’s opening and closing movements. There are several technologies on the market today that provide the same capabilities as the monitoring and controlled open-speed technologies, but also allow the user to balance tools, fill extremely complex multi-gated parts, reduce warpage, cut clamp force and even trim part weight. Initial systems used electric motors to drive the pins, but hydraulic or pneumatic versions now are available with proportional valves instead of the standard solenoid directional valves that are typically used to actuate pins. Unlike conventional directional valves that simply supply pressure in one direction or the other, proportional valves can supply varying amounts of pressure to both sides of a hydraulic piston simultaneously. Combining proportional valves with actuator sensors and a control unit gives these fluid-powered systems the same complete pin control previously only obtainable through electric systems.

Even more advanced technologies are also available that use much of the same equipment, but go beyond controlling a valve pin’s position and movement. For example, a system that adds a pressure sensor and melt flow control valve inside the hot runner enables the user to set individual

fill and pack-pressure profiles for each hot runner nozzle. This takes pressure control away from the injection molding machine and moves it to multiple points of injection within the mold, essentially giving the control of a separate injection unit at each hot runner gate. This ability to manipulate the filling of the part at each gate location offers a level of flow control that has opened the door to more challenging applications, such as molding families of tools with extreme differences in required fill pressure.

Balancing Benefits and Costs

As beneficial as these valve-gate technologies can be, they do add to upfront tooling costs and to the overall complexity of molds. The challenge for the moldmaker and molder is determining when the additional investment is warranted. Obtaining simple feedback only requires position sensors on the actuators, a junction box for the connection to the mold and a monitoring device. However, the more advanced technologies can require controllers, valves, additional connections and, in many cases, an interface to the injection molding machine. All of this extra equipment adds costs, can increase setup time and adds complexity to the process.

Electric systems, for example, require a special electric valve-gate controller to actuate the pins. If such a hot runner is sent back to the mold builder for maintenance, and that maintenance requires the pins to be actuated, the moldmaker will not be able to move the pins without the corresponding controller. Systems may also require an interface that allows the injection molding machine to communicate with the controller, which handles the sequencing of the electric valve pins, in order to operate properly. This can be an issue if a mold is moved to a different machine or a new molding plant on short notice.

Filling analysis can help moldmakers and molders determine if the additional valve-gate control will warrant the added costs and complexity to the molds and processes. The results of this analysis can help anticipate pressure-line defects caused by the sudden pressurization of the cavity when a delayed pin is opened in a cascade process, for example.

