Haimer USA

134 E Hill St.

Villa Park, IL 60181 US

866-837-3265 | 630-833-1500

haimer@haimer-usa.com

haimer.com

IS THIS YOUR COMPANY?

As Seen On MoldMaking Technology

Haimer USA Supplies the Following Products

- Balance Machines

- Balancing Equipment

- Cutting Tools

- End Mills

- Hard Milling

- High-Feed Milling

- Noncontact Measurement Systems

- Optical Measuring Systems

- Probes

- Tool Management Systems

- Toolholders

Editorial, News, and Products

-

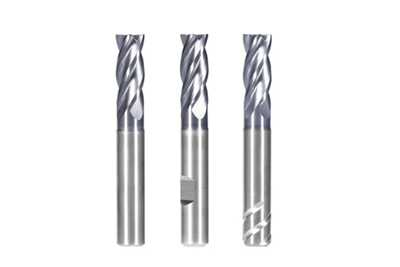

End Mill Delivers Maximum Cutting Volume for Steel Materials

Haimer USA highlights the upcoming Panther Mill, its latest innovation in high-performance cutting tools to benefit the machining processes beginning in 2025.

-

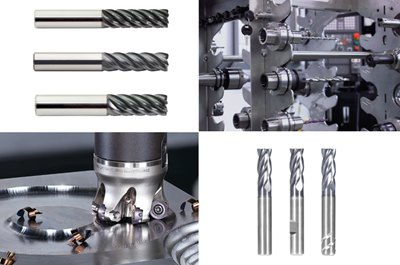

Mills Line, Cutting Tool Management System Tailored to Machining Optimization

IMTS 2024: The Haimer Mill line, with tool options suited for ramping, drilling, milling and slotting, as well as the WinTool and ToolBase systems, aim to advance machining precision and management.

-

Innovative Technology for Your Mold Shop at IMTS 2024: Part 1

MoldMaking Technology highlights a variety of innovative applications featured this year at IMTS 2024. From software solutions to new machines and services, dive into this comprehensive guide to best equip your mold shop.

-

End Mills, Drills, Inserts and More for Mold Building Needs

This list of cutting tool-related products that MMT editors have recently published provide readers a good look at what is being offered in the industry for their everyday operations.

-

Cutting Tools Portfolio Caters to High Machining Demands

The Haimer Mill line offers a variety of entry-level cutting tools for roughing and finishing that deliver precision, reliability and efficiency.

-

November Product Highlights

In this most recent roundup, MMT continues to present the breadth of new or proven technologies that target the moldmaking industry, from cutting tools to software to molding-related products, that have been shared this month.

-

Shrink-Fit Machine Features Integrated Cooling

Power Clamp Air i4.0 Eco by Haimer USA provides smooth and clean cooling of all kinds of toolholders or collets by air, without dirt and water residue.

-

Moldmaking, the Relentless Pursuit of Innovation … Oh Yeah!

Innovation was at the root of the presentation lineup for the 2023 MoldMaking Conference, which included a heavy focus on automation, collaboration and communication, as well as mold design, talent development, reshoring and sustainability.

-

Cutting Tools: Technology to Make Your Process Easier

Having the right cutting tool technology for moldmaking is a crucial component for efficiency and cost-effectiveness.

-

Last Chance to Get Your Seat at MoldMaking Conference 2023!

Next week the moldmaking community comes together in Minneapolis for two full days of learning. It’s not too late to register to reserve your seat!

-

MoldMaking Conference Right Around the Corner!

This year features a dynamic lineup of experts focused on technical innovations, business strategies and workplace development initiatives for mold manufacturers. See the full agenda and register today!

-

MoldMaking Conference Session Spotlight: Tooling Success

Want to learn about best practices in program management or the mold builder's role in new product development or a remote validation process?

-

MoldMaking Conference Session Spotlight: Software

Want to learn how to leverage CAD/CAM to streamline your moldmaking process or how to engineer cooling efficiency?

-

MoldMaking Conference Session Spotlight: Data

Want to learn about digital workflows in mold design or ERP or global mold monitoring and asset management or the impact of tooling digitalization?

-

MoldMaking Conference 2023: Education, Collaboration, Innovation, Discussion - Early Bird Discount Ends July 31st!

The moldmaking community will gather on August 29-30 in Minneapolis, Minnesota for a two-day technical program co-located with the Molding Conference. Here is a sneak peek at the sessions.

-

MoldMaking Conference Session Spotlight: Workforce Development & People Operating Systems

Want to learn what a people operating system is and what's really holding manufacturing back?

-

MoldMaking Conference Session Spotlight: Mold Design

Want to learn about collaborative mold design or a plan to reduce back-end troubleshooting?

