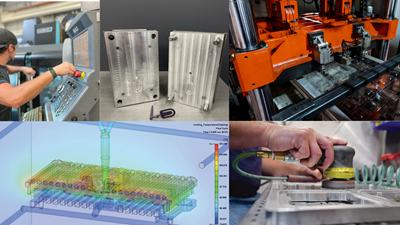

End Mills, Drills, Inserts and More for Mold Building Needs

This list of cutting tool-related products that MMT editors have recently published provide readers a good look at what is being offered in the industry for their everyday operations.

Cutting tools, including end mills and carbide inserts, for example, are indispensable for everyday mold builders, as they literally shape and define the intricate features of molds with precision.

Importantly, the selection of appropriate cutting tools directly influences the quality, efficiency and accuracy of the mold building process. Staying up to date on the latest advances in cutting tool technology is paramount in order to benefit from innovations that enhance cutting speed, tool life and overall performance. Keeping abreast of advancements ensures that mold builders can leverage state-of-the-art tools, optimizing their machining processes, reducing production time and ultimately maintaining a competitive edge in delivering high-quality molds within such a dynamic landscape.

With this in mind, MMT has gathered together a list of company products that editors have recently published under this category. While not an exhaustive list of what is available, it can give you a good look at what is being offered in the industry and current trends.

Below are excerpts from each product publication. For the full article, click the hyperlinked titles.

Sharpening Solution to Give End Mills New Life

Darex has been in the business of drill bit sharpeners for more than 50 years. Knowing that the average quality end mill easily costs several hundred dollars, the company is finally applying its sharpening expertise to an upcoming end mill solution in the form of a new attachment for its XT3000 drill sharpener.

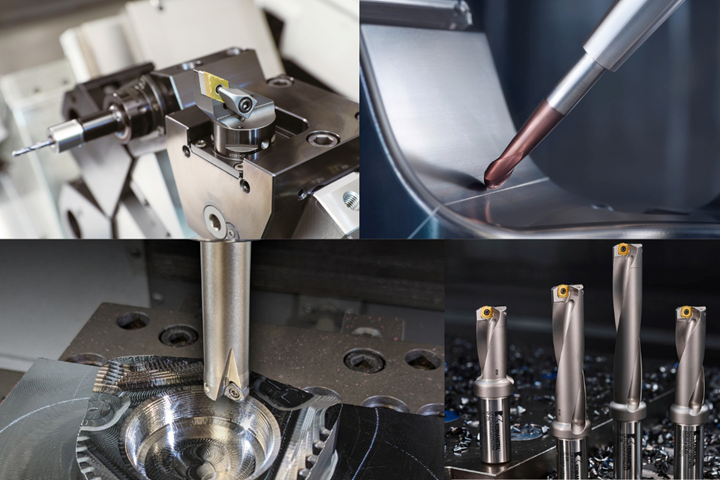

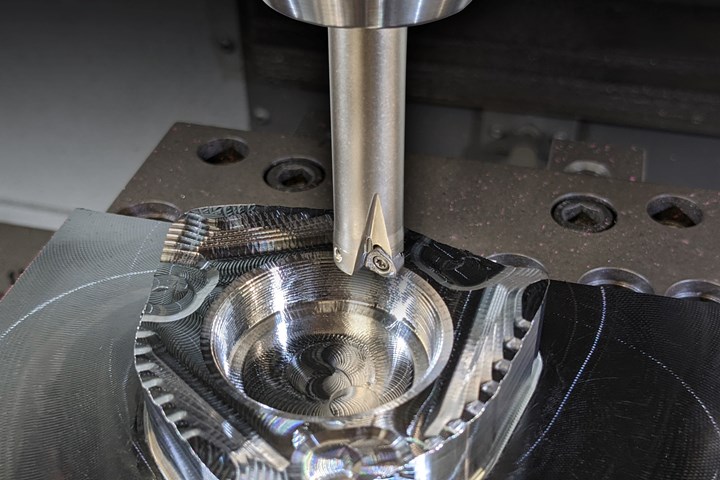

Milling Cutter Handles High-Precision Moldmaking Requirements

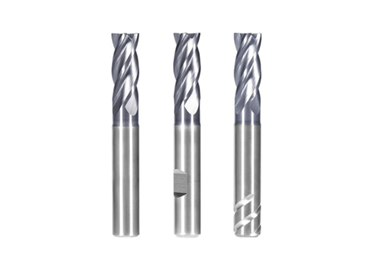

To meet exacting mold tolerance surface finish standards, moldmakers must rely on highly precise cutting tools and complex machining techniques. Guhring Inc.’s new G-Mold line of high-precision milling cutters offers a significant advantage in meeting these demanding requirements.

