Multispeed Valve-Pin Control

Eliminating hesitation marks is easier and more cost-effective with multi-speed hydraulic technology.

Sequential hot runner technology has most benefited the medium- to large-sized plastic injection mold market, particularly automotive, over the past 20 years. The ability to control the filling of a part with valve-gated and heated channels has given way to bigger, more complex parts, larger processing windows and significant part-cost reductions. As the technology has matured, the quality demands of OEMs and Tier-One suppliers have grown to a point where processing windows are tighter and certain part defects are no longer acceptable.

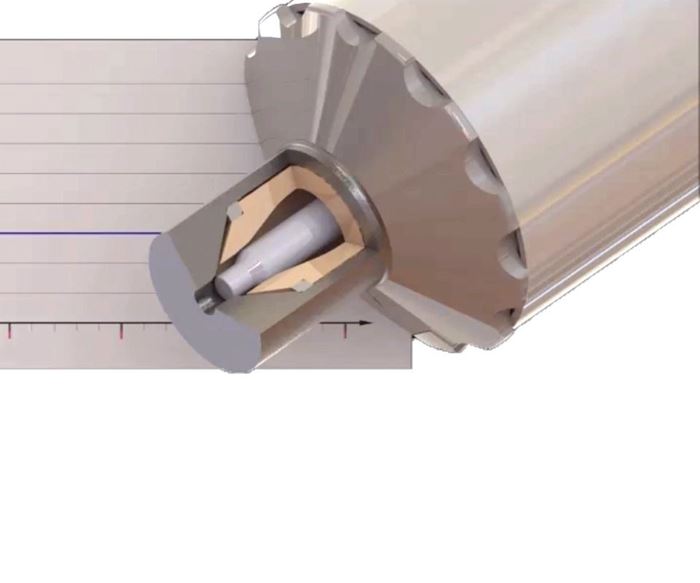

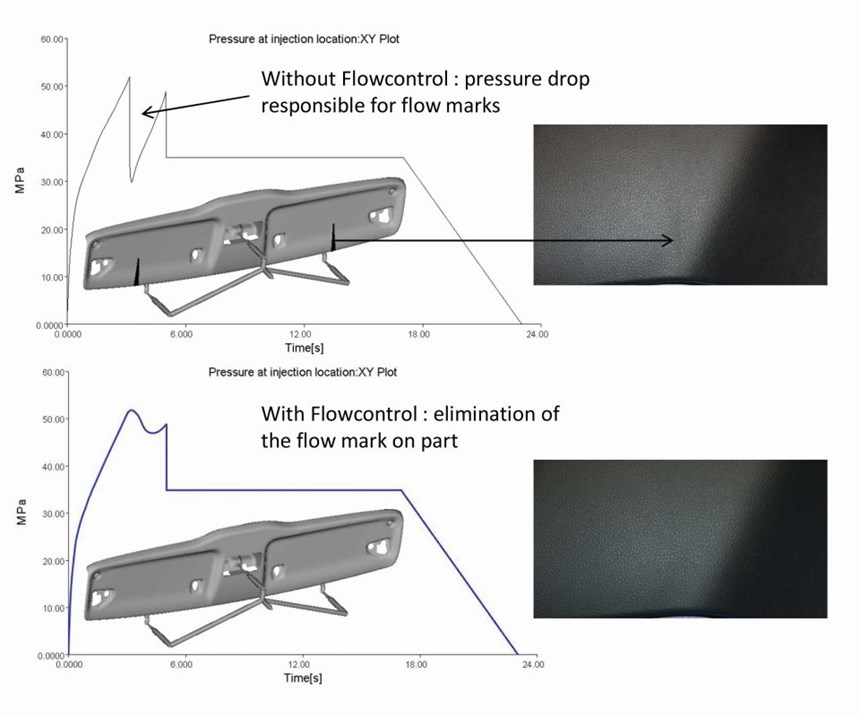

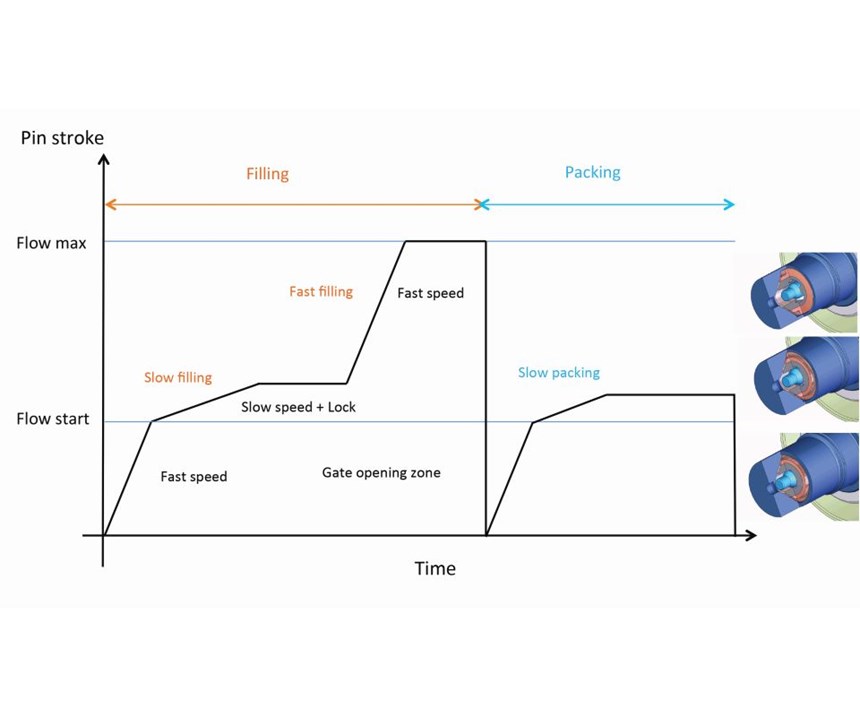

One of the most significant demands in this sector is for eliminating hesitation marks. These occur when a new valve gate opens in the molding sequence, and they are best detected by a sudden decrease in plastic pressure in the hot runner system. The industry has widely agreed that the solution to these defects is to slow the opening of the valve pin (see Figure 1).

