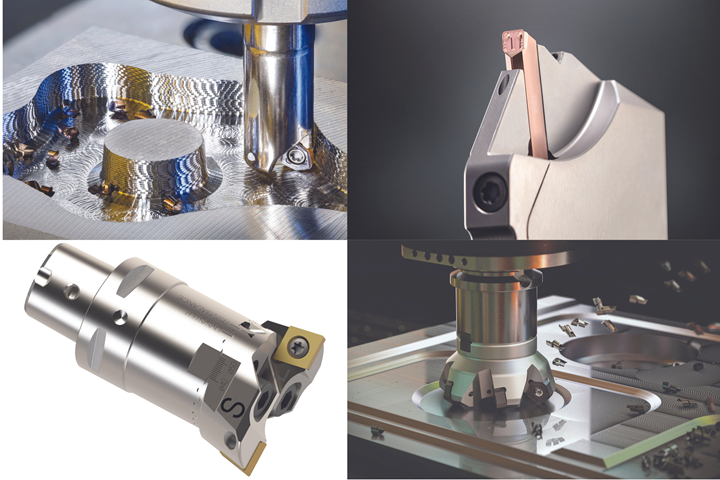

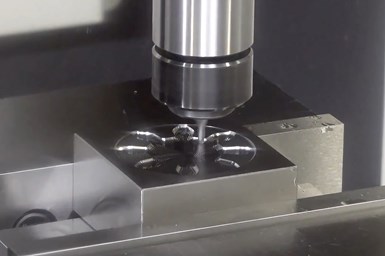

Photo Credit: (top left) Iscar USA, (top right) Horn USA, (bottom left) Big Kaiser and (bottom right) YG-1.

Cutting tool selection for mold manufacturing operations is critical, as it will be reflected in quality, repeatability and productivity, as well as the effectiveness and longevity of the tool itself.

There are an abundance of cutting tool choices on the market to suit mold builders’ needs, some of which are identified below and can be found in MoldMaking Technology’s January 2022 print/digital issue. Indexable tools, milling tools with high feed rates, cutting tool catalogs, end mills, geometry inserts, boring heads, face milling, toolholders and more with new designs, coatings and material types are offered by well-recognized companies.

For the full product post, click on each linked title, or find it under the “New Tech” section of the website. Don’t miss out on a compilation of additional cutting tool offerings later this month.

Cutting Tools

Iscar’s new family of Micro3feed indexable tools have been designed to replace solid carbide end mills. Intended for the productive rough milling of compact parts, small-in-size cavities, pockets and more at high feed rates, Micro3feed is applicable in die and moldmaking and the manufacture of miniature parts and small components, among other applications.

