Engineer

2016 Digital "Technology Review and Sourcing Guide" Available

If it's time to upgrade old equipment, try an alternative process, invest in a new strategy or just shop around, MoldMaking Technology’s annual Technology Review and Sourcing Guide is the perfect companion to your decision-making process.

Read MoreAre You Optimizing Part Design and Manufacturability?

Autodesk presented a free webinar titled “Using the Power of DOE to Design Process and Part Improvement”. If you missed it, you can still access it here.

Read MoreAIM-ing High to Serve Medical Market

During my recent travels, of which there’s been quite a bit, I had the opportunity to visit AIM Plastics in Clinton Township, Michigan, where a whole lot of medical molding is going on.

Read MoreReducing Risk in Lights-Out Machining

Surface-based CAM software can increase accuracy and make unattended machining a possibility for shops that have avoided it in the past.

Read MoreEnhanced Decision-Making

Collaborative manufacturing, combined with systematic injection molding training, can help reduce the costs and time associated with design for manufacturing.

Read MoreCAM Software/Machine Matchup Saves Time, Boosts Efficiency

A five-axis machining center and better CAM software helped this mold shop dramatically improve throughput and profitability.

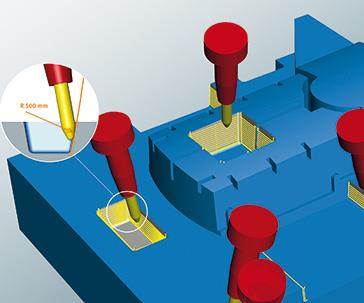

Read MoreBroadening CAM Applications for Barrel Cutters

This alternative cutting tool geometry, along with the right CAM software, can help moldmakers reduce finish-machining times.

WatchMeasurement Data Supports Manufacturing Success

Here are five ways that measurement data can be used to improve productivity and profits.

Read More5X Tangent Plane Machining

The ball end of a barrel cutter cleaning a corner feature, and then the barrel cutter quickly covers the surface.

WatchWhat Do You Really Know about Mold Cooling?

Do you ever ask yourself why cycle time matters? Although the level of impact may vary across the supply chain, one thing is certain: reducing cycle times can lead to hidden cost savings. And with cooling and recovery making up more than 80 percent of the injection molding cycle, it is the perfect place for improvement to help reduce cycle times. Listen to this webinar to learn how to achieve optimal cooling through analysis.

Read More