Analysis

CT scanning: A Differentiating Factor

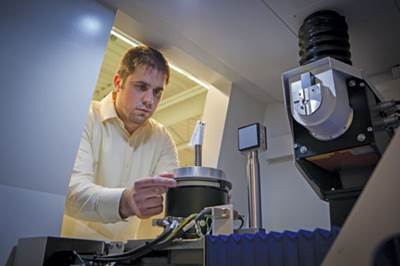

NyproMold finds its growth in differentiation—including using CT scanning to look through parts with an accuracy of 5 to 7 microns, obtaining information that can speed the mold manufacturing process.

WatchLean Initiative Leads to Automated Metrology Solution

This cell has helped us reduce costs in the electrode manufacturing area—realizing a 26-month return on investment, which makes the justification for another system that much easier.

Read MoreMoving from a Trickle to a Trend

I came across an article sharing a simple plan for how to propel the reshoring trend forward ... some very familiar concepts: (1) A more educated workforce to fill skilled labor gaps, and more Americans interested in careers in manufacturing at all levels; (2) More extensive use of automated assembly processes to limit the labor input of production; and (3) Tools to help companies evaluate their true total cost of ownership (TCO) when offshoring to model all costs and risks. It does seem like reshoring is getting a lot of play nowadays ... but I'm not complaining ... it's a good thing!

Read MoreTotal Cost of Ownership (TCO) Analysis Works for Everything

At the recent amerimold 2012 show in Novi, MI, the opening keynote speaker was Harry Moser. For those of you not familiar with Mr. Moser, he is a retired executive from the machinery industry who now devotes his energies to the Reshoring Initiative. In short, Harry is trying to bring mold and die manufacturing back to the U.S. His argument is based on the concept that when you consider ALL of the costs involved in manufacturing a plastic part (not just the price of the mold), America is more competitive than places like China for many types of parts. Harry has developed a nifty little spreadsheet program that assists mold buyers in calculating the wide range of costs that they will incur when they choose to manufacture a part. This analytical process of identifying and evaluating all of the costs—now and in the future--goes by the name of Total Cost of Ownership (TCO), and moldmakers should also master this process.

Read MoreVideo: CT Scanning for Mold Inspection

Moldmaker NyproMold describes its experience using computed tomography (CT) scanning to validate precise injection molds.

WatchInspection Services Help Moldmaker Push the Envelope

“As technology moves forward, to be able to design and produce these parts you must be able to prove to the customer, through your inspection results, that they will work.”

Read MoreMicro Inspection at Matrix Tooling

Various inspection and measurement resources help a moldmaker produce tooling for tiny molded parts.

WatchNyproMold Adds CT Scanning to Its Metrology Capabilities

NyproMold (Clinton, MA) highlighted its use of CT scanning as it adds a suite of innovative services to its industrial metrology capabilities.

Read MoreInjection Molding Analysis Ahead of Tool Production Removes Guesswork From Mold Manufacture

Patented injection molding analysis ahead of tool production, ensures that a number of components in a water powered rock drill are manufactured to the degree of absolute precision required by mining operations around the world.

Read MoreTake a Second Look at Production Aluminum Tooling

One moldmaker has put aluminum tooling to the test and advises a second look for your high-volume automotive applications because it can address your quality, cycle time and cost challenges.

Read More