Cutting Tools Portfolio Caters to High Machining Demands

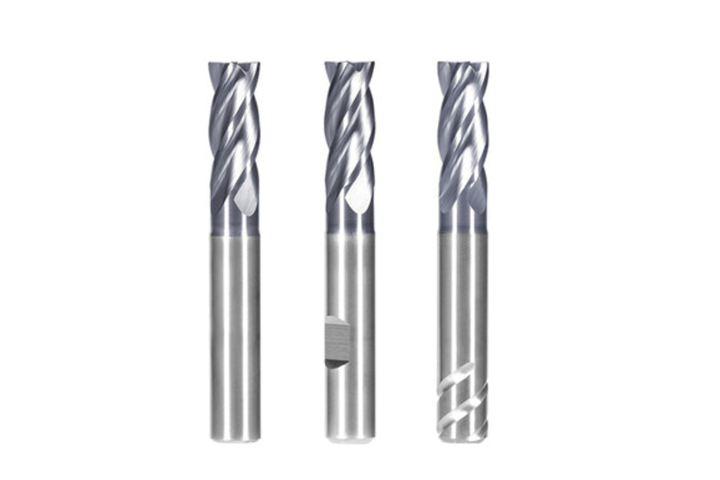

The Haimer Mill line offers a variety of entry-level cutting tools for roughing and finishing that deliver precision, reliability and efficiency.

The Haimer Mill line offers a range of cutting tools that provide precise and reliable machining for ramping, drilling, milling or slotting operations. These characteristics, according to Haimer USA, make the line an optimal choice for professionals looking for entry-level cutting tools that offer efficient and cost-effective machining solutions.

Haimer Mill solid carbide end mills are characterized by their reliability, versatility and precision. They are adaptable and suitable for use in almost all materials, the company contends, making them ideal for efficient roughing and finishing operations in industries like automotive and medical. The end mills also provide accuracy and consistency for high-quality and consistent parts production.

The Haimer Mill line complements the solid carbide end mills with an array of chamfering end mills, designed to produce an optimal surface finish and precise angles, adding a high level of intricacy to any machining operation. A variety of sizes and configurations are available so that end users are able to select the best tool for the correct specific applications and enhance the quality of their work.

Related Content

-

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

-

The Secrets to Hard Milling Success

The Secrets to Hard Milling Success

.png;maxWidth=300;quality=90)