-

MoldMaking Conference Session Spotlight: 3D Printing

Want to learn about hybrid tooling inserts or the current state of 3D metal printing?

-

MoldMaking Conference Session Spotlight: Automation

Want to learn how to use automation to solve the "productivity puzzle" or how to choose between “lights out” or “unmanned” automation or how to implement a three-phased automation approach?

-

MoldMaking Conference Session Spotlight: HOT TOPICS

Want to learn how to successfully reshore tooling or how to play a part in sustainability or how to take advantage of the changes to the R&D Tax Credit?

-

MoldMaking Conference Session Spotlight: Presenters Return to Give Progress Report

Want to learn about a strategy to create a highly effective and scalable moldmaking business or the impact of mold digitalization?

-

Next-Level Mold Manufacturing Highlighted at MoldMaking Conference: Data, Communication, Collaboration

Owners, engineers, operations managers, toolroom managers, apprentices and more left the MoldMaking Conference with a list of real-world tips, fresh ideas and new connections to bring back to their teams.

-

VIDEO: Applying Industry 4.0 to Cutting Tool Solutions

Craig Schepers, Regional Sales Manager for Haimer, shares tips with MoldMaking Technology’s Editorial Director Christina Fuges, on how the company applies Industry 4.0 to its cutting tool solutions. They also discuss how to adapt to customer needs in a post-COVID world.

-

Are You a Next-Level Mold Manufacturer?

Introducing the MoldMaking Conference for the next-level mold manufacturer because moldmaking has moved beyond art and craft to science with technology advancements aimed at engineering and building a better, more cost-effective mold.

-

The MoldMaking Conference: General Sessions on Tooling Digitization and Design Apprenticeships

Here we spotlight the General Sessions of the MoldMaking Conference on November 8 & 9 in Charlotte, North Carolina.

-

The MoldMaking Conference — All About Next-Level Mold Management

Here we spotlight the Manage block of sessions of the MoldMaking Conference on November 8 & 9 in Charlotte, North Carolina.

-

The MoldMaking Conference: All About Next-Level Mold Maintenance

Here we spotlight the Maintenance block of sessions of the MoldMaking Conference – for the next-level mold manufacturer – November 8 & 9 in Charlotte, North Carolina.

-

IMTS 2022 in a Flash

With this still being the month of IMTS, I thought I’d highlight some of the technology mold builders have expressed growing interest in and are actively investigating, and what was on the show floor.

-

The MoldMaking Conference: All About Next-Level Mold Building

Here we spotlight the Build block of sessions of the MoldMaking Conference on November 8 & 9 in Charlotte, North Carolina.

-

Get Ready for IMTS With These Mold Manufacturing-Focused Exhibits

It’s always important to visit IMTS with a general plan of action. MMT editors help familiarize you with several machining, software, cutting tool, EDM and mold repair innovations that will be exhibited and are geared toward moldmaking.

-

Modular Milling System for Carbide Tool Heads Achieves Maximum Cutting Depth

In addition to highlighting Industry 4.0 versions of its machines, Haimer USA is featuring its Haimer Mill solid carbide end mills and Duo-Lock modular system at IMTS 2022.

-

MoldMaking Conference: All About Next-Level Mold Manufacturing

Next-level mold manufacturing is dependent upon accurate, repeatable and efficient technologies, processes and talent when it comes to designing, building, maintaining, repairing and managing molds. It is with this focus in mind that we are launching The MoldMaking Conference on November 8-9 in Charlotte, NC.

-

If You're Reading This Then, You Already Know ...

… that a mold matters. You know that a mold is the heart of the injection molding process. You know that a mold is not just a piece of steel; it’s a machine. That is why we launched MMT and now the MoldMaking Conference!

-

Time for Tooling to Get in the Game: Submit to Hot Shots Today

MoldMaking Technology joins Plastics Technology in calling all molders and mold builders to enter the injection-molded parts competition to be held at their co-located events in November 2022.

-

Workhorse Shrink-Fit Machines Yield Repeatability

Omega Tool Inc. switched to a toolholder/shrink fit system for better quality, improved repeatability and longer cutter life for its ultra-precise mold machining.

-

“Molds Make a Difference” at the Plastics Technology Expo

That was the sentiment of every person who came up to the MoldMaking Technology booth during last week’s Plastics Technology Expo to grab their giveaway “Molds Make” t-shirt after working the aisles seeking technology and process solutions and making new business connections.

-

Haimer PTXPO Spotlight

Haimer discusses the upcoming Plastics Technology Expo (PTXPO) March 29-31

-

Technology Roundup: Selecting the Right Cutting Tool

Tool up with new product offerings from Iscar, Tungaloy, Horn, Walter, Haimer, Union Tool, YG-1 and other suppliers.