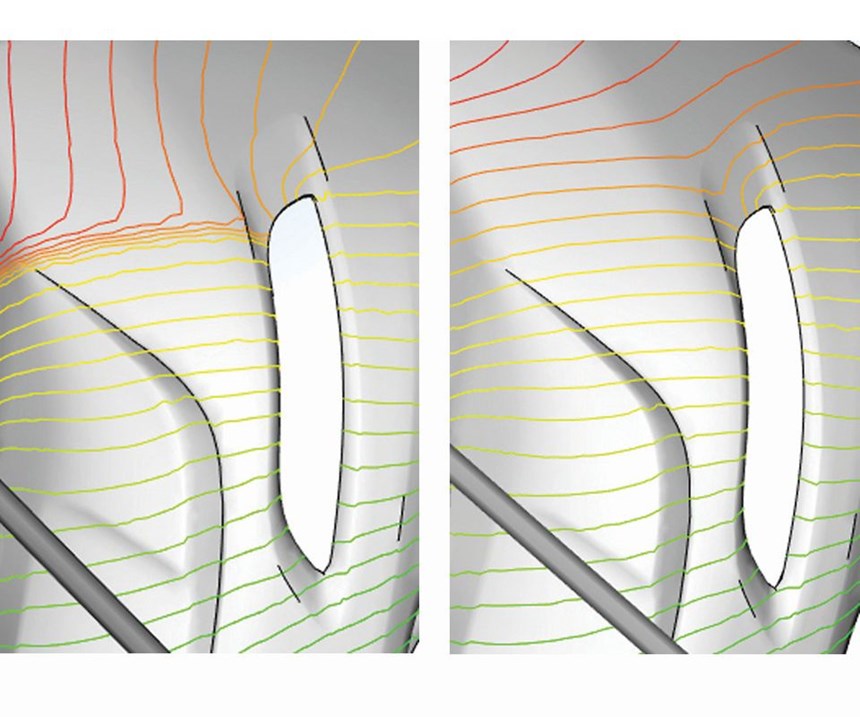

The speed-controlled valve pin creates a restricted plastic flow that reduces the sudden rush of plastic that occurs when a new valve gate opens in the molding sequence (see Figure 2). The restriction allows the previous gates in the sequence to continue filling and the overall fill rate of the part to remain the same. This strategy of maintaining a uniform filling rate can eliminate hesitation marks and other flow-related defects.

To date, speed control has been achieved through the use of closed-loop, electrically driven, hydraulic-proportional valves or electrical servo-driven valve pins. Although these solutions are viable methods for removing process-driven defects, they drive up costs by requiring investment in proprietary controller technology and special training. This is where the need for a cost-effective solution with simplistic processing controls arose.

