2017 Leadtime Leader Awards Winner: Graphic Tool Corp.

Leadership changes set this mold manufacturer on a path of renewed purpose, fueled by data-driven, lean methodologies and deliberate, quality-controlled production.

If you’ve used products such as aerosol sprays, cosmetics or medications, you’ve probably used products packaged in containers for which Graphic Tool Corp. built the molds. Such molds are extremely precise, often holding tolerances of 0.0001 inch, and the team at Graphic Tool is proud of having won the trust of customers who are among the largest original equipment manufacturers in the world.

“A lot of companies build molds. We like to say that we build the Formula-One-race-car type of molds,” says Donald Smith, president/general manager. He credits the company’s success to carefully crafted core values based on a mission of meeting the needs of clients and fellow team members, plus continuous improvement of processes, products and services. Graphic Tool has championed the continuous improvement philosophy for more than a decade. These qualities helped the company win top Leadtime Leader honor for 2017. The company was a recognized Leadtime Leader Award honorable mention in 2003 as well, which underlines its penchant for continuous improvement.

Founded in 1982 by Richard Burman and employing 32, Itasca, Illinois-based Graphic Tool operates out of a modest, 17,500-square-foot building. From the beginning, the company’s philosophy has focused on using the latest equipment and technologies to ensure profitability, even during economic downturns, without necessarily enlarging its team. This “doing more with less” way of thinking served the now-retired Burman well over 34 years, Smith says, because it facilitated lean manufacturing processes through automation, which helped Graphic Tool win jobs despite low-cost overseas competition and the ever-present skills gap. “Rich also recognized the difficulties that high-cavitation molds would pose for offshore suppliers, and in the early 2000s, his team began pursuing this market segment in earnest,” he says. High-cavitation molds now constitute more than 60 percent of the company’s production.

In 2013, Burman initiated the process of selling his business to an equity group, namely Albion Investors and Isleworth Capital. The former is now the majority owner. During the transition of ownership, Graphic Tool recruited Smith, who was the global engineering manager at Rexam Mold Manufacturing at the time, because of his history with a large, corporate entity and his experience running a process-driven, lean organization. In March 2014, Burman finalized the sale of the company, and a new management team was established with Smith at the helm.

“We set out to build a strategy around what kind of company we wanted to be, and using lean methodologies, we process-mapped our mold-building procedures to uncover where the waste and/or bottlenecks were, and invested in the equipment and process training needed to alleviate them. We also reorganized the plant floor for better workflow in a cellular environment,” Smith says. Graphic Tool now has work cells for CNC machining, grinding, EDM, turning, and a finish-grinding/assembly area, all of which helps work flow much better through the shop, he says. However, Smith asserts that this is all still very much a work in progress, adding, “These process maps are living documents. Continuous improvement never ends. It’s the relentless pursuit of perfection.” Today, the company primarily seeks customers whose molds will be in production for at least 15 to 25 years. “We won’t turn anyone away, but our sweet spot comprises not custom molders, but OEM companies that have the financial wherewithal to purchase molds built at a very high level of quality,” he says.

In addition to molds for caps, closures and other threaded parts, the company concentrates on designing and building high-cavitation tooling for beauty products, dispensing products and packaging. Complete interchangeability of mold cavities and cores to reduce customers’ downtime when spare parts are needed is the hallmark of its capabilities.

Approaching Business Deliberately

Smith says it was evident that, while successful, Graphic Tool was being run as a traditional mold shop prior to the acquisition by Albion Investors, with little in the way of operational data to measure or set a baseline. He says it was critical to the future of the company that it adopt a new operations mindset, defined by new mission and vision statements that speak to its newfound lean methodologies and continuous improvement philosophy, and that it begin, as he puts it, “running a metrics-driven business that just happens to build molds.”

As a certified Lean Black Belt and Six Sigma Green Belt, Smith utilized the Six Sigma process (define, measure, analyze, improve and control) and completed a SWOT analysis in June 2014. “We defined our strengths and weaknesses, as well as opportunities and threats, and that gave us our focus on what customers we wanted to work with,” he says. The shop invested in JobBOSS enterprise resource planning software, and Smith says he utilized the business guide “Five Steps to Your Manufacturing Dream Shop” that came with it as an additional guideline. “Its five steps, or fundamentals, are uncomplicated and get right to the point,” he says. They are: 1) Understand your current business state and (re)evaluate its core competencies; 2) maintain your business agility; 3) focus on (re)building long-lasting customer and supplier relationships; 4) improve efficiencies from the front office to the shop floor; and 5) collaborate and network with your business peers.

