Engineer

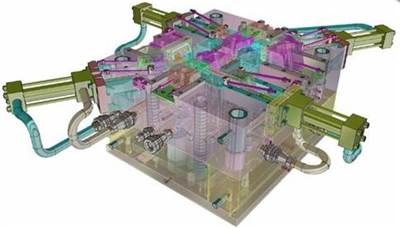

Have Designs on Conformal Cooling?

This Wednesday, April 27, MMT will host a webinar titled Practical Considerations for Conformal Cooling Designs.

Read MoreEliminate Software Clutter

An all-in-one mold design strategy can streamline the mold building process and increase accuracy.

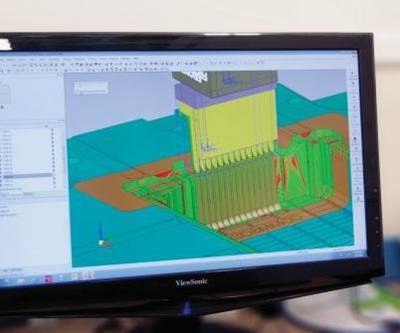

Read MoreIntegrated Software Speeds End-to-End Moldmaking Operations

Cimatron CAD/CAM software from 3D Systems helped PTI Engineered Plastics simplify the flow of its work from design to production.

WatchCooling Is a Hot Topic

Mold cooling is one of the most important elements to mold productivity because it can greatly impact cycle time and part quality, which of course affect the bottom line ... your profitability. Check out these two upcoming webinars that tackle a variety of mold cooling challenges and solutions.

Read MoreHow Much Are Those Free Estimates Costing You?

Everyone says that time is money, yet many mold builders throw it away at an alarming rate by quoting for free. Check out what one cost estimator and automotive lighting specialist has to say about this industry challenge. If companies were to start looking at their costs to provide these ‘free’ quotes, they’d be surprised at just how much this is costing them.

Read MoreToolpath Verification Optimizes CNC Machining Productivity

One shop estimates that the addition of Vericut software has helped it increase throughput as much as 20-30 percent.

Read MoreRough and Tough

What you don’t know about high-efficiency roughing versus high-speed roughing could be costing you money.

WatchIt's Not for Me

Almost every time I speak with a moldmaker about their ERP, scheduling or quoting software, they say that what is on the market is not specific enough for what they do, and they end up developing their own solution. Well, here are five questions to ask to learn if it is time to change your ERP solution.

Read MoreSeeing the Industry with a New Perspective

Last week I attended Plastec West in Anaheim, California (what a nice break from frigid temps in Chicago!). It was my first trade show as senior editor of MoldMaking Technology versus attending as a public relations manager for plastics industry suppliers, and I enjoyed seeing everything with a new perspective.

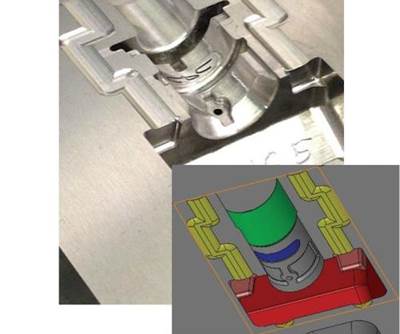

Read MoreHigh Accuracy and Efficiency CAM System Speeds Mold Building

The ability to machine smaller details into molds has reduced or often even eliminated the need for secondary surface finish operations.

Read More