The Multi-Speed Solution

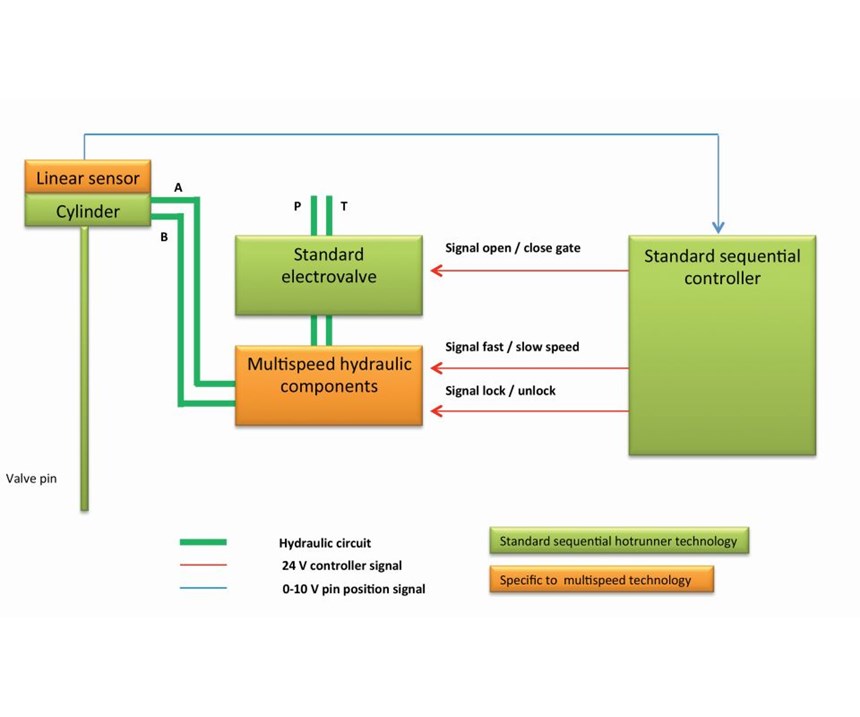

Now there is a multi-speed hydraulic solution for valve-pin speed control that uses two hydraulic flow control valves; a locking valve; and a valve-pin-position sensor.

The use of hydraulic flow control valves is nothing new to sequential valve-gate speed control, but the single-speed system could not restrict the plastic flow enough to eliminate many of the desired marks. Multi-speed technology yields a greater degree of molding freedom that is not available in a single-speed solution due to its ability to open the gate on demand and even lock the pin in its stroke.

In this multi-speed solution, a standard 24-volt solenoid opens the gate, while the speeds are controlled by two flow control valves (see Figure 3). Users can choose high speed, low speed or position-lock/zero speed. The choice of valve pin control is dependent upon the results from mold trials and requires the process technicians to tune gate timing and valve speed to remove the desired defects.

This solution is designed to function with standard valve-gate controllers already in use at the molder’s plant, but with modified valve-gate controller connections. Instead of one 24-volt output per gate, the standard controller uses up to three per gate and a 0-10-volt sensor input for each.

With the multi-speed system, the fast speed is the default and is used to move the valve position to a start-of-flow state (intrinsic of cylindrical gate technology). Then, using the pin-position sensor as a trigger, the process technician will set the valve-gate controller to switch to the slow speed to create the flow restriction necessary to eliminate flow-related marks (see Figure 4). A zero-speed/pin lock can also be used to lock the pin in any position when restricted flow is required for better part quality or lower plastic throughput. To use the multi-speed control during the packing phase, the valve-gate is closed after the injection phase and then reopened immediately using this same fast-to-slow/zero-speed method described above.

Process Extension

Multi-speed technology acts as an extension of the molder’s current system. Existing controllers are used, and the programming logic does not change. The valve gate is initially opened by selecting the time or screw position on the controller for the open signal, and will function as a normal gate just by doing this operation. To activate the multi-speed technology, the process technician uses another output on the controller to select the valve pin position at which the slow speed or position lock will occur. The multi-speed technology becomes an extra valve gate on the controller, which means programming remains the same and the training required to operate the technology is greatly reduced. By using the existing valve-gate controllers, there is no capital investment required by the molder, and the valve-gate controller can be used with other molds on the same press.

Multi-speed valve-pin control technology can bring a new level of control to injection molding at a reduced cost and is an extension of the sequential hot runner system. Hot runner systems that are already in design or in production can be retrofitted with the technology without mold or hot runner modifications. It is a bolt-on, modular concept that extends the process windows of your molds without having to purchase it from the start.

Related Content

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreHow to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreIt Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read MoreRead Next

Smart Tooling

Combining cavity sensors with hot runner valve gate control yields new applications and greater process gains.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More