Beyond Integration

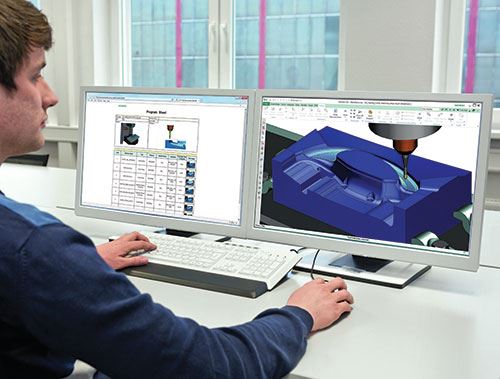

CAD/CAM integration has reached an entirely new level of value within process planning.

If you have been involved in moldmaking for a long time, you know that the concept of “integrated CAD/CAM” is not new. Using CAD data as input for machine tools was being done on a rudimentary level as far back as the early 1970s. But recent advances in CAD/CAM integration have increased its value.

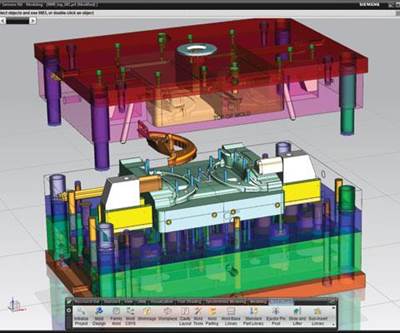

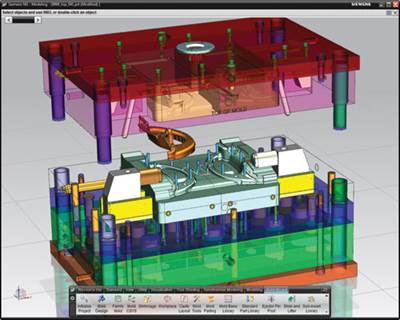

Many moldmakers are aware of the time-saving benefits integrated CAD/CAM offers in its use of design geometry as the basis for tool paths. However, there are additional benefits that extend beyond associativity, where changes to a design can automatically update the tool paths. This is a great functionality, but what if each time you began a new project you were able to quickly identify a similar mold that you had already manufactured, and in retrieving that mold you also retrieved the entire process plan—the description of every step involved in the mold’s production, from raw materials to finished product?

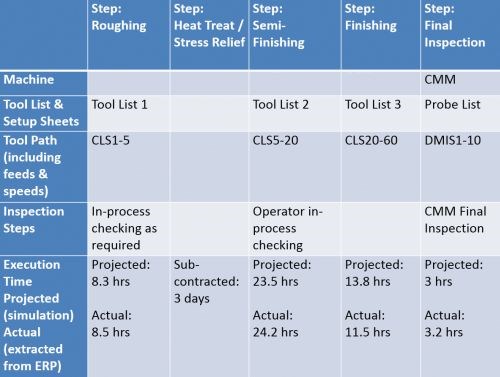

Imagine being able to adapt and reuse routings that included tool definitions, feeds and speeds, inspection steps, and execution time (see Figure 1). Or let’s say you have made several molds in the past that are somewhat similar to the new one. Your search identifies all of them, allowing you to compare all of the process plans and pick the most appropriate one to adapt for the new project.

This scenario is possible today with software advancements that allow manufacturers to speed up new mold creation by reusing existing routings instead of beginning each mold from scratch while trying to find existing designs and manufacturing plans.

3D Shape Search

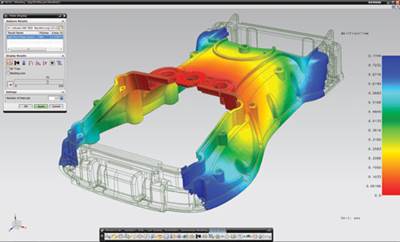

A major software development is 3D search functionality, which makes it possible to find existing molds by their shape. Conventional searches are based on metadata or attributes, and require strict conformance to naming conventions. In contrast, searching by 3D shape enables similar parts to be found, irrespective of name or classification, and the search can be seeded with a completed part or a coarse partial design. This can help users accurately estimate design costs and ultimately reduce unit costs.

Moldmakers tend to work under the assumption that each mold is unique and there is not a lot of carryover from one project to the next. 3D search functionality helps reverse this assumption, enabling users to quickly identify similar molds and reuse information from previous projects. Because 3D shape search engines locate existing molds so quickly, moldmakers can more easily take advantage of expertise developed during previous projects.

Managed Environment

The key is pairing this new search functionality with a managed environment, such as a product lifecycle management (PLM) system or data management system that serves as a single place for maintaining designs, documents and related resources. A managed environment doesn’t just store information, it provides functions such as version control, revision control and access control, which eliminate security issues that arise when moldmaking information is stored in many different locations.

A managed environment also preserves relationships between the various process elements. When a managed environment is paired with a 3D search engine, it enables the retrieval of data on similar molds, including designs and standards, as well as related CNC programs and process plans. Although best practices are not a special type of data that someone enters into the environment, they also can be revealed by the search, because the moldmaker is able to see how the production of past molds evolved and improved.

Enterprise Resource Planning

Ideally, the data environment also would incorporate information from an enterprise resource planning (ERP) system about actual past manufacturing operations. This data is different from information contained in the process plan. An ERP system would contain actual historical data related to mold “X,” for example, such as the exact machines employed, machining time required, number and type of cutting tools used, and more.

Cost Management and Training

The benefits of this higher level of integration become most apparent as new molds are created. Reviewing information about each of the individual process steps and the required resources related to similar, previously created molds also enables manufacturers to better estimate the cost and quality of the new mold.

Another benefit of greater CAD/CAM integration is that it can serve as a powerfully organic form of training for new engineers, exposing them to the best practices used by more experienced colleagues. These might include guidelines related to number and sequence of process steps and amount of leftover stock between operations, as well as required machines, cutting tools and fixtures. This incidental training does not require additional costs or planning. It can also aid in alleviating some of the challenges related to finding experienced workers.

Historically, reusing information for the next project or program has been difficult in moldmaking, because each new mold requires a new process plan, and this can lead to wide variations in processes, as different people tend to approach jobs differently. Truly integrated CAD/CAM eases the reuse of information, minimizing variations in processes and encouraging best practices. It allows shops to reduce the time needed to complete a new job, decrease job costs and improve future performance.

Related Content

Three Good Reasons to Switch from Three- to Five-Axis Machining in Moldmaking

Five-axis machining technology is a great tool in the moldmaker toolbox.

Read MoreHow to Manage Wall Thickness Changes in Your Mold Design

To ensure even filling and cooling, consider wall section transitions, corners and fillets, ribs and bosses, lip and rim designs and CAE flow simulation software.

Read MoreHow to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreFour Micro Tooling Considerations

Issues involving gating, ejection, mold splits and direction of pull are of special concern when it comes to micro tooling.

Read MoreRead Next

Five Benefits of Integrated CAD/CAM

Integrated CAD/CAM software that combines CAD, CAM, electrode design and CMM programming capabilities in one system can save you time and effort in the following five ways:

Read MoreIn Simulation We Trust

Are you taking full advantage of simulation technology?

Read MoreThrive on New Market Opportunities

How the right manufacturing engineering software enables diversification.

Read More