-

Amerimold 2021 Post-Show Flashback: Build

MMT looks back on the return of an in-person Amerimold in September after a year-long pandemic.

-

Toolholder System Ensures Highly Accurate Clamping for Complete Pull-Out Protection

Haimer USA invented Safe-Lock for high-efficiency, dynamic milling strategies, an EDM form in a shrink fit holder, with grooves on the tool shank for optimal engagement.

-

Open Mind Technologies, Haimer Join Forces to Five-Axis Machine an Aluminum Panther

Open Mind provided its hyperMILL CAM software and Haimer its flour-flute cutter and a linear five-axis machining center for a 20-inch panther to be showcased by the Augsburger Panther hockey team.

-

2021 Leadtime Leader Award Winner: Westminster Tool—Perseverance with a Plan

Westminster Tool’s latest commitment to the plan—investment in new technologies, processes and capabilities, workforce development/training and sales & marketing—helped them edge out this year’s competition.

-

Haimer USA Presents Power Clamp Nano NG i4.0 to Amerimold 2021 Attendees

The industry 4.0 shrink fit machine, specifically designed for shrink fit collets and small toolholders up to size HSK-A63, uses a horizontal shrinking process and ensures easy handling.

-

Haimer USA partners with Titans of CNC organization

The collaboration will focus on developing and delivering global, high-level manufacturing education to make machinists more efficient and productive.

-

Shrink Fit System is Industry 4.0-Ready for Shop Floor Communication

Haimer’s power clamp comfort i4.0 shrink fit system sets new standards regarding digital connectivity and communication of tools and machines for manufacturing.

-

Shrink Fit System Sets New Standards for Digital Connectivity

Haimer USA offers its Power Clamp Comfort i4.0 shrink fit system, which sets new standards regarding digital connectivity and communication of tools and machines for the new world of manufacturing.

-

Noteworthy News: Gratifying Get-Togethers

These industry events from DMG MORI, Haimer USA and Mazak Corporation provide exciting insights to latest technologies, as well as chances to meet and greet with friends both old and new.

-

HAIMER Looks Back at Event-Full Year

Haimer USA enjoyed greeting old friends, meeting new ones and spreading the word about precision machining at all of the events the company attended in 2019.

-

Makino Continues to Raise the Bar on Machining Technologies

Packed with information to help attendees advance moldmaking, and more, Makino’s Technology Expo shows the company’s commitment to its customers’ successes.

-

Machine Tool Builder Stresses New Strategies for Serving Moldmaking Customers

A new facility, new compact CNC and new customer service strategy for moldmaking customers is celebrated at Zimmermann open house.

-

2019 Technology Review: Cutting Tools

MoldMaking Technology’s 2019 Technology Review and Sourcing Guide offers some of the latest highlighted products and services from supplier companies from a variety of categories, including cutting tools.

-

i4.0 Integration Ensures Machining Success

Haimer USA hosted its annual Open House at its North American headquarters in Villa Park, Illinois, to showcase new i4.0 technology-related products that ensure machining success.

-

Shrink-Fit Machine Provides Integrated Cooling and Intuitive Software

Haimer USA will demonstrate its shrink fit machine, Power Clamp Sprint i4.0, at Amerimold.

-

Steven Baier Promoted to Vice President of Sales for Haimer

Steven Baier has been promoted to Vice President of Sales of Haimer USA.

-

VIDEO: How Can Moldmakers Benefit By Integrating Industry 4.0 into Their Machining Processes?

MoldMaking Technology Senior Editor Cynthia Kustush chats with Brendt Holden, president of Haimer USA, about Industry 4.0 and how moldmaking companies can embrace and prepare for using the tools of connectivity to increase machine utilization and overall productivity.

-

IMTS 2018: First Impressions

Do you remember your first IMTS? This year’s was mine. Here, I outline a few of my first impressions of the show.

-

Partnership Between Boeing Portland and Haimer Intensifies

This brings total OMIC R&D partners to 20 at its Scappoose, Oregon facility.

-

IMTS 2018: Process,Technology and Service Advancements

Advancements in automation and digital manufacturing took center stage during IMTS last week, but developments in additive manufacturing, cutter technology, machining solutions, simulation software, EDM, laser technology and customer service were other hot items.

-

Take a Creative Photo with the Haimer Marmot, Win a GoPro

Haimer is giving out its yodeling Haimer Marmot and asking IMTS attendees to think outside the box when taking creative photos of Marmot while in Chicago.

-

Scenes from Amerimold 2018 in Novi, Michigan

From technology demos and tech talks to awards and arcade games, Amerimold had much to offer industry this year.

-

Win the Haimer Photo Contest!

What is the Haimer marmot up to now?