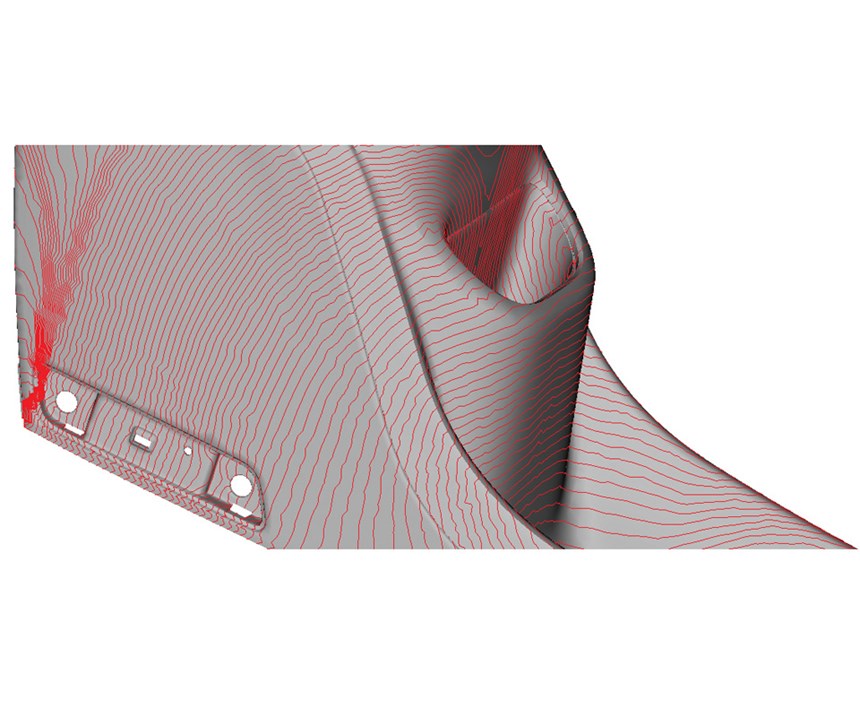

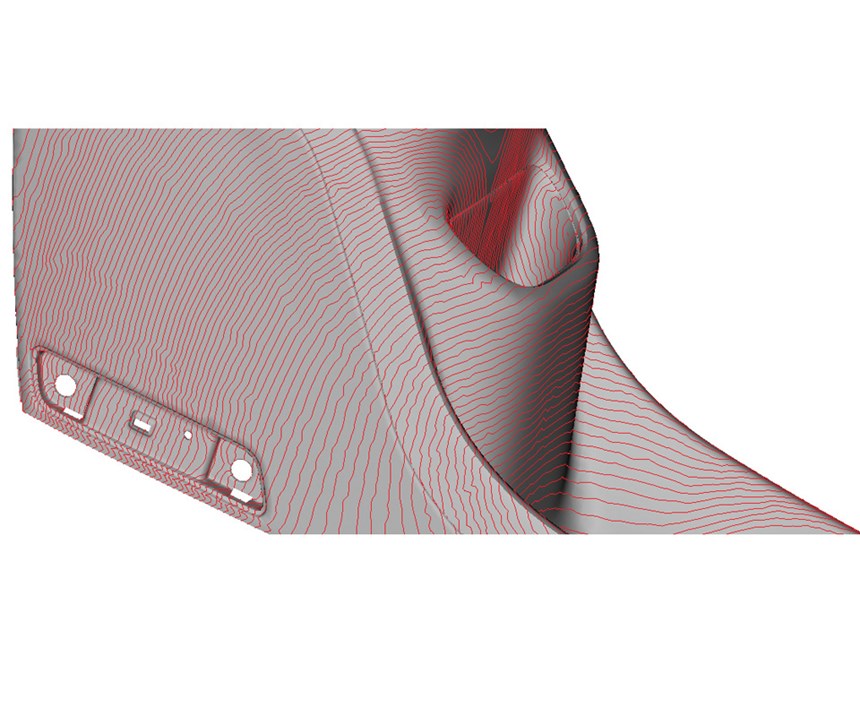

Figures 2 and 3 illustrate a fill-time contour plot of the position of the flow front at consistent time intervals. This visual representation quickly reveals any sudden flow-front accelerations or stagnations. Increasing distance between the lines indicates the flow front is moving faster, while decreasing distance means the flow front is moving slower. Sudden changes in flow-front speed can show up as a sudden change in gloss on the finished part’s surface. Some filling analysis software can also simulate the impact of more complex pin movements.

Of course, filling analysis is only a tool for identifying potential issues and does not guarantee an unacceptable resulting part. Real-world experience with similar parts molded with similar materials is usually the best guide. Even then, however, it is not uncommon for an anticipated defect or filling issue to not show up when the part is actually molded.

Using an Upgradable Approach

Evaluating the needs of the mold prior to making the investment in a new flow-control technology is essential to making the right decision. Hydraulic or pneumatic hot runner systems can now be supplied in a “ready” state, with position sensors on the actuators. These pin-position sensors enable the systems to be easily upgraded in the field, and the advantage of this upgradeable approach cannot be overstated: commitment to any specific level of technology at the time of the mold build is not necessary. The ready system can be easily tested with different levels of flow control to find the level of control that suits the particular application. If the process might benefit from further pin control, the necessary flow-control equipment can be easily added after the fact. If it is determined that the part can be acceptably molded without any additional equipment, the sensors installed on the ready system will still provide value through a pin-position monitoring device (see Figure 1).

In many cases, all of the necessary flow control equipment can be mounted on a stand-alone cart or as part of a hydraulic power unit. These stand-alone units the can be positioned next to the press and easily connected to the mold with a ready system (see Figure 4). This can facilitate quick, unscheduled samplings of technologies that otherwise would need to be planned for months in advance.

As you can see, developments in hot runner valve-gate control offer new capabilities, but some require a commitment to upfront costs, process complexity and limited flexibility. Others, such as newer hydraulic and pneumatic “ready” systems, allow a mold to be tested before a flow-control technology upgrade, leaving the door open to possibilities without forcing premature commitment.

Related Content

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreMachine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

Read MoreMaking Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.

Read MoreThe Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More