January 2024 Issue

January 2024

Digital Edition

Features

Featured articles from the January 2024 issue of MoldMaking Technology

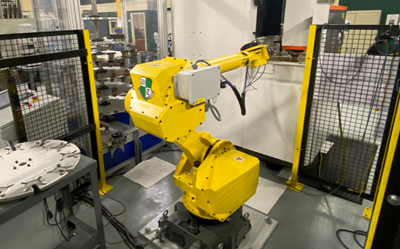

3 Technologies to Help Fill the Skills Gap

Moldmakers can address the labor challenge with robotic systems, simulation products and metal 3D printers.

Read More

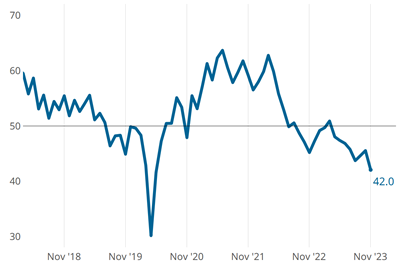

November GBI Saw a Drop in Moldmaking Activity

The moldmaking index experienced a high degree of accelerated contract, primarily driven by production, new orders and backlog readings.

Read More

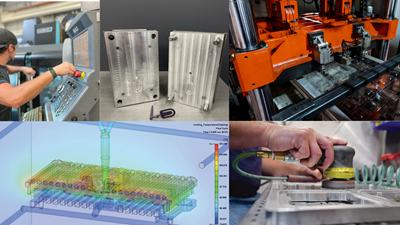

2024 Outlook: Anticipating Trends and Opportunities for Mold Builders

The January 2024 issue lineup sets the tone for the variety of topics, technologies and trends that we will cover this year.

Read More

Electroform and Hononegah High School Partner for Hands-On Moldmaking Education

Electroform teamed up with Hononegah High School to give engineering and manufacturing students a hands-on moldmaking experience — including the design process, machining of components, assembly and mold sampling.

Read More

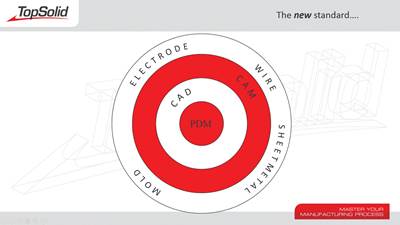

Managing all That Data

Product data management may have a bad rap, but making it a priority rather than an afterthought can help make the most of your design and machining information.

Read More

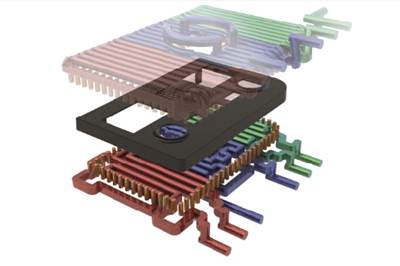

Innovative Mold Building Enhances Packaging Material Efficiency, Elevates Recyclable Design

A manufacturing-focused design and optimized tooling enhance material efficiency in packaging for a new medical instrument.

Read More

How to Use Simulation to Achieve a High-Gloss Surface Finish

Combining simulation, conformal cooling, and a rapid heat and cooling process can predict and produce the required surface finish for high-gloss plastic parts.

Read More

How to Use and Protect Remote Machine Monitoring Data

Collecting, analyzing and securing machine data in real time can substantially improve productivity, profitability and customer satisfaction.

Read More

Editorial Advisory Board 2023-2026: Meet New Board Member Gabe English, Western Carolina Tool & Mold

The 2023-2026 version of MoldMaking Technology's EAB features a new crew of industry professionals. Meet Gabe English

Read More

A Passion for Innovation in High-Precision, Multi-Cavity Moldmaking

Boucherie uses its dedicated R&D facility to develop new mold, machinery and automation technologies to stay ahead of the competition.

Read More

.jpg;maxWidth=300;quality=90)