Mold and Die End Mills Target Hard Machining

Emuge-Franken’s line of hard-cut ball nose and torus end mills line offer significantly longer tool life, and optimal surface finishes in hard materials.

More than 20 new solid carbide end mills in the hard-cut ball nose and torus line provide high-performance milling in materials hardened up to 66-70 HRC, as well as in unhardened steel and cast materials. Due to optimized tool geometry and high-performance solid carbide construction, the end mills offer up to 60% longer tool life and produce the highest quality surface finishes, according to the company.

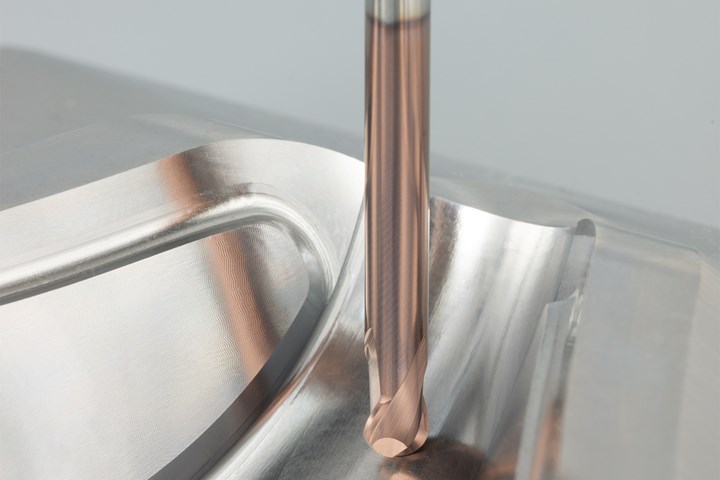

Ball Lens Inserts Are Engineered for Productivity, Surface Finish Gains

Millstar, a part of Cole Tooling System Inc., manufactures insert and solid carbide tooling for conventional profile machining, high-speed milling and hard milling. The company highlights its ABL series inserts, which use an innovative hybrid ball lens design to provide a large end face radius — typically equal to the diameter. This enables up to twice the stepover during machining operations, decreasing cycle time without sacrificing surface finish.

Indexable Milling Platform Advances Mold and Die Capabilities

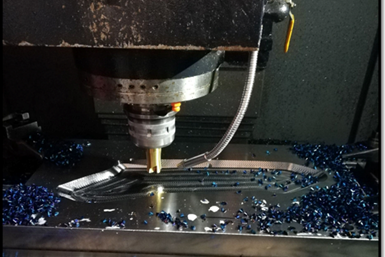

Since its debut at IMTS 2022, Dapra Corp. announces that its Vapor high-feed indexable milling platform has become a quick favorite among many of the company’s North American mold and die and production shop customers.

Vapor delivers high metal removal rates across all mold roughing applications by pairing light depths of cut and high feed rates, increasing the number of teeth in the cut to capitalize on modern machine tool capabilities.

Tool Balancing Equipment Ensures Consistent Moldmaking Results

The Zoller Inc. »toolBalancer« series delivers an advanced tool balancing system that enables moldmakers to achieve high-quality surface finishes and extend the life of cutting tools and machine tool spindles.

The »toolBalancer 550« and »toolBalancer 750« can balance toolholders, tool assemblies and grinding wheels within 0.4 gmm of accuracy, enabling smooth machining that protects the machining center and produces a better part. Machines in this series can balance tools weighing up to 66 lbs with diameters up to 18.9" and lengths up to either 21.6" (»toolBalancer 550«) or 29.5" (»toolBalancer 750«).