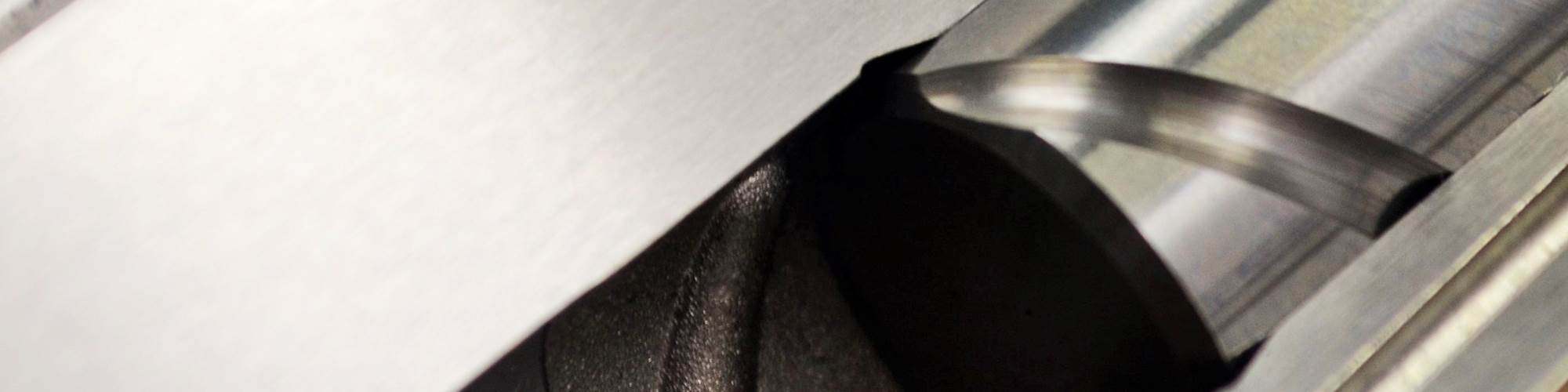

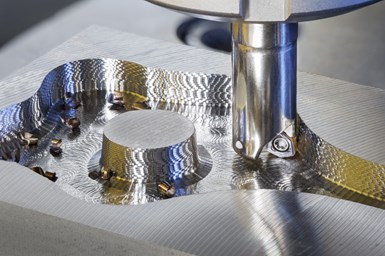

Photo Credit: Sandvik Coromant

Sandvik Coromant has launched a new high-feed milling tool. The CoroMill MH20 is primarily designed for milling cavities, or pockets, in ISO S, M and P materials. Ensuring secure and vibration-free machining, especially at long overhangs, the CoroMill MH20 is said to deliver best-in-class edge security for a variety of industries.

Emuge-Franken N.A, a manufacturer of high-performance taps, thread mills, drills, end mills and other rotary tools, has announced the launch of a new full line 172-page end mills catalog to support its growing end mill products expansion.

Photo Credit: Emuge-Franken N.A.

Focused on the needs of today’s mold builders, M.A. Ford has developed the TuffCut 3D, 250 Series end mill. This two-flute, high-performance ball nose design is geared toward precision 3D machining in steels that are ≤50 Rc.

The 156 Series features geometry that is focused on hard milling in the 52-65 Rc range, which has the tendency to cause smearing and premature tool wear when working in these softer materials.

Haimer USA has invented Safe-Lock, an EDM form in a shrink fit holder. Unlike friction-based toolholding systems, Haimer notes, when the operator shrinks the holder to insert a cutting tool using Safe-Lock, it engages the Safe-Lock form which includes the grooves on the back end of the cutting tool and a matching EDM form in the holder in the rear of the bore.

Photo Credit: Sumitomo Electric Carbide Inc.

Sumitomo is expanding its existing SMD Replaceable Tip Drilling line with new SMDT-NAL drill tips. SMDT-NAL features the proprietary diamond-like Carbon DLC ‘Aurora’ Coating. These replaceable drill tips are suitable for machining aluminum alloys and non-ferrous materials. SMD holders include deep-hole drilling up to 12 XD standard and the SMDT drill tip lineup offers diameters ranging from fractional sizes 15/32 to 11/4.

Photo Credit: Ingersoll Cutting Tools

The DiPosFeed series of indexable high-feed mills by Ingersoll Cutting Tools are said to offer extreme milling performance. Key features include four insert sizes, grades for all materials, three different cutting-edge preparation options, strong radius high-feed insert geometry and fine and coarse pitch cutter capabilities.

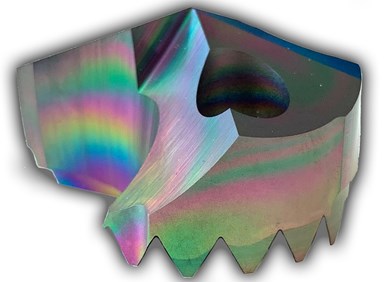

Photo Credit: Horn USA Inc.

Horn USA has released novel high-performance tool coatings IG6 and SG3 that are less than 0.005 mm (0.0002″) thick and aid in extending the service of carbide tools.

IG6 is a copper-colored aluminum titanium silica nitride (AlSiTiN) coating designed for use in machining materials P and M. SG3 is designed for use in titanium and superalloys as well as turning and grooving applications in hardened materials, up to 58 HRC.

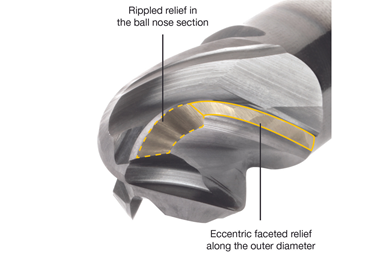

Kennametal introduces an expansion to the Harvi I TE series, with the addition of a four-flute ball nose end mill. Designed for highly productive 3D roughing and finishing operations—including for mold machining—Kennametal says it delivers low machining cost through maximum metal removal in a broad range of materials.

Walter USA highlights the Xtra-tec XT M5009 face milling cutter for face milling, roughing and rough finishing with wiper inserts on steel and stainless steels materials with difficult cutting properties, as well as non-ferrous metals.

The M5009’s small, tough, double-sided SN X0904 or SN X1205 indexable inserts and high number of teeth enable the cutter to maximize feeds, tool life and productivity and boost process reliability, Walter notes, while also reducing cutting tool material costs.

Tungaloy America unveils its DoFeedTri high-feed milling cutters, which use double-sided inserts with six total cutting edges—three cutting edges on each side—enabling what Tungaloy says is further machine cost reduction, more economic milling and 1.5 times better cost per edge than conventional inserts with four cutting edges.

