Analysis

What Is the ROI Of 3-D Scanning?

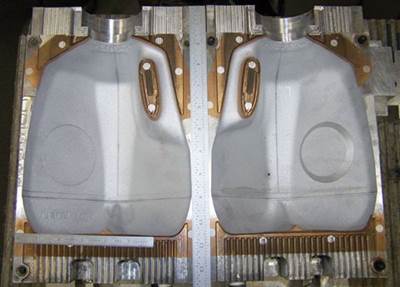

A moldmaker wanted to re-qualify used molds to see if they needed refurbishing, and if so, where to make the corrections.

Read MoreMeasuring the Effectiveness Of Your Mold Machining Ops

A review of the shortcomings and solutions to OEE challenges.

Read MoreMeasuring Massive Molds

When working with massive molds, the penalties of rework are greater than those of smaller sized molds.

Read MoreFacing the Quality Challenges of Large, High-Precision Tooling

Advanced off-line inspection software speeds up mold manufacturing and assembly for aerospace giant.

Read MoreAnalysis of the Additive Manufacturing (AM) Industry Worldwide, Part I

After more than two decades of research, development and use, the additive manufacturing industry continues to expand with the introduction of new technologies, methods and applications. Additive processes have had a tremendous impact on design and manufacturing, and this impact will continue to grow in the coming years.

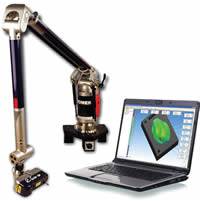

Read More3-D Laser Scanning Opens the Door to Inspection And Reverse Engineering for Moldmakers

Next-generation scanning technology precisely captures large and small molds.

Read MoreDetecting Water Flow Restrictions

A look at how taking the time and data to analyze a mold problem will help you repair it right—and permanently—the first time.

Read MoreMeasuring CAD Skills Gives Greater Efficiency

CAD is at the heart of modern manufacturing and moldmaking. But just how good are people at using the CAD tools they are given? This article reviews the options for assessing the skills and training needs of CAD users.

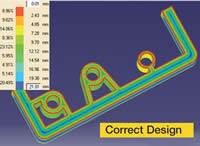

Read MoreBenefits of Using the Right Measurement Tool

How to accelerate design review with the right measurement tool and what to look for in the tools you select for measurement and checking of thickness on 3-D models.

Read MoreFive-Axis Inspection for Moldmakers

Does five-axis inspection offer similar benefits in speed and accuracy for moldmaking operations?

Read More