Engineer

Minimizing Costly Tooling Issues

Properly reviewing a mold design before manufacture can help avoid new tooling issues.

Read MoreBeyond Integration

CAD/CAM integration has reached an entirely new level of value within process planning.

Read MoreDiamonds in the Roughing

This mold manufacturer discovered significant time and cost savings in a previously unexplored feature of its CAM software.

Read MoreCAD/CAM Upgrades Speed, Simplify Tool Build

A surfacing module and NC template technology are among the software features that help this mold manufacturer unleash the full potential of its equipment and its staff.

Read MoreDesign Right the First Time

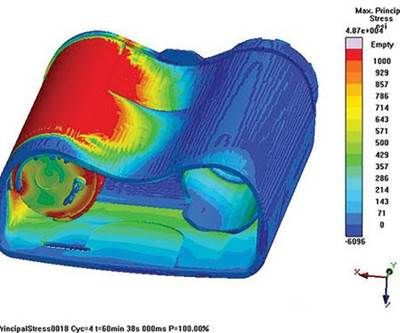

Simulation of both the induction heating and injection molding processes optimizes cycle time and final part results.

Read MoreMachining 3D Parts

For most of the 3D machining required in moldmaking, there are essentially seven steps necessary to achieve the desired results in terms of shape, finish and cycle time.

Read MoreProduct Cost Management Improves Supplier Negotiation

Certain software tools can help take the guesswork out of the process for both manufacturers and suppliers.

Read MoreThe Misunderstood Cutter Path

Normal vectors are not always the best choice for milling complex mold surfaces.

Read MoreThe Data-Driven Operation

Manufacturing is a team effort involving suppliers, tool shops and customers throughout the world collaborating and sharing project data.

Read MoreThe Pellet Enters the Melt Delivery System

Choosing a hot or cold runner system is a decision for the molder and moldmaker that must balance the processing window with budget and time.

Read More