High-Feed Milling Cutter Range Benefits Moldmaking Versatility

Horn USA offers a comprehensive DAH milling tool range, including the DAH37 high-feed cutter, DAH82 and DAH84 carbide grades and the DG range.

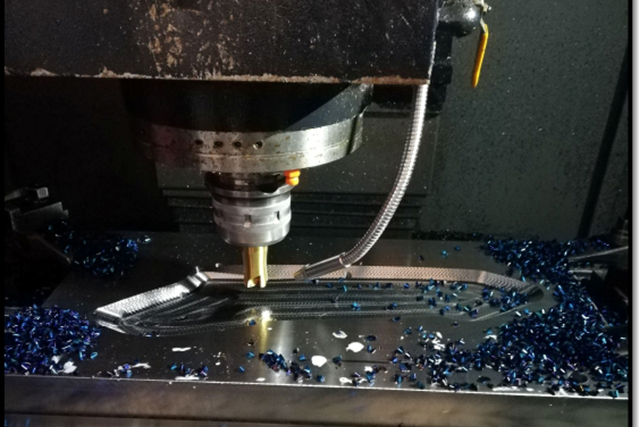

Photo Credit: Horn USA

Aiming to deliver cutting tool solutions that redefine the moldmaking landscape, Horn USA is offering its comprehensive DAH milling tools, which offer a range of capabilities including ramping, surfacing, plunge milling, helicoidal drilling and 3D machining.

The DAH37 high-feed milling cutter, for example, features three cutting edges and is fortified with SA4B and SC6A coatings, making it versatile for machining various materials. The DAH82 carbide grade, boasting eight cutting edges, and its counterpart, the DAH84 with a greater depth of cut, represent the latest advancements in high-feed milling technology from Horn’s location in Germany — the tools have showcased high performance globally, making their mark in countries like France, Morocco, China, Spain, Italy, Vietnam and the U.S. In Vietnam, for instance, the DAH milling cutters have become indispensable for machining molds for the exhaust pipes of motorcycle brands and crafting molds for everyday items such as spoons and forks.

The DAH82 variant is available as an end mill and as a screw-in milling cutter in 20-, 25-, 32-, 35- and 40-mm diameters. For diameters in excess of 50 mm and up to 125 mm, the larger DAH84 system is used. All tool bodies receive a special surface treatment for high strength and hardness, imparting long-term protection against abrasive wear from chips.

The DG range, featuring replaceable screwed ends, is another option for mold builders, covering everything from diameter and roughing to finishing and high-feed applications.

According to Horn USA, adaptability is what sets its cutting tools apart — whether working with or without coolant, they offer improved tool life, and their lengths are easily adjustable, thanks to Horn’s steel or carbide toolholders, which seamlessly screw onto standard chucks.

Related Content

-

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

-

The Secrets to Hard Milling Success

The Secrets to Hard Milling Success

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.