By January 2015, Graphic Tool had a strategic business plan. “From that plan, we developed our key performance indicators (KPI) so we can track and measure how well we are meeting our business objectives,” he says. Those KPIs include resource capacity versus actual hours worked and unattended machining hours achieved as a percentage of direct hours. All the KPIs have target numbers, and Smith says he reviews them weekly with the team, along with year-to-date statistics. These are then used for budgeting purposes going forward. He says more KPIs will be added in the future, including those that track overall equipment effectiveness (OEE) and machine availability (actual machine production time as a percentage of machine availability), in addition to machine performance and quality metrics.

“It’s about changing the culture of how people work,” he explains. “We’re being proactive by flying our plane using instruments versus flying by the seat of our pants.”

Championing the Process

From design and engineering through programming and production, Graphic Tool employees are encouraged to “champion the process” by streamlining every step to make it more efficient and then marrying these lean processes with strict quality control. As a result, EDM work cells (two wire and five sinker) with automatic/robotic electrode changers and automated machining cells require only two operators and provide 24/7 machining capabilities, cutting lead times, Smith says.

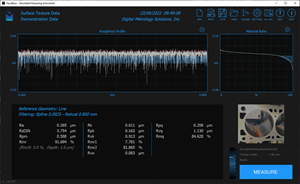

Constant in-process control monitoring is required for all electrodes, meaning electrodes are 100-percent inspected prior to burning using one of the company’s two Brown and Sharp Micro Excel coordinate measuring machines (CMMs). Smith says the design of the electrodes themselves is based on planning meetings that include everyone who will work on a particular mold. When the electrodes are pulled, an inspection routine designed for the CMM is executed. Radio frequency identification (RFID) chips are loaded in the EDM setup and contain operational data intended to virtually eliminate errors in setup and machine settings. “It’s a tightly controlled process,” he says. This, along with comprehensive steel certification documentation (critical part dimensions), benefits Graphic Tool’s customers by speeding the mold validation process and enabling faster release of their products to market, Smith says. “It’s a sharp contrast to the way things used to be run,” he says.

Instead of shouldering the lion’s share of the responsibility for taking a job from concept to completion, project leaders now work much more collaboratively with the rest of the team. Smith says having more sophisticated equipment on the shop floor facilitates a less hands-on approach and a greater focus on “the big picture.” “Perhaps more importantly,” he says, “standardized procedures for quoting, designing, engineering and programming minimize lead times and ensure consistent quality from job to job, unlike before when each individual moldmaker would lead a job his own way. The people do not drive the processes; the processes drive the people.” He likens it to a team using a “playbook” with very detailed steps. There’s a plan with expectations (planned hours), and everything is monitored according to that plan, he says.

Today, customers can expect lead times of four to six weeks on one- and two-cavity molds, six to 10 weeks on four- and eight-cavity molds, 10 to 14 weeks on 16- to 24-cavity molds, 12 to 16 weeks on 32- to 64-cavity molds, and 16 to 20 weeks on 64-cavity and larger molds. Smith says these lead times are 10 to 20 percent shorter than those the shop could previously achieve. “We can now see when and where bottlenecks may occur, and provide alternatives such as outsourcing,” he says.

Optimizing Customers’ Outcomes

In addition to efficiently and precisely executing each process required during mold design and build, Smith says Graphic Tool’s program management and engineering team works closely with customers to verify that part designs are optimal for manufacturing before any chips are made. This involves more than simply evaluating part specification and appearance, he says. Rather, engineers start with evaluation of customers’ production processes, followed by part-design evaluation and assistance, state-of-the-art 3D solid modeling via Siemens NX CAD/CAM software and, if required, mold flow analysis. The shop also makes available a single-cavity pilot-mold process in which concept validation occurs concurrently with building of the production mold to reduce lead times. Molds designed to consolidate parts and eliminate secondary assembly operations are also possible. Smith also says all molds are designed and built for guaranteed component interchangeability from cavity to cavity so that if a spare part is needed the customer does not have to ship the entire mold back to the shop. Graphic Tool maintains all mold data on the molds it builds and can provide a replacement part that will fit precisely. Reverse engineering of an existing mold, even one that was not built by Graphic Tool, is also possible. This methodology has been used to reduce existing cycle times for molds that were built as much as 20 years prior using older technology. The shop has also been working with one of its global customers on a cycle-time-reduction initiative that uses conformal cooling, Smith says.

Once a project is launched on the shop floor, the program management team monitors every phase of the mold build and customers receive weekly progress reports showing actual hours as a percentage of planned hours worked during each stage of a job; percentage of completion; and a corresponding chart illustrating exactly where a job is on the schedule, based on the plan.