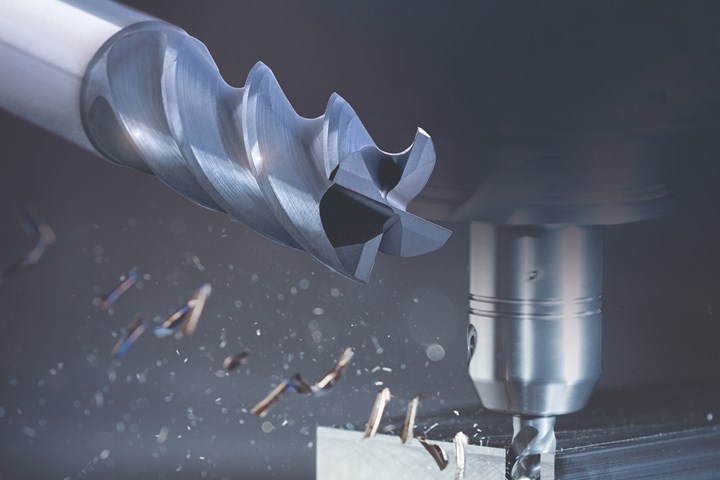

For optimum metal removing in soft, tough or high-alloyed materials commonly used in moldmaking, Guhring Inc. introduces the RF 100 Sharp carbide end mill. With a rake angle of 12º, the company says the sharp milling cutter offers reduced cutting forces and tool pressure. The RF 100 Sharp excels in slotting, roughing, ramping and helical interpolation in free machining steels, stainless steels, tough special alloys and higher strength aluminum alloys.

Photo Credit: Guhring Inc.

Big Kaiser Precision Tooling presents the Series 319 SW rough boring head with Big Capto connection—a dual contact modular turning and rotating toolholder system—which the company says makes it possible to seamlessly perform rough and finish boring processes.

Photo Credit: Allied Machine and Engineering

Allied Machine and Engineering has expanded its T-A Pro high-penetration drilling system to include the high-speed steel geometry insert commonly referred to as the “X” geometry. This cobalt insert works as a drill-everything insert while lowering the risk for high-dollar value components, the company contends. When functioning in less than ideal conditions, the high-speed steel geometry is said to provide optimal performance and chip formation in addition to process security.

Photo Credit: Platinum Tooling Technologies

Platinum Tooling Technologies Inc., the North American importer of standard and custom live tools, angle heads and multiple spindle tools manufactured by heimatec GmbH, has released its new tooling catalog.

The catalog offers an updated look and features the company’s high-quality machine tool accessory lines.

Photo Credit: GWS Tool Group

GWS Tool Group introduces the Hurrimill AT4 all-terrain end mill, a four- flute high-performance solid carbide end mill for ferrous and non-ferrous applications. Whether its slotting, profiling, ramping, plunging, roughing, finishing or high-speed milling, the end mill is designed to traverse a wide range of materials in a wide range of machining environments.

Photo Credit: Techniks Tooling Group/Parlec

To counter the challenges of shrink-fit tooling—including upfront cost, and potential tool setup bottlenecks—and provide a cutting tool solution with narrow nose diameters, Techniks Tooling Group’s acquired tooling division, Parlec, offers the Micron Mold-Style (M-Style) Milling Chucks. Parlec milling chucks were created for mold machining and feature narrow nose diameters, down to 0.35", reportedly providing the clearance needed to machine difficult-to-reach areas and avoid other mold features or obstructions.

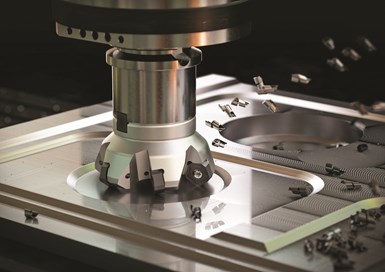

YG-1’s newly introduced FM10 PNMU face milling indexable inserts combine multi-corner face milling performance with high feed capabilities.

The FM10 PNMU inserts are designed to separate the cutting edge and the wiper, which results in ten true cutting edges.

Photo Credit: U.S. Union Tool

Over the last few years, Union Tool says, the demand for extended life of molds and dies has led to the supply of new technologies that meets the machining needs of cutting high hardness and/or abrasive alloys with accuracy, extended tool life and cost-efficient programs.

Over a year ago Union Tool launched the HGB/HGLB ball nose series, which is said to have met these goals. More recently, the company release a four-flute, long neck radius end mill series, HGLRS 4000, for a corner radius option.

.png;maxWidth=300;quality=90)