Throwback Thursday: Liquid Silicone Rubber Molding Simulation

According to this week’s Throwback Thursday article titled “Liquid Silicone Rubber Molding Simulation”, which was published in January 2011, the use of simulation technology for LSR molds can be quite advantageous.

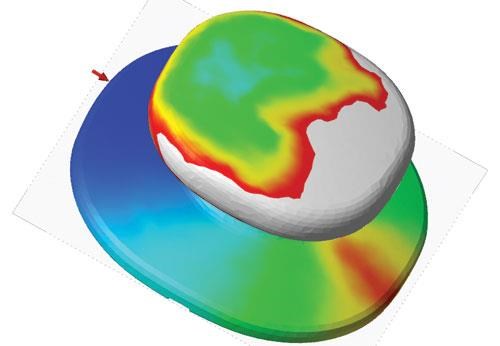

Determining the number of gates and their location is a very important decision for the moldmaker, whether it is for conventional molding or for LSR molding.

There’s a lot of discussion about the use of simulation for plastic injection molding and not so much regarding its use with liquid silicone rubber molding. Part of the problem at the time was the lack of material data and formulations to help characterize LSR. Yet, according this week’s Throwback Thursday article titled “Liquid Silicone Rubber Molding Simulation”, which was published in January 2011, the use of simulation technology for LSR molds can be quite advantageous.

Click here to access the article, and look for discussions on using simulation to:

- Find the best gate locations

- Eliminate premature curing during filling

- Detect high shear rates

- Determine pressure drops and identify air traps

- Optimize cycle time.

If you use simulation for LSR molding, please share how you’ve done it, and provide some findings as it compares to plastic injection molding simulation.

Related Content

-

How to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

-

How to Manage Wall Thickness Changes in Your Mold Design

To ensure even filling and cooling, consider wall section transitions, corners and fillets, ribs and bosses, lip and rim designs and CAE flow simulation software.

-

Tolerancing in Mold Design, Part 2: Using GD&T to Address Conventional Tolerancing Issues

Mold designers can achieve a single interpretation of workpiece functionality when following the American Society of Mechanical Engineers Geometric Dimensioning and Tolerancing standard.