Measuring CAD Skills Gives Greater Efficiency

CAD is at the heart of modern manufacturing and moldmaking. But just how good are people at using the CAD tools they are given? This article reviews the options for assessing the skills and training needs of CAD users.

Inefficient use of CAD technology in industry wastes millions of dollars each year. It is vitally important that businesses have the tools to quantify the skills of members of staff using CAD to make sure that they are right for the role in question, and that the role in question is right for them. Companies need to ensure the optimum performance of technical staff to deliver crucial workloads accurately in a highly pressurized environment.

Many companies today employ CAD technology on multiple projects at the same time, often across a number of offices, even across several locations worldwide. This combined with the trend toward outsourcing and off-shoring of production information work, means it is vitally important to be able to benchmark the performance of teams using CAD software to maintain high standards.

It is essential that manufacturing firms are able to quantify the performance of CAD users, particularly when planning training or recruiting new staff. More enlightened firms are responding to this need by implementing a roadmap to enable a better return on their considerable investment in CAD technology.

The Need to Quantify the Skills of Staff Using CAD

In sport it’s always easy to see who the star players are, and who should be the last ones to be picked. Unfortunately it’s not so easy in the world of CAD, where all you see are bodies sitting in front of monitors and keyboards, clicking away all day. However, designing using CAD software is no different from any other activity in life—some people are better at it than others, and everyone can do better with the right coaching.

Fortunately there are a number of very cost-effective, field-proven methods for firms to measure CAD skills. Examples include the following:

Multiple Choice Questionnaires

The simplest form of CAD skills assessment is the multiple choice questionnaire. There are a number available on the Web or you can develop your own (e.g., www.ramsaycorp.com or www.academix.com).

In-House CAD Test

Many firms develop their own in-house CAD test. This is usually more relevant when recruiting new staff, and of less value in identifying the training needs of existing employees.

Live Skills Drafting

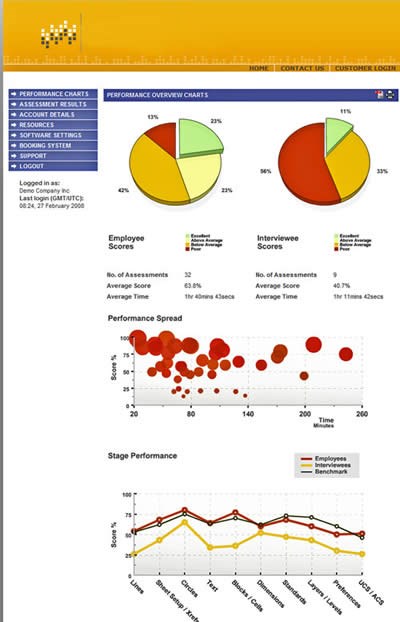

CAD skills assessment software that assesses 10 core skills by setting exercises in live CAD software. The assessment is automatically marked, and a certificate produced. The results can be compared against the benchmark of a database of 10,000 assessments. The software provides a training needs recommendation report and feedback on

performance.

Professional Certification

Independent bodies offer accreditation exams in CAD (e.g., American Design Drafting Association, www.adda.org; European Computer Driving Licence, www.ecdl.org).

Vendor Certification

A mix of simple multiple choice and task-based exercises, the aim of certification is to prove professional competence in use of a specific version of CAD software. There are certification programs for Autodesk, SolidWorks and Solid Edge, among others.

Training

Once the CAD users training needs have been identified, the next stage is to deliver the required training. Blended learning is becoming the favored way to improve CAD skills. Using a mix of classroom training, mentoring, lunch-and-learns and e-learning materials has been shown to deliver the required support and knowledge to the CAD user at the right time, when they need it most.

Taking advantage of new technology there are effective and affordable video-based, self-paced training materials that can be used in the workplace (e.g., www.cadlearning.com and www.solidprofessor.com).

Return on Investment

Skills assessment is not expensive. Multiple choice tests range from around $20 to $30 per person. An annual subscription can start for under $700 and provides for unlimited assessments. Vendor Certification exams range from $50 to $500, depending upon the level, and self-paced e-learning CDs from start at under $300.

Of course, most of these assessments and tests available are not specifically written for the moldmaking industry, but what they do check is that the underlying CAD skills are in place to underpin the mold design process.

Studies have shown that an improvement in accuracy and productivity of only a few percent will pay for the investment a firm makes in CAD skills assessment and training. The reality is that every firm can do better in CAD productivity. There are proven products available to measure CAD skills and identify training needs, and cost is no longer a barrier.

![]()

Related Content

How to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

Read MoreHow to Select a Mold Temperature Controller

White paper shares how cooling channel analysis, which collects maximum pressure drop, total flow rate and heat dissipation, eases the performance evaluation of mold temperature controllers.

Read MoreCAM Code Is Key to Precision Mold Machining

The intuitiveness of Mastercam’s CAD/CAM interface streamlines training and advanced programming for intricate fishing tackle products from Venom Outdoors.

Read MoreThe In's and Out's of Ballbar Calibration

This machine tool diagnostic device allows the detection of errors noticeable only while machine tools are in motion.

Read MoreRead Next

Toolmakers Will All Have College Degrees

Anchor Glass Container Corporation’s Mold Division plans to stay competitive with a well educated workforce.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More