Smith says machine tools are kept “current.” For example, a DMG MORI DMC 75V-Linear five-axis machining center with a 60-tool toolholder carousel and FANUC R-2000 robot with multi-pallet system enables five-sided, lights-out machining with just one setup (see equipment list sidebar on page 12). However, machines aren’t the only tools that keep Graphic Tool on its A game, he says. Its customized quoting system is comprehensive and accessible, enabling a quote to be generated exponentially faster than most and accurately as well, he says. Developed by Smith over the course of about 20 years, this system can generate three quote styles (ballpark quotes, quotes summarized from ratios based on historical data and quotes detailed to task level where a detailed plan is created) using templates based on families of products that Graphic Tool specializes in building molds for. “The system was created because there was really nothing available on the market that allowed us to refer back to previous jobs over a period of time,” Smith says. “Quoting is often a hated process, because it’s an incredibly inefficient one. But this system provides a way to quote faster and more accurately based on experience and data in an environment where we are constantly competing, so time is used more productively, historical data is being validated and the system is adaptable.”

Smith says the quoting system is in the process of being integrated with the company’s home-grown project scheduling software. The goal is to automatically populate project data from quotes into the software, generating forms that detail shop tasks, engineering tasks and mold base work, including cost of materials and labor costs. That data would then be input into the shop schedule as quickly as possible. This will eliminate having to repeat data inputs, thus saving time and reducing errors, he says. If customers change specifications, new quotes and schedules can be quickly generated without having to begin from scratch.

“By using this methodology, the software provides us with data that helps us make educated business decisions, which is at the absolute core of our business,” Smith says. “If we are seeing a slow period in the future, then we can easily calculate how low we can go, without hurting our business. Conversely, it will also help knowing what we can potentially sell a mold for, by maximizing our margins. The system is visual and adjustable. What-if scenarios can easily be entered to understand the impact of a customer change request. Finally, and most importantly, it helps us understand how we can improve and target our overall profitability.”

Training Future Leaders

Each member of Graphic Tool’s management team, which includes plant manager Tim Bandurski and planning and scheduling manager John Gallo, has at least 20 years of experience with injection mold manufacturing. Even the chief financial officer, Jerrie Delaney, has worked in the industry for more than 20 years. Smith says that, for the types of molds the company builds, it’s essential to have such highly qualified leaders, but he is also keenly aware of the need to recruit and train the next generation of leaders to ensure continuity.

“We are continuously investing resources to help the community build stronger training programs by offering outreach programs to the local schools, summer internships, partnerships with the local trade associations and more,” Smith says. For example, in 2015, the shop offered its four-week “Manufacturing Fundamentals” internship to a student at Streamwood High School in Streamwood, Illinois. The student worked four full days a week, creating journal entries about what he learned each day. Topics included various mold types, lean manufacturing, engineering processes, and even quoting and finance.

Smith says the shop facilitates employee retention with a review process designed to promote personal growth. “We set objectives, together with each employee, so that they are agreed on and ultimately measured based on job performance over a period of time,” he explains. Employees know exactly what is required of them and are aware of various opportunities for growth and advancement within the company, including specific courses to improve job performance. Graphic Tool also provides “guiding principles” by which every employee is asked to abide. They are: “Go home safely every day (safety first);” “do the right thing even if no one is watching;” “carry a winning attitude and embrace change;” “communicate openly and professionally;” “always perform at your best;” and “do what you say you will do.”

Another personnel development tool is that, for every senior management position in the company, there is one person who is or will be mentored on that aspect of the business. Smith says mentoring began in the engineering and production scheduling/planning departments in 2016, and candidates have been chosen for mentorship in finance and quoting and program management areas beginning later this year. Seven of the company’s 32 employees are younger than 30 years of age, including two moldmakers in training and two apprentices. “We’re proud to say that these seven young men are the future of Graphic Tool,” Smith says.

To see the video highlighting Graphic Tool's “pursuit of perfection,” visit short.moldmakingtechnology.com/2017lla.

Related Content

Software Strategy for Automated Mold Inspection

Consider inspection software with a CAD/CAM platform that supports model-based definition, works with all CAD files, and drives all fixed and portable CMMs.

Read MoreHow to Harness 3D Scanning for Mold Tool Repairs

3D scanning supports the repair of molds with no history, drawings or design files.

Read MoreThree 3D Scanner Investment Considerations

Mold builders taking advantage of laser and software advancements for portable 3D measurement tools can reduce inspection and measurement times.

Read MoreWhat Does Surface Roughness Mean in Moldmaking?

To improve mold performance, reduce wear and produce high-quality molded parts, mold builders must understand surface texture and how to properly measure, analyze and control it.

Read MoreRead Next

Graphic Tool: Concurrent Engineering Generates Quick Mold Builds

Using the latest in technology and equipment concurrently adds up to sales aplenty - and an Honorable Mention in MoldMaking Technology magazine's Leadtime Leader competition.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More