Analysis

Improving Quality to Increase the Bottom Line

Prevention cost is one of the most significant elements of the cost of quality. When developing plans for reduction of quality expenditures, it is critical to analyze the various prevention costs during the product launch phase with a shop floor management system or ERP solution.

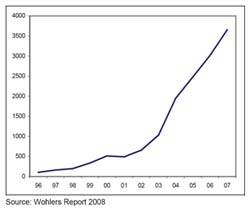

Read MoreThe Impact and Evolution of Additive Fabrication

SAn executive summary of the annual Wohlers Report that provides quantitative and qualitative analysis on the additive fabrication industry worldwide.

Read MoreBadgering Mold Variability with On-Machine Gaging

Using unique on-machine metrology software helps to nail down injection mold machining consistency.

Read MoreOptimizing Plastic Injection Mold Materials with FEA

Tooling cost reduction can be achieved with up-front engineering via company collaboration and simulation technologies based on finite element analysis.

Read MoreWhy You Need to Inspect the Part to See the Mold

In the simplest terms, a good mold is one that makes good parts. When your customer is making good parts, no one questions the mold. It’s when the parts are not meeting spec that the mold—as one of the main elements of the molding system—is called into question. In these situations, one common proposal is to measure the mold to ensure that it conforms to the designed dimensions.

Read MoreMeasure Your Success for Rough Milling Improvements

In moldmaking, most applications still follow the traditional two- or three-phase process consisting of rough/pre-finish/finish, in order to hold tolerances. The following article will focus on the first phase of operations—the roughing phase—and how shops can improve rough milling applications with new strategies and cutting tools.

Read MoreMoldmaker Uses a Solution-Based Approach To Mold Flow Analysis

MoldFlow consulting firm assists mold shop as it approached a complex molding program for its customer, Cessna Aircraft Company.

Read MoreDetermining Maximum Mold Cycle Counts

Ongoing data collection and visual inspection of tooling and parts is the only method that will allow you to balance maximizing tooling life, production capability and mold reliability.

Read MoreDo Eight Years Matter?

Data and analysis results of a North American plastics industry study on the mold manufacturing industry call for change.

Read MoreFusion Process from Abroad Increases Mold Performance

A select laser melting process has been developed overseas involving the fusion of a metallic powder by a scanning laser to produce complex, intricate 3-D parts that could impact the U.S. moldmaking industry

Read More