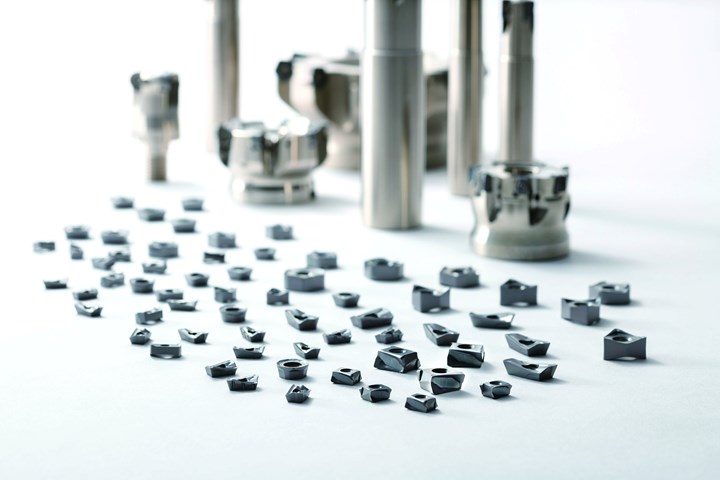

PVD-Grade Carbide Milling Inserts Address Mold Machining Challenges

Walter USA introduces its Tiger·tec Gold physical vapor deposition (PVD) grade WSP45G, a new generation of indexable carbide inserts for milling that dramatically expands capabilities for slotting, shoulder and copy milling. The new grade can efficiently process demanding machining applications such as interrupted cuts and difficult materials, desirable for mold building, when mold component interchangeability, ever-tightening tolerances and hardened tool steels are common.

Indexable Drill Offers Extended Application Range

Kennametal Inc. has upgraded its Drill Fix indexable drilling platform with Drill Fix Pro, offering customers a cost-effective solution for a wide variety of drilling operations.

“When it comes to performance, Drill Fix Pro is the overachiever in our indexable drilling portfolio,” says Michael Hacker, Kennametal’s senior global product manager. “It delivers superior surface finish, hole quality and chip evacuation plus increased versatility for a broad range of customers’ needs.”

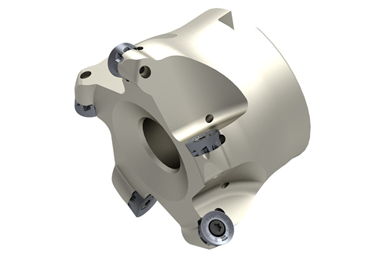

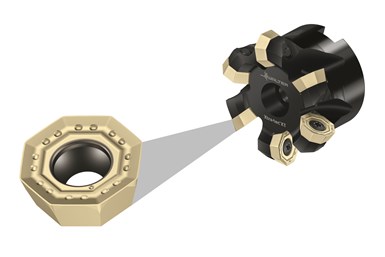

Cutter Designed for Roughing in Face, Profile Milling Operations

Sandvik Coromant has launched a new milling concept — the CoroMill MR80 — primarily designed for challenging roughing operations in a wide range of face and profile milling applications in steel and stainless steel. The MR80 is also recommended for tool steels. Hardened tool steels are not a primary use example, but are still applicable for the MR80 cutting tool.

Flat Bottom Drill Supports Stable Counterboring Action

OSG USA Inc. announces the expansion of the company’s Phoenix PDZ offering with the addition of the new PDZ-3D indexable flat drills. The flat bottom drills feature enhanced chip breaker geometry, resulting in improved chip formation and evacuation. The broad lineup includes standard socket head cap screw sizes, enabling fast and stable drilling of counterbores in mold bases.

Solid Ceramic End Mills Provide High Metal Removal Rates

Greenleaf Corp. highlights its Xsytin-360 end mills — a cutting tool that combines the company’s phase-toughened Xsytin-1 substrate with a specialized cutting geometry that is said to offer 10X higher productivity. The strength of the material enables the user to apply chip loads similar to solid carbide end mills with higher speeds common to ceramic machining. These new ceramic end mills provide increases in productivity over current solid carbide or ceramic products.

Related Content

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreAdvantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

Read MoreIt Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read MoreTreatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

Read MoreRead Next

2024 Outlook: Anticipating Trends and Opportunities for Mold Builders

The January 2024 issue lineup sets the tone for the variety of topics, technologies and trends that we will cover this year.

Read MoreTechnologies for Maintaining, Repairing and Surface Treating Your Molds

This technology roundup covers everything from laser repair and mold protection coatings to in-house maintenance services and education tools for learning best practices behind taking care of injection molds.

Read MoreProducts/Services for the Everyday Mold Builder

Happy New Year! MMT is bringing back its monthly technology/service roundups. Learn more about new and familiar companies, and the products available to the moldmaking industry.

Read More.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)