Analysis of the Additive Manufacturing (AM) Industry Worldwide, Part I

After more than two decades of research, development and use, the additive manufacturing industry continues to expand with the introduction of new technologies, methods and applications. Additive processes have had a tremendous impact on design and manufacturing, and this impact will continue to grow in the coming years.

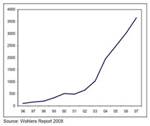

Twenty-nine system manufacturers and 65 service providers worldwide responded to a survey. These 94 companies represent an estimated 5,000+ users and customers and provided information based on their knowledge of them. According to the survey, companies are using AM technology increasingly for functional modeling, the number one application of the technology (see chart). Meanwhile, direct part production has grown from almost nothing seven years ago to become the second most common application of AM technology.

System Manufacturers

In 2008, several companies introduced new AM systems to the market. EOS (Germany), Objet Geometries (Israel), Mcor Technologies (Ireland), MTT Technologies Group (England), and three U.S. companies—Optomec, 3D Systems, and Z Corp.—introduced new machines.

In Q4 2008, chemicals giant Huntsman Advanced Materials (Switzerland) surprised many when it announced the development of an entirely new additive manufacturing process and machine. In early 2009, Stratasys introduced the $14,900 uPrint system based on FDM technology. ReaLizer (Germany) and A1 Technologies (England) also introduced systems in 2009.

Service Providers

Service providers have offered part building services to organizations that were reluctant to invest in a new technology or could not justify the purchase of a system. Many of the modeling services provided in the 1990s are largely being done today by in-house systems, such as relatively low-cost 3-D printers. The percentage of service providers adding capacity in 2008 was lower than in 2005 and 2006, yet it increased from 2007 levels.

A new type of service provider is developing that is targeting consumers. One of the best examples is Netherlands-based Shapeways, a company that is a part of the Philips Electronics’ incubator program. The relatively new company allows customers to upload a design and then Shapeways manufactures it using AM and ships it to them. This may sound similar to working with a conventional AM service provider. The difference is that Shapeways is focused on the consumer market. Prices range from a few dollars for a ring or key chain to $100 for a semi-custom lamp. Larger pieces can cost more.

Part II of this analysis will cover additive manufacturing around the world, direct part production and the industry’s future.

Related Content

-

MMT Chats: 5 in 5 with Best Tool and Engineering

MoldMaking Technology Editorial Director Christina Fuges reveals 5 best practices for improving efficiencies within shops...in 5 minutes. Our guest is Joe Cherluck, President of Best Tool and Engineering in Clinton Township, Michigan.

-

What is Driving Mold Lifecycle Management Digitalization?

OEMs are looking to partner with suppliers to share and track data across the supply chain for advanced intervention and process management.

-

The Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.