-

Accuracy and Surface-Finish Needs Drive Cutting-Tool Solutions

Cutting-tool suppliers are using advanced coatings, new thread designs, education and collaboration to help moldmakers maximize results.

-

2018 Technology Review and Sourcing Guide: Cutting Tools

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including cutting tools.

-

2018 Technology Review and Sourcing Guide: Inspection/Measurement

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including inspection/measurement.

-

Scenes from Amerimold 2018, Part 2—Education!

MMT brings readers yet another look at Amerimold 2018. This time, the focus is on education via our Tech Talks, technology demos and more.

-

Connecting Mold Builders and Buyers at Amerimold 2018

Mold buyers and builders experience many of the same challenges for which they are each seeking solutions and that is where Amerimold comes into play.

-

Tradeshow Tuesday: On Display at Amerimold 2018, Part 5

Amerimold 2018 is just around the corner, so check out this week’s slideshow of items to see some of what will be on display at the show.

-

End Mill Has Helix Design to Reduce Machining Vibration

Basic Mill solid carbide end mills from Haimer USA are created with H6 shank tolerances using geometries with an unequal flute and helix design that reduces vibration while machining.

-

Get Up Close and Personal with Technology Demos at Amerimold

On top of our show floor Tech Talks, the event offers attendees the opportunity to see live presentations at select exhibitor booths on a specific technology or process, while demonstrating how it works live on the show floor.

-

Why You Need a Tool Presetter

Reduce machine idle time with fast, accurate, repeatable, offline cutting tool measurements.

-

Shrink-Fit System Helps Moldmaker Boost CNC Accuracy, Productivity and Tool Life

Fine tuning a CNC machine for maximum speed and having the ability to run lights-out machining means controlling a wide variety of elements like tool holding. The inherent benefit of shrink-fit technology, as compared to other tool holding options, is that it virtually eliminates the toolholder as a variable for error.

-

Pre-Machining Best Practices for Industry 4.0

Emphasis on technology that streamlines processes and provides repeatable outputs in your machining operations is key to automation and data-driven intelligence. Here are some common pre- and in-process attributes to consider as they pertain to process efficiency and reliability.

-

Technology Showcase: Heading to Westec?

If you’re planning to head west to attend Westec, billed as “the West Coast’s Leading Manufacturing Event,” today’s blog is a slideshow preview of products you can expect to see there.

-

Amerimold 2017: Multitudes of Metalworking Materials and Machines

Amerimold proved once again that it is THE event for moldmaking.

-

US Headquarters Positions Haimer as Source for Cutting Tool Tech

Check out this slide show from the recent Open House held by Haimer to officially unveil its new North American Headquarters in Chicago.

-

Balancing Act

Consider elements of the entire tooling assembly, including the tool, holder and holder components, to optimize productivity.

-

Unbalanced Perceptions

You may not realize it, but a balanced toolholder assembly can help you get the most from your machine tools.

-

Kennametal and Haimer Sign Agreement to Supply Kennametal’s Breakthrough KM4X Spindle Connection

Manufacturers to benefit from combination of leading toolholding and spindle connection solutions.

-

Manpower, Machine Time Maximized with Highly Accurate VMC

“Using highly accurate machines allows more efficient utilization of manpower and machine time—saving time and money for the customer and making BPM more profitable.”

-

Faster Machining Time with the Right Toolholders

In order to increase the productivity of the milling process in a die and mold company, one cannot concentrate only on the high performance machining centers. The tool holders can also help with savings. This is exactly what happened at the die and mold company Langer GmbH & Co. KG. With the help of the high quality HAIMER Power Shrink Chucks the total machining times on several applications were reduced almost in half.

-

A New Standard for Roughing in Moldmaking

A look at how to use modern toolholding technology with assurance that the cutting tool will not pull-out and how to increase feeds and speeds during heavy roughing.

-

Kennametal to Offer Safe-Lock system from Haimer

Kennametal will be offering its customers these benefits in the near future. The global cutting tool company has signed the respective license and will be presenting its Safe-Lock solutions at the EMO show in Hannover.

-

Tool Balancing and Shrink-fit Holders Yield Successful Manufacturing Platform Overhaul

Investing in technology while improving processes and methods yields near 100 percent success rate on initial mold trials and 50 percent reduction in shop rework and scrap.

-

Market Looks Razor Sharp

Great strides continue to be made in the cutting tool/toolholder market that result in reduced benchtime and additional handwork, as well as heavier depths-of-cut—adding up to increased productivity and higher accuracy.

-

Shrink Fit: The High Accuracy Toolholder of Choice

Requirements in the mold industry are much more precise than general machining, so more attention must be paid toward the selection of the appropriate toolholder in regards to its features and benefits.