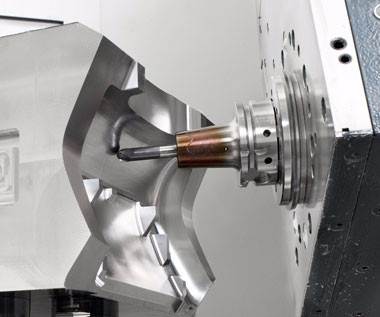

Polishing takes good old-fashioned man-hours that often cannot be avoided. However, using Haimer tooling, a mold builder can reduce polishing with superior surface finishes. In this “no polish required” scenario the cost savings for Omega Tool was $6,400. Photo Credit, all images: Omega Tool Inc.

Being average is never an option at Omega Tool Inc.—a high-precision plastic injection mold builder located in Menomonee Falls, Wisconsin. The team designs and manufactures small- to medium-sized plastic injection molds primarily for the medical, packaging and light industrial industries and depends on Haimer’s toolholder and shrink-fit system quality to achieve its high standards.

Like any other company, Omega Tool Inc. tried to lower upfront costs by investing in lower quality shrink-fit toolholders to maintain competitive pricing against the competition. However, the team quickly learned that initially saving money does not mean a shop will continue to save in the long term.

“The other shrink-fit toolholder brands we used had short life expectancy, especially with smaller diameters,” Omega Tool Inc.’s vice president of operations, Randy Lee Meissner, explains. “Too many times we had tooling that would not release from the shrink-fit toolholder, which I attributed to the inferior steel and looser tolerances.”

The shrink-fit system Omega Tool used before involved submerging the heated toolholder in a bucket of coolant. While the coolant, which shocked the system, contributed to shorter toolholder life, it was also very messy.

Power Clamp Shrink-Fit Machine

When Omega Tool decided to invest in another toolholder and shrink-fit system, they looked to Haimer, purchasing two power clamp special-edition shrink-fit machines that employ a cooling manager.

Mold builders can simplify the shrink-fitting process with a power clamp machine, standard shrink holders and a standard automatic shrink setting.

According to Haimer, the second the user starts to shrink a tool, a refrigeration unit below turns on circulates coolant through five cooling bodies (1/8 inch to 1 ¼ inches).

This machine also uses a coil with stop disc technology—five stop discs from 1/8 inch to 1 ¼ inches. A user can simply choose a stop disc that is slightly larger than the cutter, for example, a ¾-inch disc.

When using this power clamp machine, you are also using standard shrink holders and a standard automatic shrink setting, which simplifies the process. After the tool is shrunk and the power button is hit, two beeps will sound. The first one pings the material to measure the size and the second one heats the tool. After about three to five seconds, the cutter can be swapped out. There is no need to set any electronics; it is a one-button operation.

The system also gives the user plenty of time to grab and insert their next cutter. After insertion, the chuck support can be slid over to the cooling area in order to take the appropriate cooling body and place it over the holder. While the tool is cooling (30 to 40 seconds), the user is able to grab the next tool.

For example, for a 10-millimeter tool, a user can change the stop disc out by simply dropping it in, then turning it a quarter to bring the coil down until it touches the top of the tool. Within a few seconds, the tool cools and the cutter is removed. This is a preset cycle, so there is no opportunity to overheat the holder.

A power clamp machine yields consistency in cutting tool setups.

“The reason for switching was simple—quality. There isn’t a toolholder on the market that has the consistent repeatability of a Haimer toolholder,” Meissner says.

After using this machine for a while, Omega started to notice the consistency with which the machine could set up cutting tools. “It was immediate! These blocks are just one recent example of a ‘no polishing required for molding’ surface finish,” Meissner says. “The core and cavity blocks represent one mold build. This project was two almost identical tools, totaling eight blocks.”

Regardless of the operator and their experience level, the results maintained repeatable uniformity in tooling setup and equally consistent results.

Haimer guarantees <3μm runout at 3xD and this degree of accuracy is repeatable for any number of operators from shift to shift. “The cooling and heating time are consistent. This machine is a workhorse. It has never broken,” Meissner says.

Shrink-Fit Toolholders

For its ultra-precision machining, Omega Tool Inc. also invested in HSK-E40, HSK-63A, CAT40 and CAT50 Haimer shrink-fit toolholders. It wasn’t long before the team noticed a difference. “When it comes to part size accuracy, surface finish and tool life, the difference between a Haimer heat shrink and its competitors is night and day,” Meissner says.

The shrink-fit toolholders significantly ease processes regarding tool runout, reach and clamping force. “The main reason we use heat shrink is to reduce runout and increase rigidity. Coolant-through drilling applications and a Hamier heat shrink mean near-complete confidence that runout is eliminated,” Meissner notes. “ Milling is even better since runout is under 0.0001 inch. Tools cut naturally, which allows more aggressive HEM [high-efficiency machining], higher SFM [surface feet per minute] and consistent tool wear with superior surface finish.”

In addition, the uniform pressure on the cutting edges in the Haimer shrink-fit toolholders is said to yield better dimensional accuracy, surface finish, smoothness and tool life. “This means I do not have to polish the mold in many instances. Instead, I can mold right off of the finish with the Haimer tooling,” Meissner says.

Shrink-fit toolholders significantly ease tool runout, reach and clamping force.

Haimer’s toolholder’s slim profiles are another great feature. “Certain features in plastic molding applications, especially gates, are extremely impractical to cut without the use of the Haimer’s slim holders because they allow the holder to get much closer to the feature with significantly less tool stick out,” Meissner says.

Haimer uses unique raw materials for the toolholders verified with spectral analysis. These materials offer high strength and high toughness, making them an excellent fit for the requirements of shrinking technology. As a result, a machinist can shrink in and out with repeatable accuracy as often as they would like.

“I tried to make the Haimer toolholders fail. I overcooked them to see if I could make them fail and I couldn’t,” Meissner concludes.

Related Content

Precision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

Read MoreHow to Optimize Mold Finishing

Circle segment technology requires fewer tool paths, improving surface quality and increasing cutting tool life.

Read MoreBuilding Molds: Most Popular Reads of 2024

Dive into the most-viewed content for building your mold, including topics such as cutting tools, EDM, hot runners, additive manufacturing, mold materials, machining and mold components.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreRead Next

Why You Need a Tool Presetter

Reduce machine idle time with fast, accurate, repeatable, offline cutting tool measurements.

Read MoreVIDEO: How Can Moldmakers Benefit By Integrating Industry 4.0 into Their Machining Processes?

MoldMaking Technology Senior Editor Cynthia Kustush chats with Brendt Holden, president of Haimer USA, about Industry 4.0 and how moldmaking companies can embrace and prepare for using the tools of connectivity to increase machine utilization and overall productivity.

Read MorePre-Machining Best Practices for Industry 4.0

Emphasis on technology that streamlines processes and provides repeatable outputs in your machining operations is key to automation and data-driven intelligence. Here are some common pre- and in-process attributes to consider as they pertain to process efficiency and reliability.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)